Vacuum ultraviolet induced high colour purity red phosphor and preparation method thereof

A red phosphor, vacuum ultraviolet technology, applied in luminescent materials, chemical instruments and methods, etc., can solve problems such as insufficient luminous efficiency, and achieve the effects of good chemical stability, low cost, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of above-mentioned red fluorescent powder, comprises the following steps:

[0026] 1), the chemical formula M (1+x) M' (1-2x) BP 2 o 8 :Eu x The composition measurement ratio of the weighed raw materials is ground and mixed, that is, weighed according to the molar ratio of the corresponding elements in the above structural formula. Where 0<x≤0.3, M is one or more of Li, Na, K, and M' is one or more of Ba, Sr, Ca;

[0027] 2), roasting the above-mentioned mixed material at high temperature, and washing the sintered material;

[0028] 3) Separating and filtering the washed materials, and then classifying them according to their particle size;

[0029] 4) After drying the classified materials, red phosphor powder with high color purity can be obtained.

[0030] Wherein, the raw material of the step 1) is Li-containing compound or simple substance, Na-containing compound or simple substance, K-containing compound or simple substance, Ba-contain...

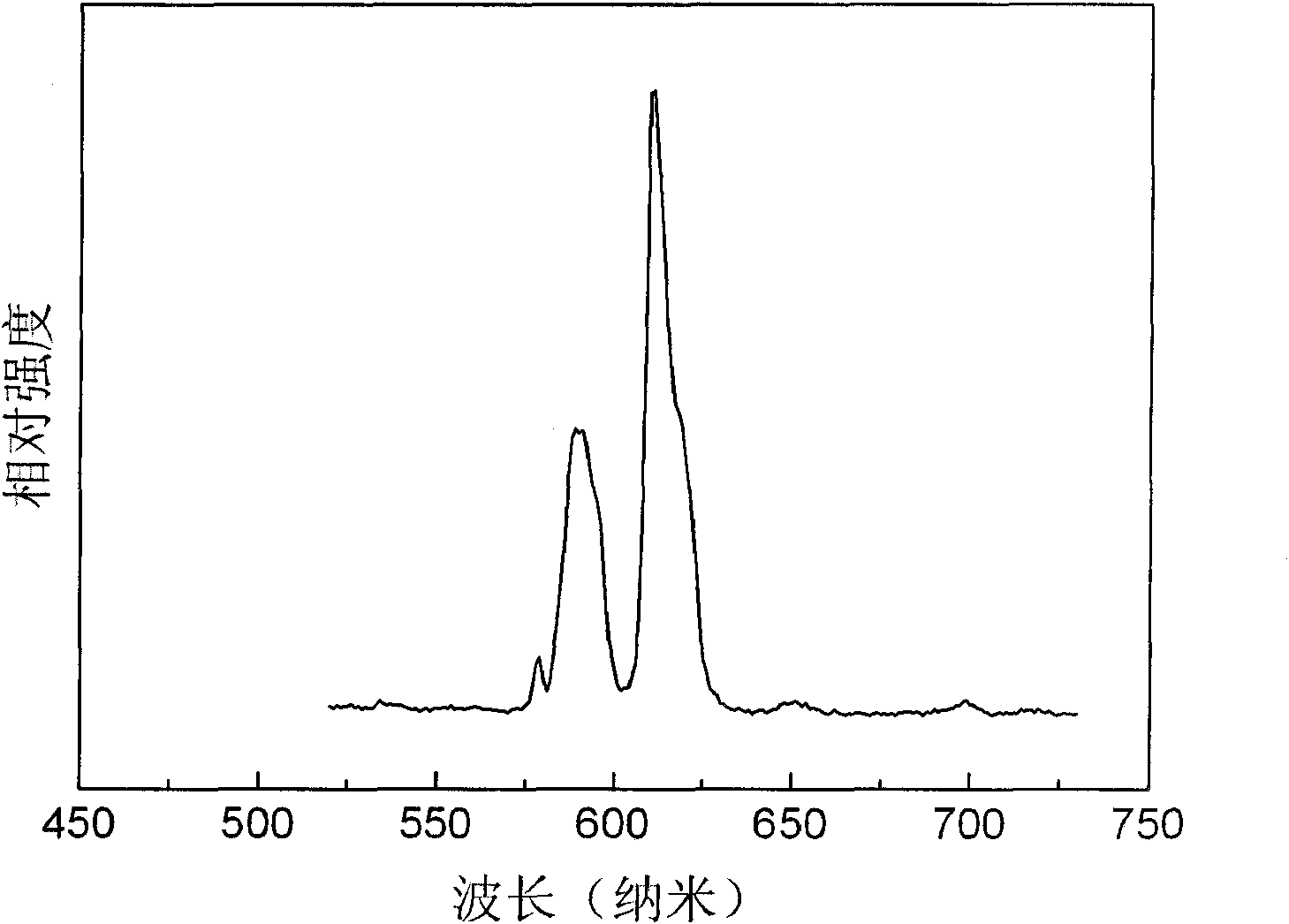

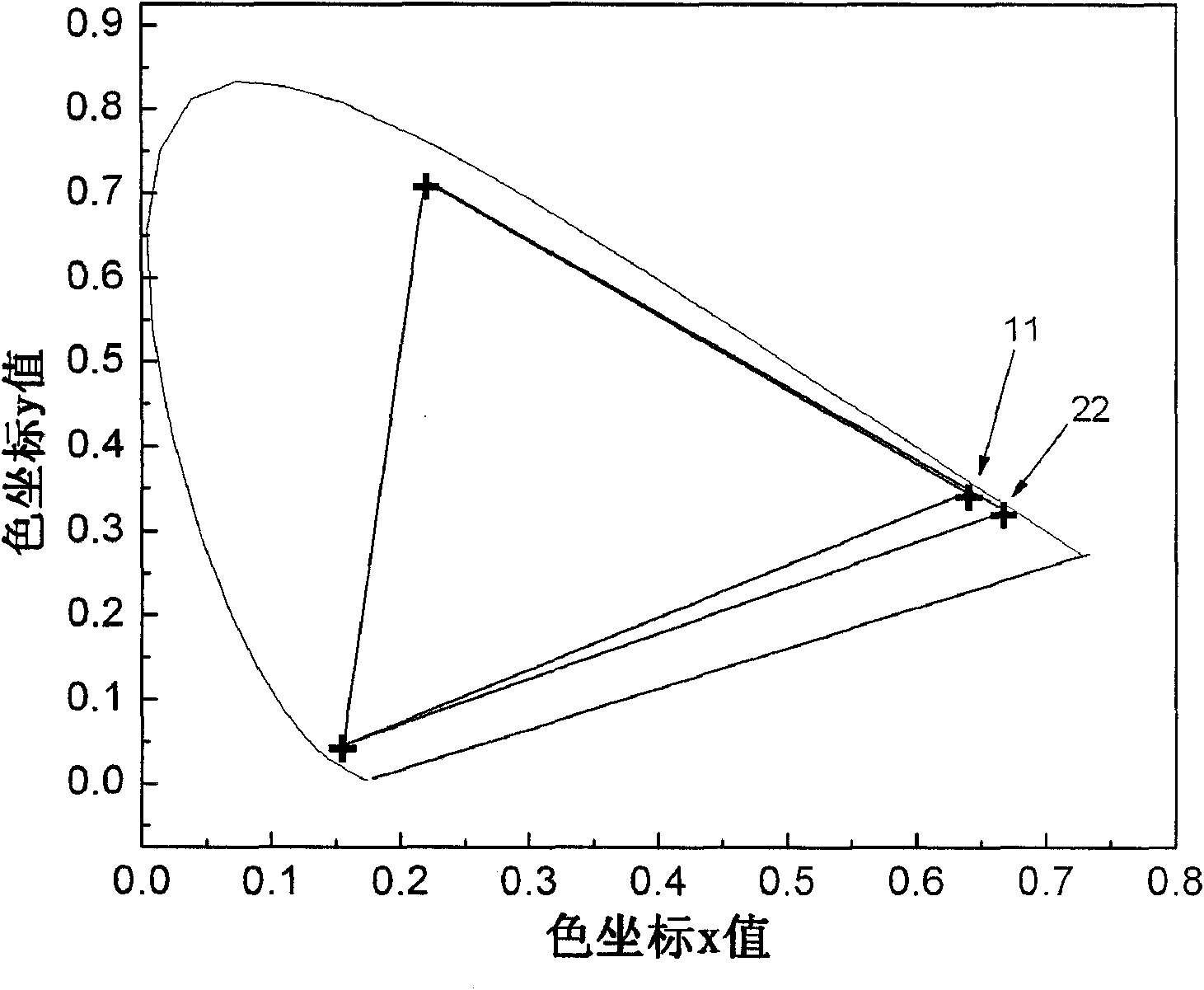

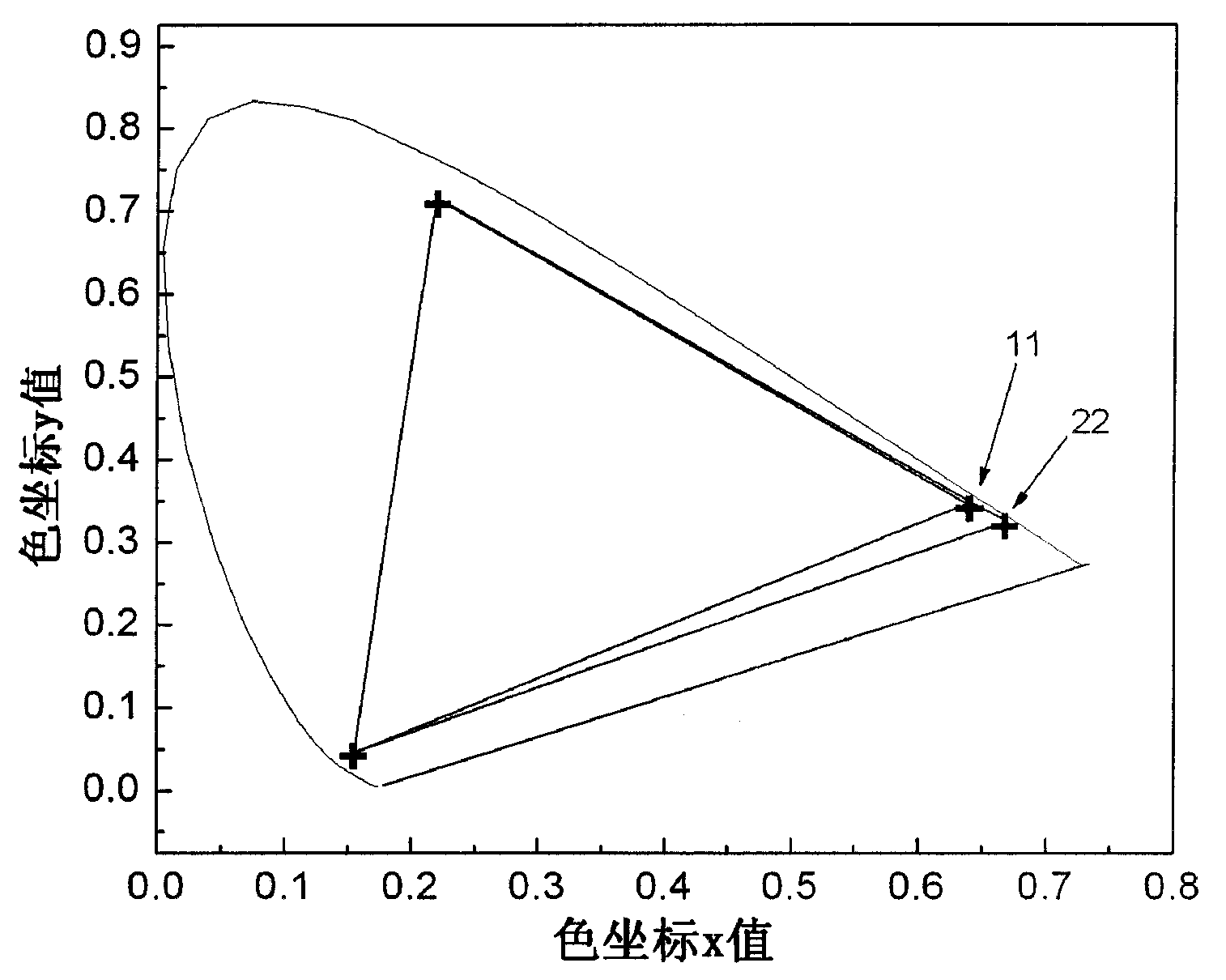

Embodiment 1

[0037] Embodiment 1: composition is Na 1.002 Ba 0.996 BP 2 o 8 :Eu 0.002 red phosphor

[0038] According to chemical formula M (1+x) M' (1-2x) BP 2 o 8 :Eu x Carry out batching, wherein: X=0.002, M is Na, M ' is Ba, then takes by weighing (NH 4 ) 2 HPO 4 、H 3 BO 3 , BaCO 3 、Na 2 CO 3 , Eu 2 o 3 After the raw materials are fully ground and mixed, they are first sintered in an air atmosphere at 400°C for 24 hours, taken out and mixed evenly, and then sintered in a reducing atmosphere at 800°C (volume ratio N 2 / H 2 =95:5) and sintered for 24 hours, cooled naturally to room temperature, took out and ground, washed with deionized water, carried out centrifugal filtration, and carried out liquid classification, selected powder particles with a particle size of 8-10 microns, and finally baked at 60°C Dry to obtain red phosphor for PDP.

Embodiment 2

[0039] Embodiment 2: composition is K 1.05 Sr 0.9 BP 2 o 8 :Eu 0.05 red phosphor

[0040] According to the chemical formula M (1+x) M' (1-2x) BP 2 o 8 :Eu x Carry out batching, wherein: X=0.05, M is K, M ' is Sr, then takes by weighing (NH 4 ) 2 HPO 4 、H 3 BO 3 , SrCO 3 、K 2 CO 3 , Eu 2 o 3 The raw materials are ground and mixed thoroughly, and then sintered in an air atmosphere at 600°C for 20 hours, taken out and mixed evenly, and then sintered in a reducing atmosphere at 800°C (volume ratio N 2 / H 2 =95:5) and sintered for 18 hours, naturally cooled to room temperature, took out and ground, washed with deionized water, carried out liquid classification after carrying out Buchner funnel suction filtration, and selected particles with a particle size of 5-7 microns, finally in 100 Dry at ℃ to obtain the red phosphor for PDP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com