Method for manufacturing three-dimensional nano grid structure based on one-dimensional soft template nanoimprinting

A nanoimprinting and three-dimensional nanotechnology, which is applied in the field of manufacturing three-dimensional nanogrid structures based on one-dimensional soft template nanoimprinting technology, can solve the problems of increasing the production cost of nanostructures, shortening the service life of templates, and damage to hard templates. Reduce production difficulty, reduce processing cost, and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

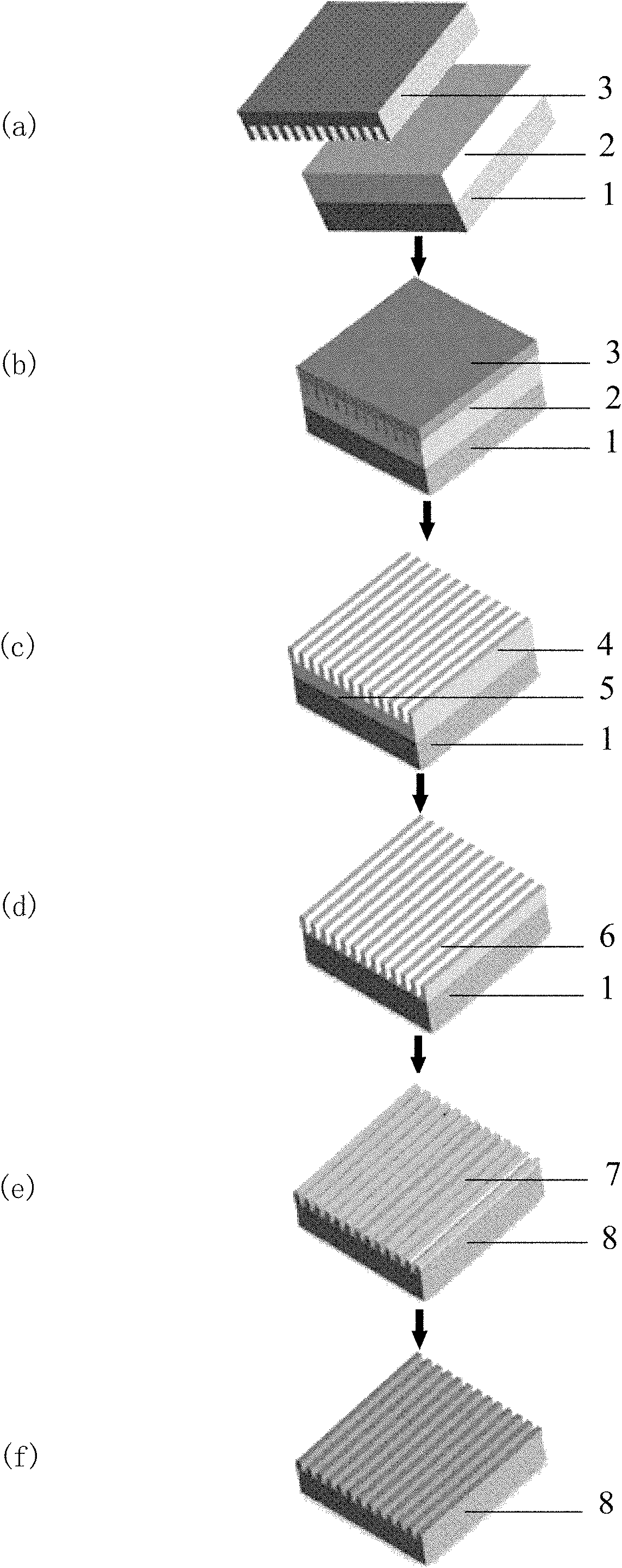

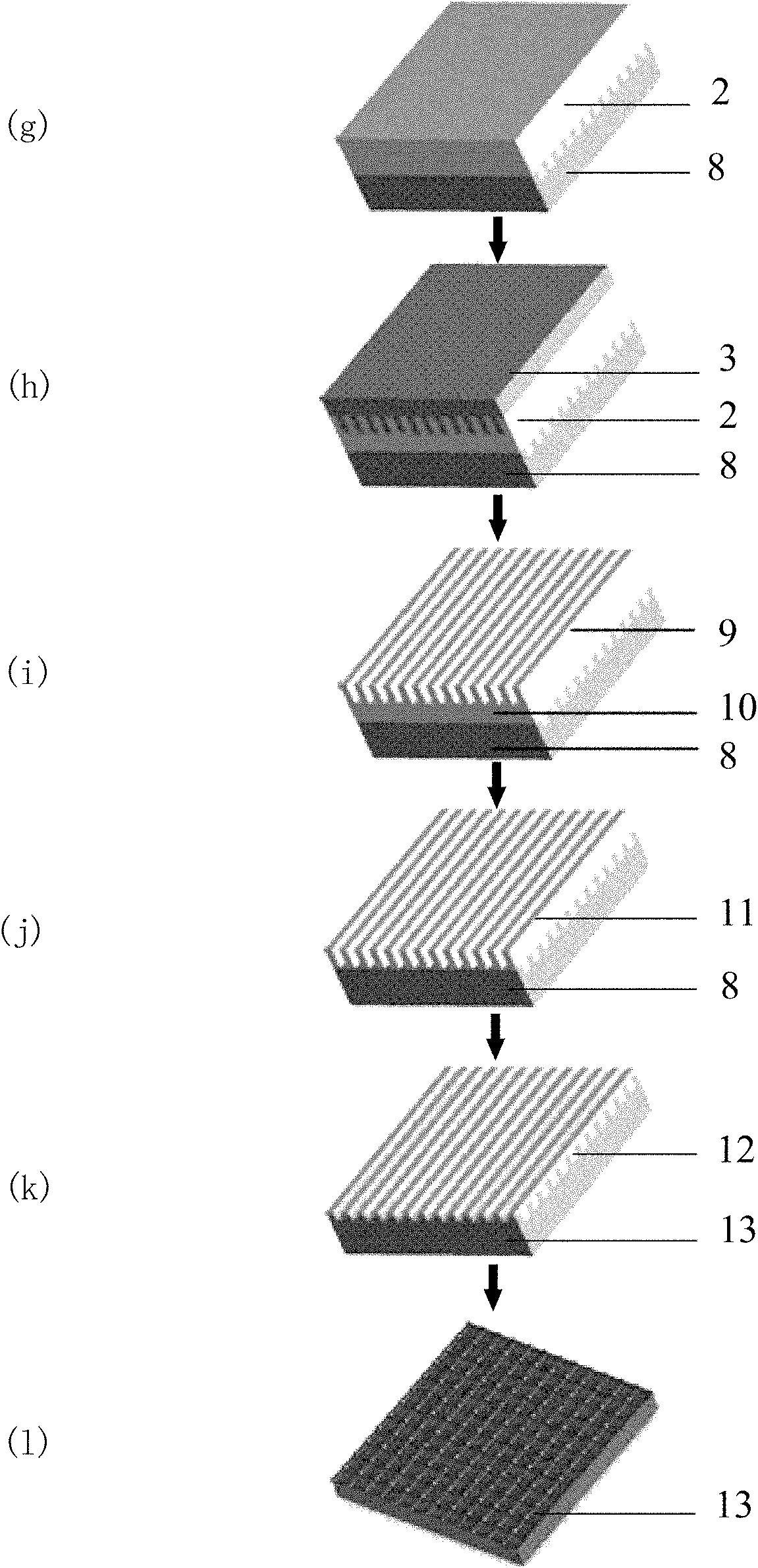

[0031] Embodiment 1: Making a three-dimensional nanogrid structure with Sub-25nm rectangular nano-dots

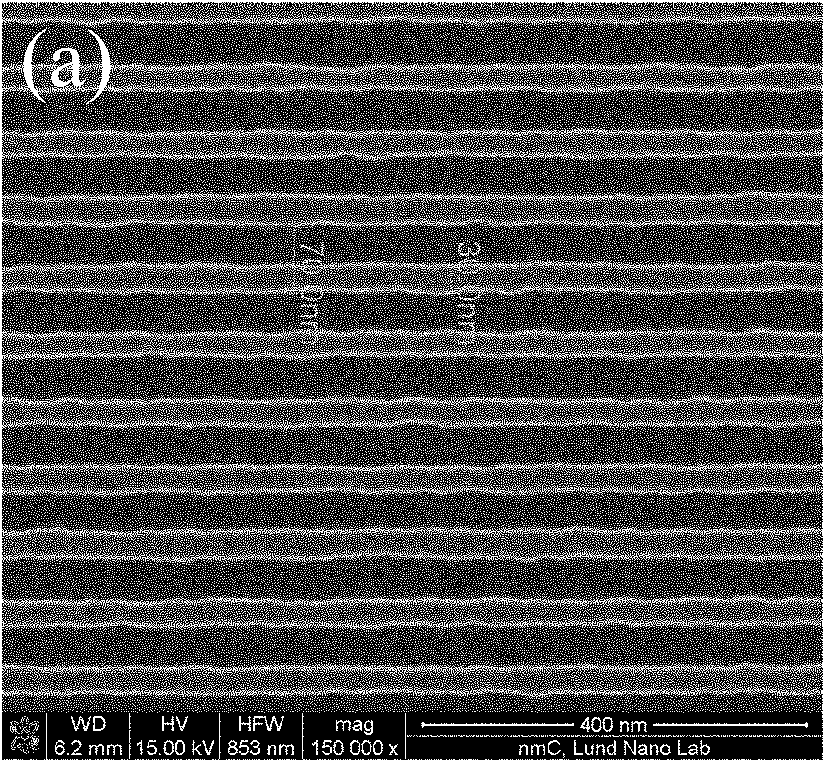

[0032] Prepare the soft template 3 first, on which there is a one-dimensional nano-grating structure, the pattern area is 6mm×10mm, the grating period is 70nm, the line width is 40nm, and the height is 50nm. Figure 2 is the SEM photograph of the master template and the replicated soft template, the soft template material is a fluoropolymer. Take a 2-inch silicon wafer as a substrate 1, clean it, and then spin-coat a thermoplastic UV-curable nano-imprint adhesive 2. The thickness of the embossing glue 2 is between 30-50nm. as attached figure 1 As shown in (b), the soft template was used to imprint on the substrate spin-coated with imprinting glue. The imprinting pressure was 20 bar, the imprinting temperature was 65°C, the imprinting time was 180s, and then exposed to ultraviolet light for 30s. as attached figure 1 As shown in (c), the soft template is separated from the...

Embodiment 2

[0046] Embodiment 2: Making a three-dimensional nanogrid structure with Sub-25nm diamond-shaped nano-dots

[0047] Using the same soft template as in Example 1, the same embossing and etching parameters, by adjusting the angle between the direction of the grating lines on the soft template 3 and the direction of the grating lines on the imprinting substrate 8 in the second imprinting process to be 45° , the line width of the obtained three-dimensional silicon nanogrid structure is 25nm, the period is 70nm, and the nano-dot size at the top of the intersection of the two gratings is sub-25nm. The shapes of the nanogrid structure and the nanodots are rhombuses with an included angle of 45°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com