Reflective stripe, solar assembly using same and preparation method of reflective stripe

A technology of reflective strips and solar cells, which is applied in the field of solar modules, can solve problems such as power loss and inability to use cells, and achieve the effects of avoiding short circuits, good reflectivity, and good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

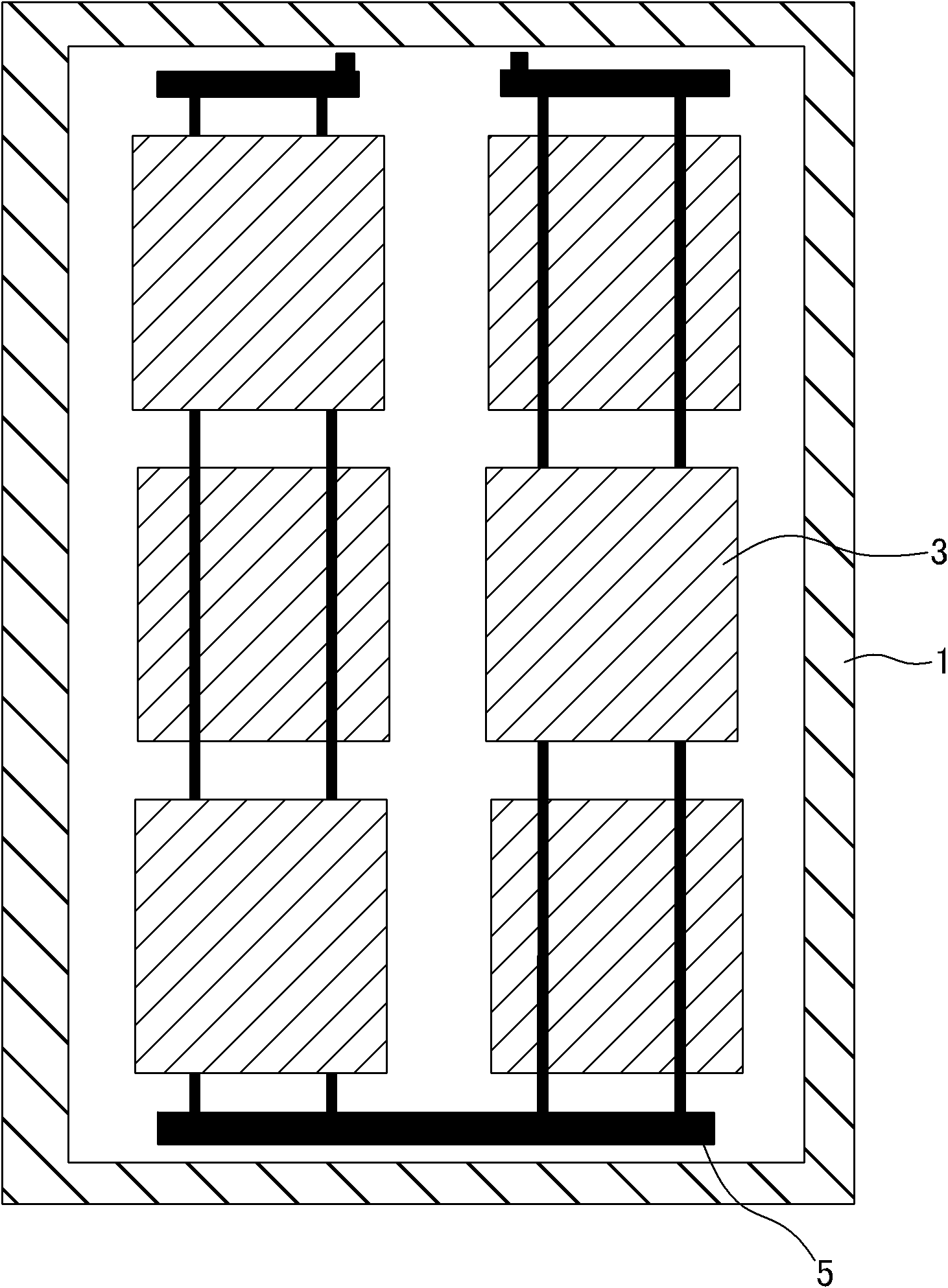

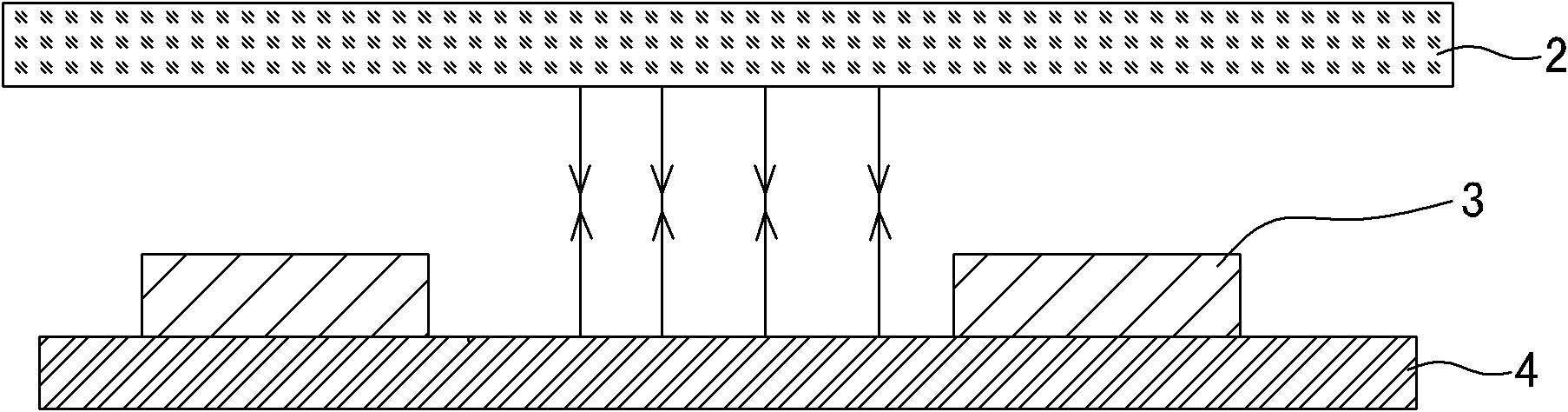

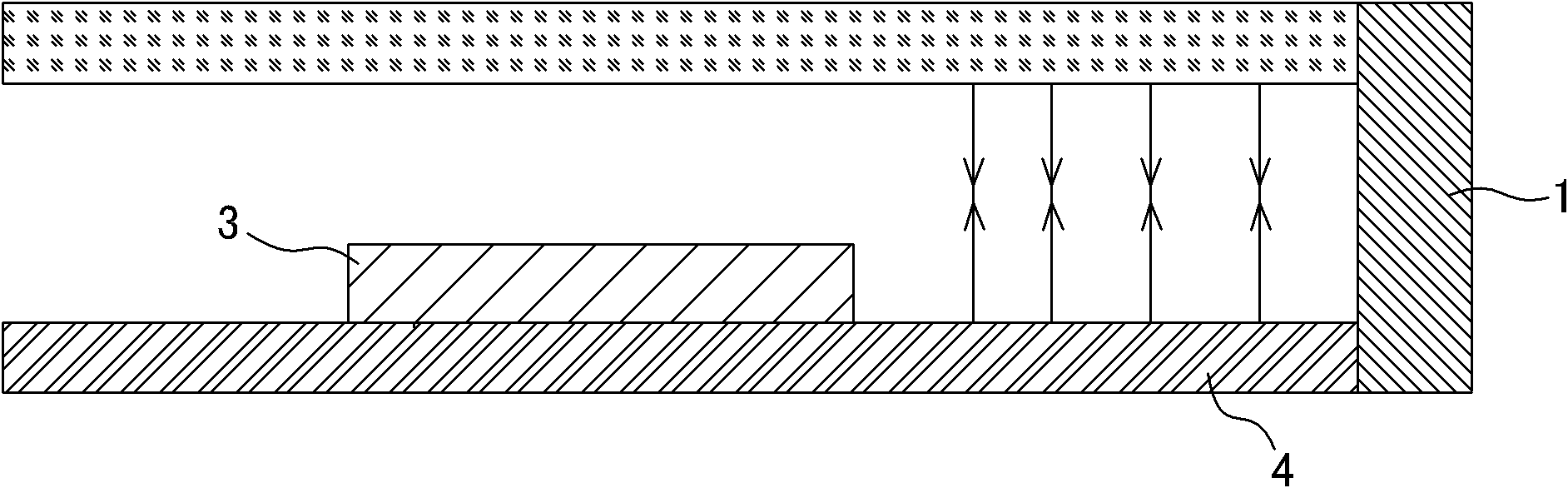

Image

Examples

Embodiment 1

[0050] Both the reflective strips in Embodiment 1 and Implementation 2 have an insulating structure (separation groove 9 and insulating layer 10 ), so as to avoid short circuit caused by electrical connection between adjacent cells when the reflective strip is installed in the gap.

[0051] The processing steps in the preparation method in the implementation one and the embodiment two are partly similar, and it all comprises the following steps:

[0052] Step 1: use glass fiber or PET material to melt into a flat plate shape, heat and remelt again to form the bottom plate 7;

[0053] Step 2: Use precision gears to press the upper surface of the bottom plate 7 to form a reflective structure that reflects sunlight; the reflective structure is a pyramid suede structure, and the specific processing parameters are 1~3mm 2 Press into 5~15 pyramid structures with a base angle of 20~50 degrees within the range;

[0054] Step 3: Using Physical Vapor Deposition (Physical Vapor Depositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com