Polyurethane orange-peel coating

A polyurethane orange and coating technology, which is applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of affecting the appearance of orange-grain coatings, reducing the solid content of construction, and reducing the effect of orange-grain. Good construction performance and improved orange grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

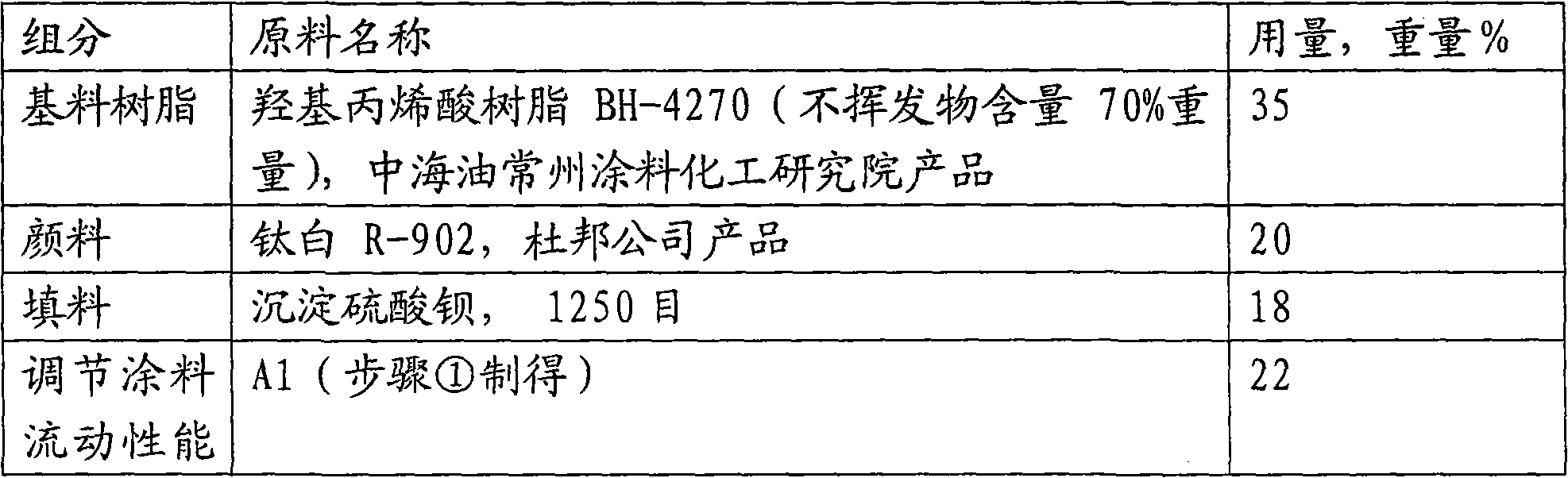

[0016] Embodiment 1 prepares polyurethane orange pattern paint (white)

[0017] ①Preparation of a composition for adjusting the fluidity of the paint (abbreviated as A1)

[0018] In a clean container, add 23.5 g of solvent (toluene: butyl acetate = 1: 1), stir and disperse with a high-speed disperser, slowly add orange grain additive (ZY-62 from Changzhou Zhiyou Mengqi Paint Co., Ltd. Self-forming orange grain additive) 1.5g, stir for 10 minutes, then add 75g of hydroxy acrylic resin (RCR3000-X-60 resin produced by CNOOC Changzhou Coating and Chemical Industry Institute) containing symmetrical diurea groups, stir for 20 minutes, store for later use ;

[0019] ②Preparation of component B

[0020] Component B is composed of the following components, and the amount of each component is as follows by weight percentage: 30-50% of base resin, 5-25% of pigment, 10-20% of filler, 20-30% of the composition for adjusting the fluidity of the paint %, the balance is solvent, and the sp...

Embodiment 2

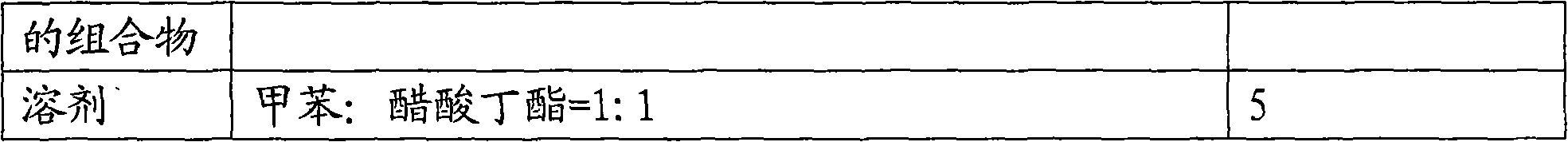

[0029] Embodiment 2 prepares polyurethane orange pattern paint (white)

[0030] ①Preparation of a composition for adjusting the fluidity of the paint (abbreviated as B1)

[0031] In a clean container, add 18 g of solvent (toluene: butyl acetate = 1: 1), stir and disperse with a high-speed disperser, slowly add orange grain additive (L-4630 orange grain aid from Shanghai Deyude Trading Co., Ltd. agent) 2.0g, stirred for 10 minutes, then added 80g of saturated polyester resin (product RCR2001-X-60 resin produced by CNOOC Changzhou Paint Chemical Industry Institute) containing symmetrical diurea groups, stirred for 20min, preserved, and set aside;

[0032] ②Preparation of component B

[0033] The specific formula of component B is shown in Table 2, and the preparation steps are the same as in Example 1.

[0034] Table 2

[0035]

[0036] ③ Prepare group A

[0037] Using Bayer's product N-75 (HDI biuret)

[0038] ④Preparation of polyurethane orange coating

[0039] Accord...

Embodiment 3

[0040] Embodiment 3 prepares polyurethane orange pattern paint (yellow)

[0041] ①Preparation of a composition for adjusting the fluidity of the paint (abbreviated as A2)

[0042]In a clean container, add 23.5 g of solvent (toluene: butyl acetate = 1: 1), stir and disperse with a high-speed disperser, slowly add orange grain additive (ZY-62 from Changzhou Zhiyou Mengqi Paint Co., Ltd. Self-forming orange grain auxiliary agent) 1.5g, stirred for 10 minutes, then added 75g of hydroxyacrylate resin (product 81198 resin produced by Newpace Co., Ltd.) containing symmetrical diuretyl groups, stirred for 20min, preserved, and set aside;

[0043] ②Preparation of component B

[0044] The specific formula of component B is shown in Table 3, and the preparation steps are the same as in Example 1.

[0045] table 3

[0046]

[0047] ③ Prepare group A

[0048] Using Bayer's product N-3390 (HDT trimer)

[0049] ④Preparation of polyurethane orange coating

[0050] According to the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com