135 steel-level drill rod connector and heat treatment process thereof

A technology of drill pipe joints and steel grades, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems that cannot meet the performance requirements of 135 steel grade drill pipe joints, and achieve the effect of stable mechanical properties and wide process range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

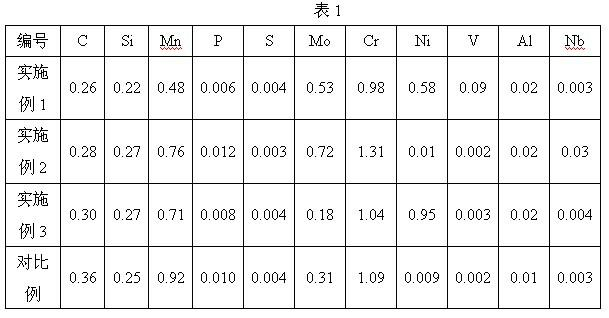

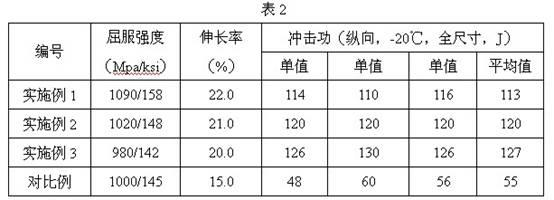

[0012] According to the chemical composition requirements of the present invention, three heats of steel were refined. Then continuous casting and rolling into round steel that meets the requirements. Cut the round steel to a certain length and forge it into NC50 joint blank. Take 10 joints from each of the three batches of rough machining and 10 joints of the same specification 37CrMnMo, and heat treat them in batches. After heat treatment, samples are taken for chemical analysis, tensile and impact tests.

[0013] The heat treatment process of the present invention is as follows: raise the roughly machined joint blank from room temperature to 920-960°C in 80-100 minutes, keep it warm for 0.5-1.5 hours, put it into a 30-50°C oil-based quenching medium, and fully Cool it, then raise it from room temperature to 550-620°C in 50-70 minutes, keep it warm for about 1.5-2.5 hours, and then take it out of the oven.

[0014] The mechanical properties (the average value of each 10 jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com