Self-cleaning microwave antenna with resistance to high temperature and corrosion

A microwave antenna and self-cleaning technology, applied in waveguide devices, liquid/fluid solid measurement, engine lubrication, etc., to achieve the effect of large volume, fast cooling, and good heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

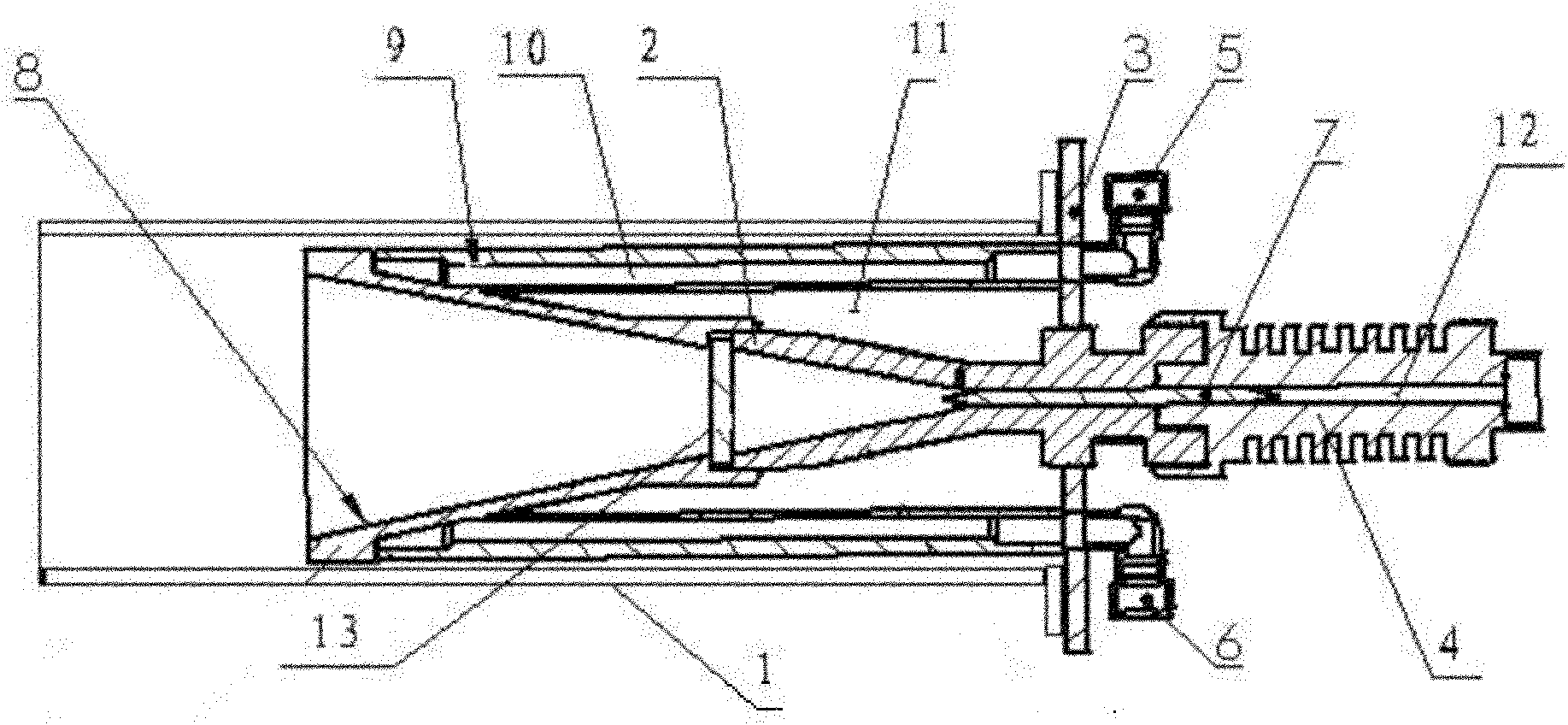

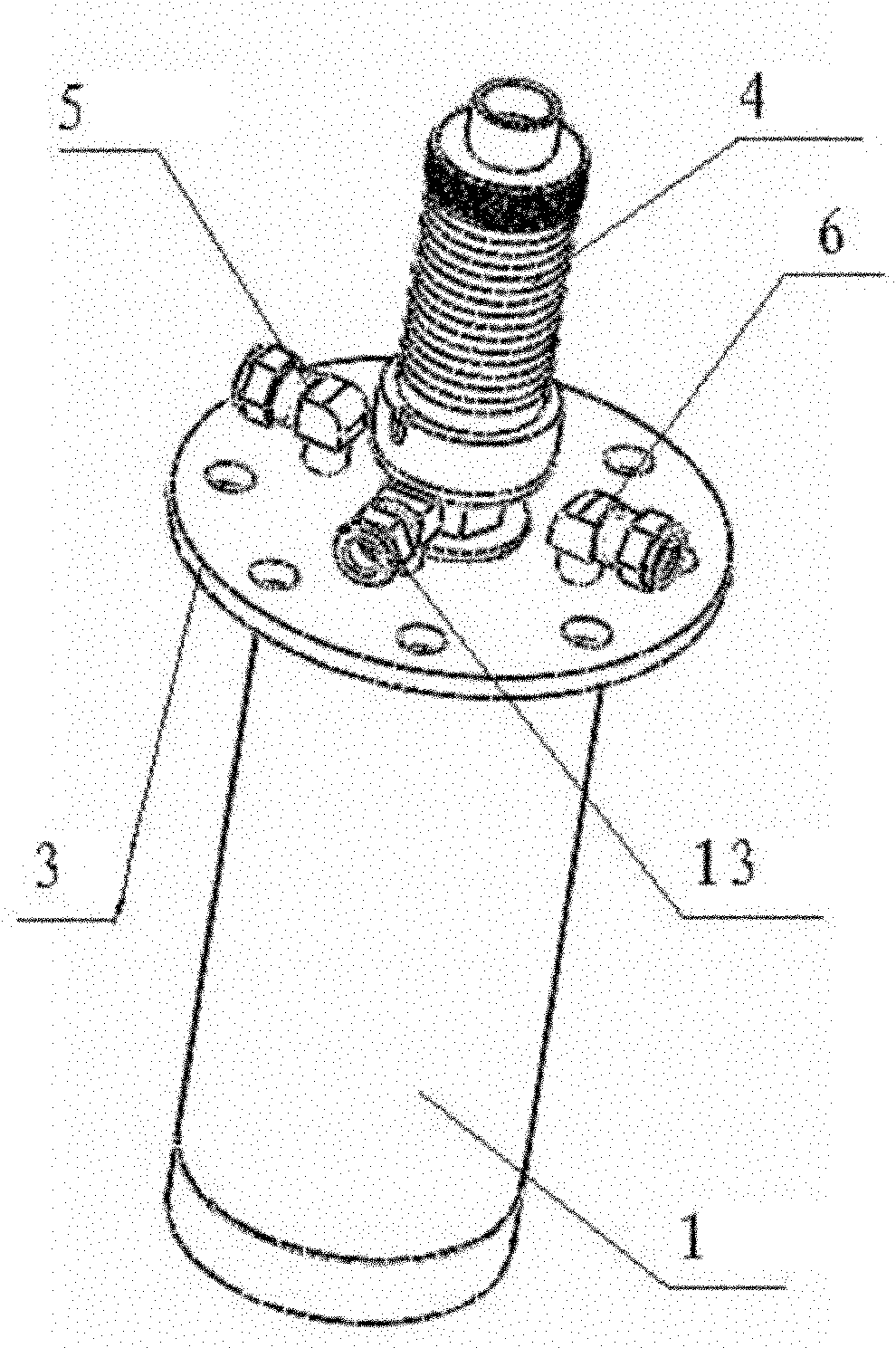

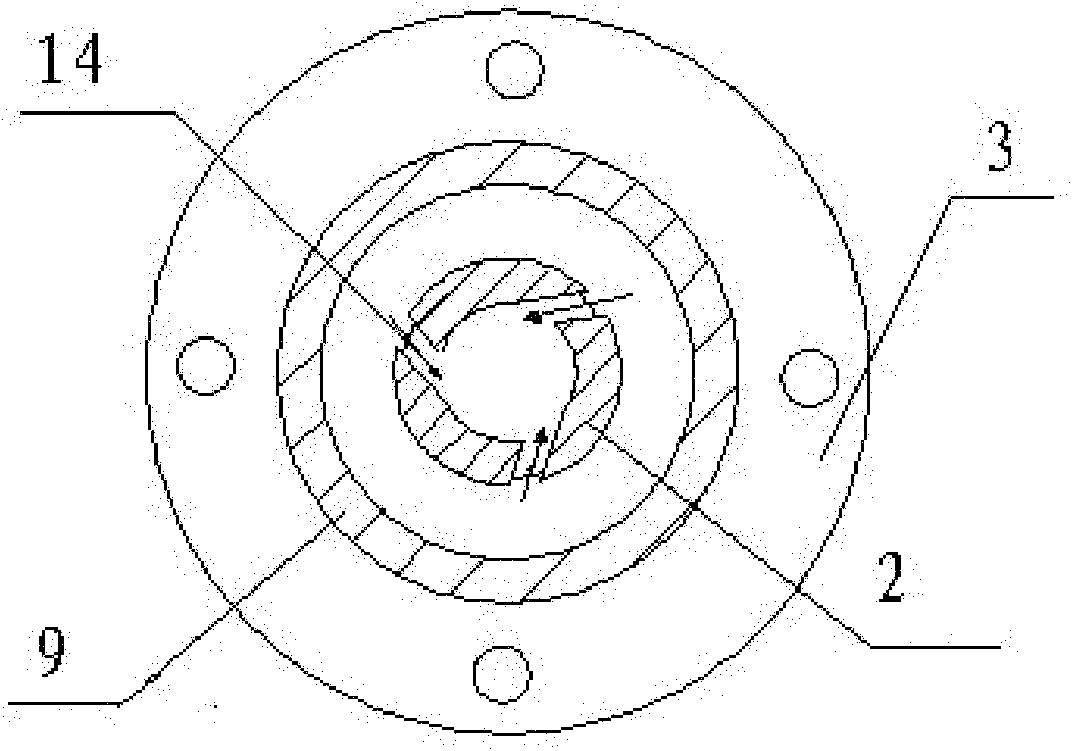

[0029] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0030] Such as Figure 1-4 As shown, the present invention is a high-temperature-resistant self-cleaning anti-corrosion microwave antenna, which includes an outer sleeve 1, an antenna inner cover 2, a flange piece 3, a heat sink 4, a water inlet joint 5, a water outlet joint 6, and a PTFE antenna rod 7. High temperature protective coating 8, water cooling cover 9, water cooling pipe 10, air cooling cavity 11, microwave channel 12, wave transparent material plate 13, air inlet joint 14, air inlet 15, flow detection device 16, and gas flow Count 17.

[0031]The upper end of the outer sleeve 1 is welded with the flange piece 3; the antenna inner cover 2 is placed in the outer sleeve 1, and the upper end is threaded with the flange piece 3; the inner surface of the antenna inner cover 2 is coated with a high-temperature protective coating 8, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com