Electromagnetic wave absorbing material

A wave-absorbing material and electromagnetic wave technology, applied in the direction of layered products, chemical instruments and methods, metal layered products, etc., can solve the problems of increasing the thickness of the absorber, harsh requirements for materials, and limitations in magnetic permeability, etc., to achieve the expansion of absorbing Wave frequency band, low cost, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

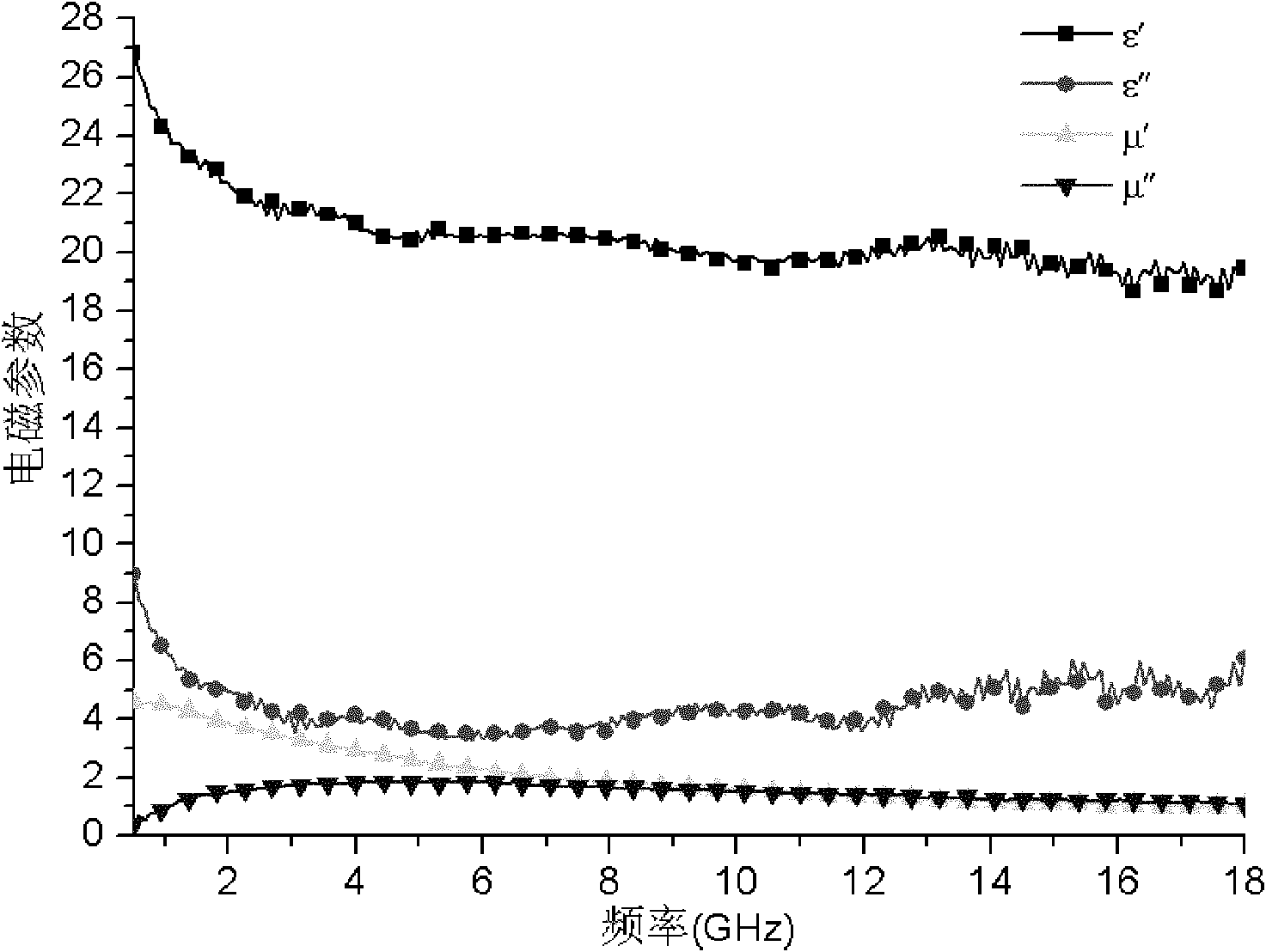

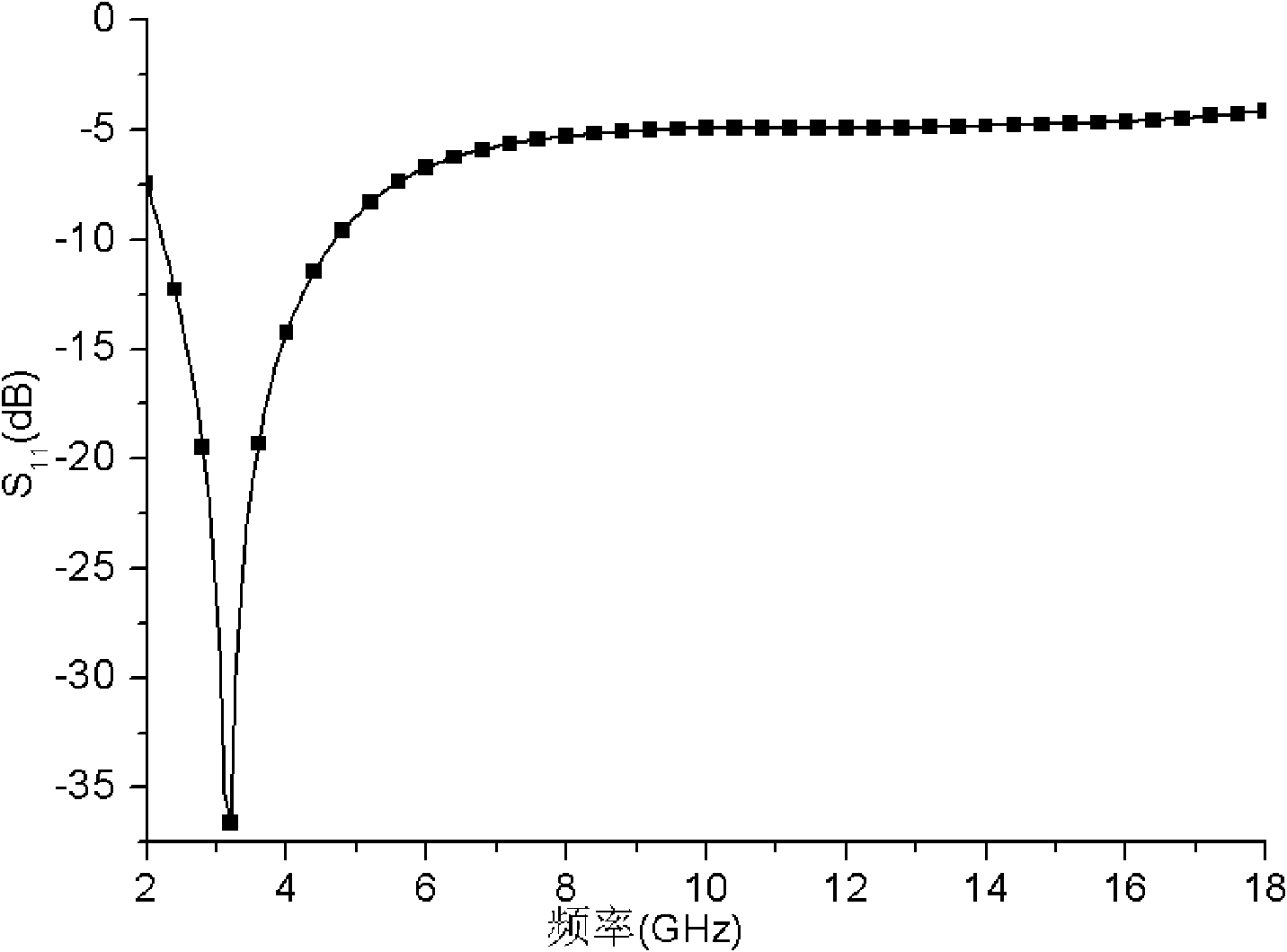

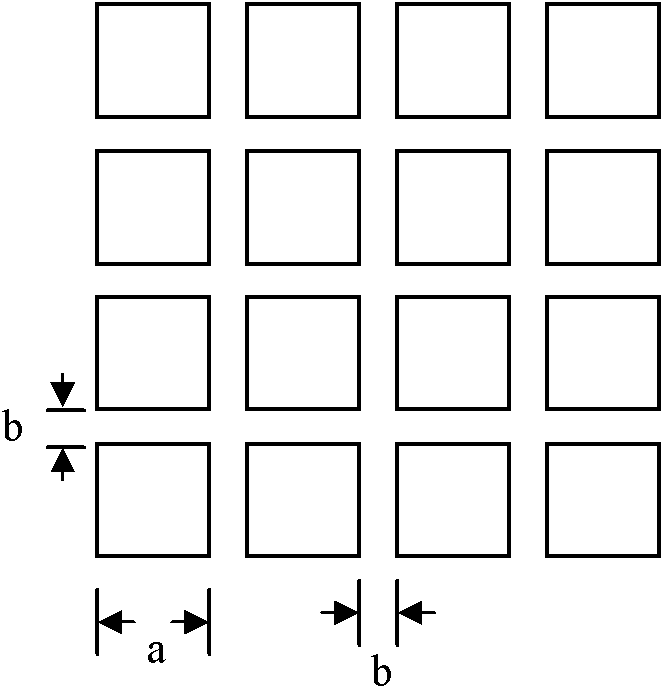

[0016] An electromagnetic wave-absorbing structure is formed by embedding periodic aluminum foil patterns in an existing wave-absorbing rubber plate. Aluminum foil unit size a=7mm, aluminum foil unit spacing b=3mm.

[0017] The electromagnetic absorber designed by the above method, in the case of vertical incidence of TE or TM waves, its 9.5dB attenuation frequency band is below 2GHz to 7.2GHz (the lowest frequency band that can be tested by this experimental test equipment is 2GHz), and the bandwidth is greater than 5.2 GHz. However, for the 2.5mm thick wave-absorbing rubber sheet not embedded with periodic aluminum foil, the 9.5dB attenuation frequency range is 2.2GHz to 4.8GHz, and the bandwidth is 2.6GHz. In contrast, the absorbing structure more than doubles the bandwidth. The reason is the generation of double resonance: the first resonance between the aluminum foil and the metal film of the test equipment, and the second resonance by the structure of the aluminum foil...

Embodiment 2

[0019] An electromagnetic wave-absorbing structure is formed by embedding periodic aluminum foil in the existing wave-absorbing rubber plate. The size of the aluminum foil unit is a=5mm, and the distance between the aluminum foils is 5mm.

[0020] The electromagnetic wave absorber designed in the above manner has a 9.5dB attenuation frequency range of below 2GHz to 5.04GHz and a bandwidth greater than 3.04GHz under the condition of vertical incidence of TE or TM waves. Compared with the 2.5mm-thick wave-absorbing rubber sheet without embedding periodicity, its bandwidth has also been expanded, but the effect is not as good as that of Embodiment 1. The main reason is that the aluminum foil unit becomes smaller, the resonant frequency moves to high frequency, and the second resonant frequency is much higher than the absorption peak of the rubber sheet, which makes the high frequency effect slightly worse.

Embodiment 3

[0022] An electromagnetic wave-absorbing structure is formed by embedding periodic aluminum foil in the existing wave-absorbing rubber plate. The size of the aluminum foil unit is a=9mm, and the distance between the aluminum foils is 1mm.

[0023] The electromagnetic absorber designed in the above manner has a 9.5dB attenuation frequency band of 5.52GHz to 8.48GHz and a bandwidth of 3.96GHz in the case of vertical incidence of TE or TM waves. Compared with the 2.5mm thick wave-absorbing rubber sheet that is not embedded periodically, the wave-absorbing frequency band shifts to high frequency, failing to achieve the purpose of expanding the bandwidth. The main reason is that the aluminum foil unit becomes larger, and the resonant frequency moves to the low frequency. The resonant frequency is far lower than the absorption peak of the rubber sheet, so the low frequency effect is slightly worse.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com