System and method for treating organic wastewater

A technology for organic wastewater and treatment systems, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of the loss of balanced water quality and quantity in the regulating tank, and the failure of the primary sedimentation tank to treat Effects and other issues, to achieve the effect of reducing the amount of chemicals used, reducing investment costs, and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

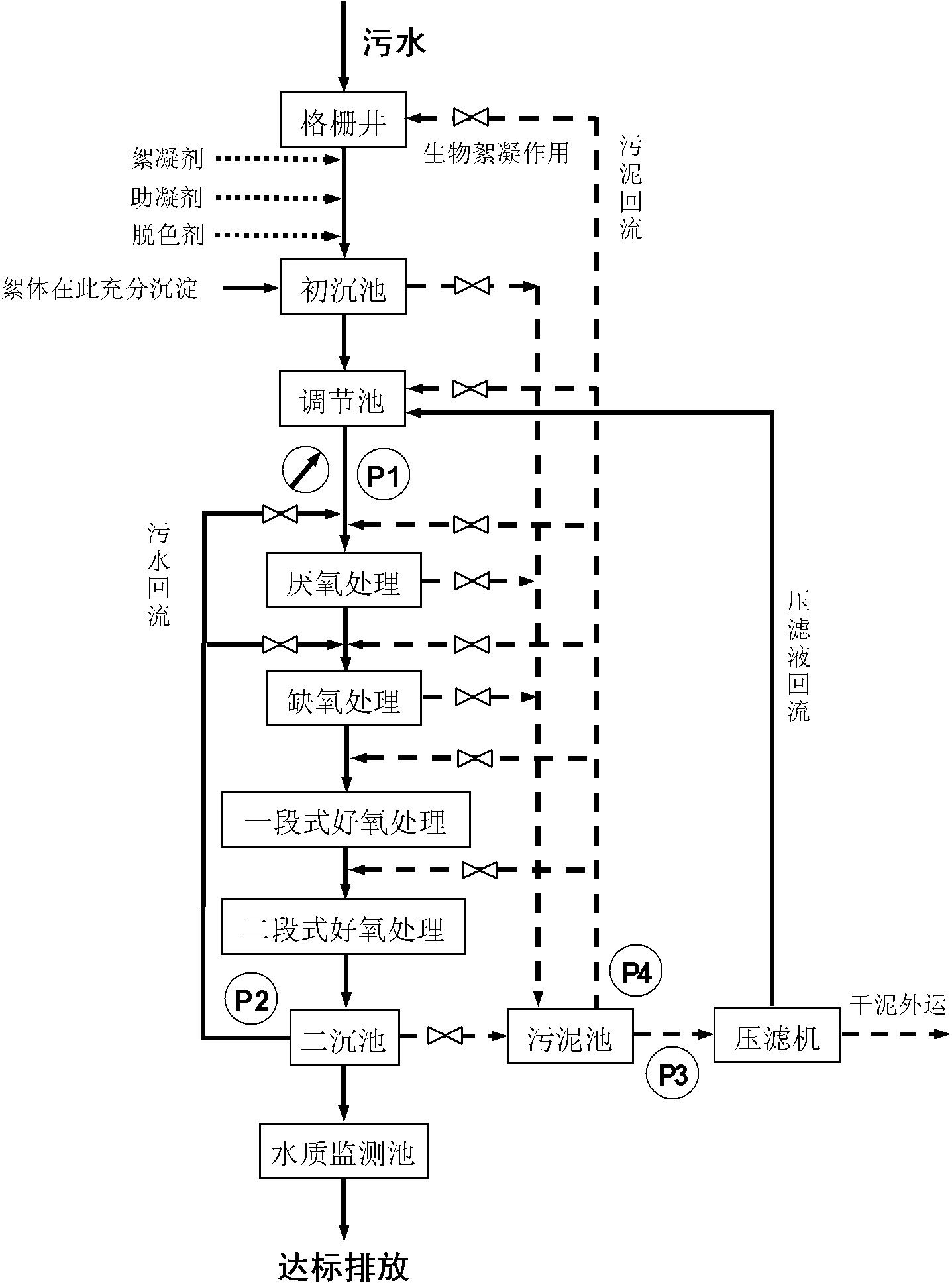

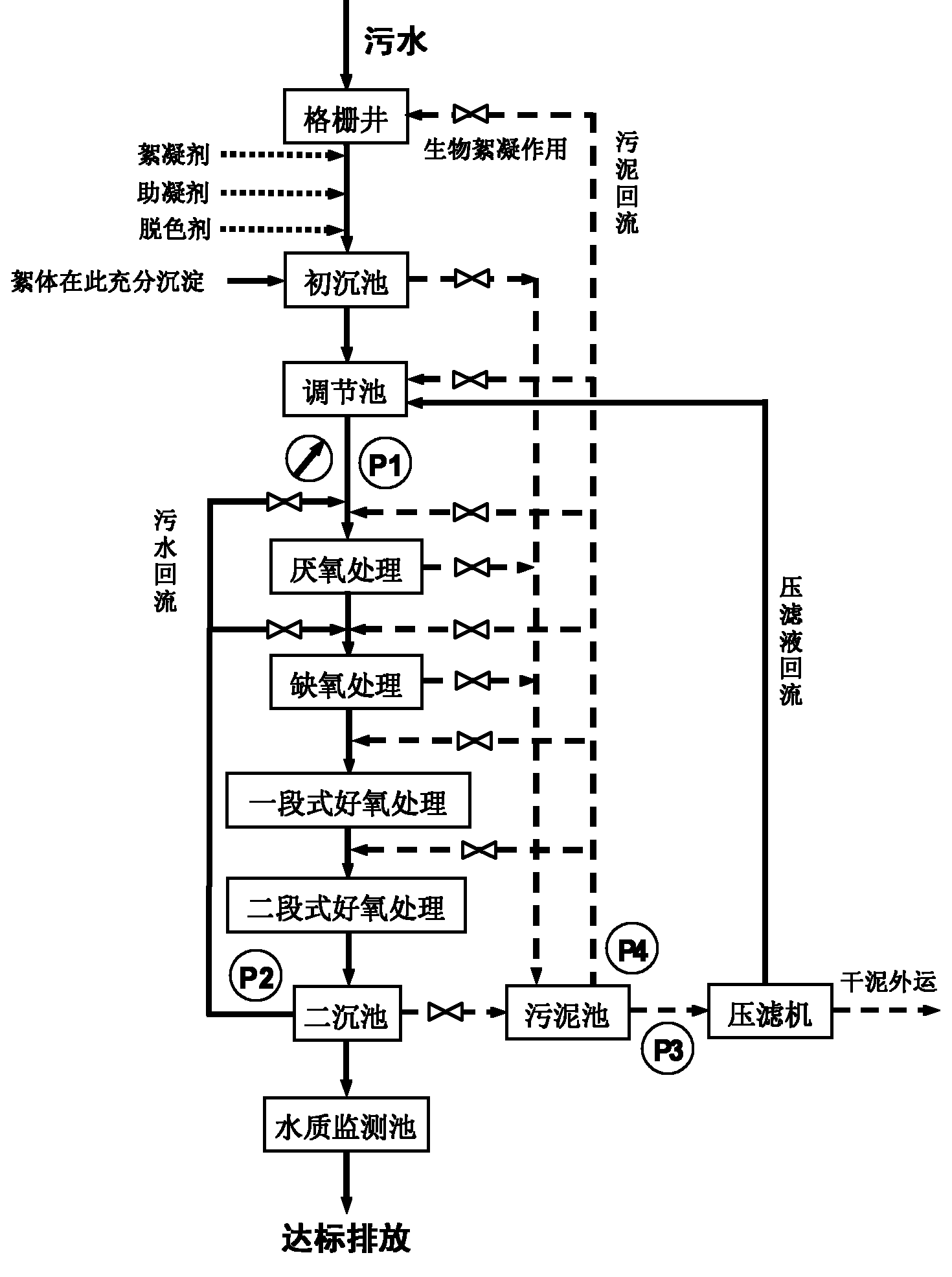

[0028] Such as figure 1 As shown, a treatment system for organic wastewater, the system includes grid wells, primary sedimentation tanks, regulating tanks, anaerobic treatment devices, anoxic treatment devices, and aerobic treatment devices connected by pipelines in sequence according to the flow of organic wastewater , secondary settling tank, sludge tank and water quality monitoring tank, the sludge outlet of the primary settling tank, anaerobic treatment device and anoxic treatment device are connected through the sludge pipeline and the sludge inlet of the sludge tank, and the sludge in the secondary settling tank The outlet is respectively connected to the grid well or the sludge inlet of the adjustment tank through the sludge return pipeline, and the sludge return outlet of the sludge tank is respectively connected to the grid well, the adjustment tank, the anaerobic treatment device, and the anoxic treatment unit through the sludge return pipeline. The device is connect...

Embodiment 2

[0030] Such as figure 1 Shown, a kind of treatment method of organic waste water comprises the following steps successively:

[0031] According to the sewage water quality and effluent requirements, determine the amount of flocculant, coagulant aid or decolorant, and add flocculant, coagulant aid or decolorant to the sewage step;

[0032] Primary sedimentation tank treatment steps; determine the hydraulic load of the primary sedimentation tank according to the sewage water quality.

[0033] conditioning pool processing steps;

[0034] Anaerobic anoxic treatment step;

[0035] Anoxic treatment step;

[0036] One-stage aerobic treatment and two-stage aerobic treatment steps;

[0037] Secondary settling tank treatment steps;

[0038] The sludge produced in the treatment step of the secondary settling tank enters the sludge tank, and the sewage produced in the treatment step of the secondary settling tank is respectively returned to the anaerobic treatment device and the anox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com