A kind of iron source sapo-34 catalyst with low temperature scr activity and its preparation method and application

A SAPO-34 and catalyst technology, which is applied in the field of low-temperature SCR active iron source SAPO-34 catalyst and its preparation, can solve the problem of undiscussed synthesis and low-temperature denitration performance, controllable synthesis of Cu-doped FeSAPO-34 and low-temperature SCR Activity and other issues, to achieve the effects of not easy loss, simple preparation process, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

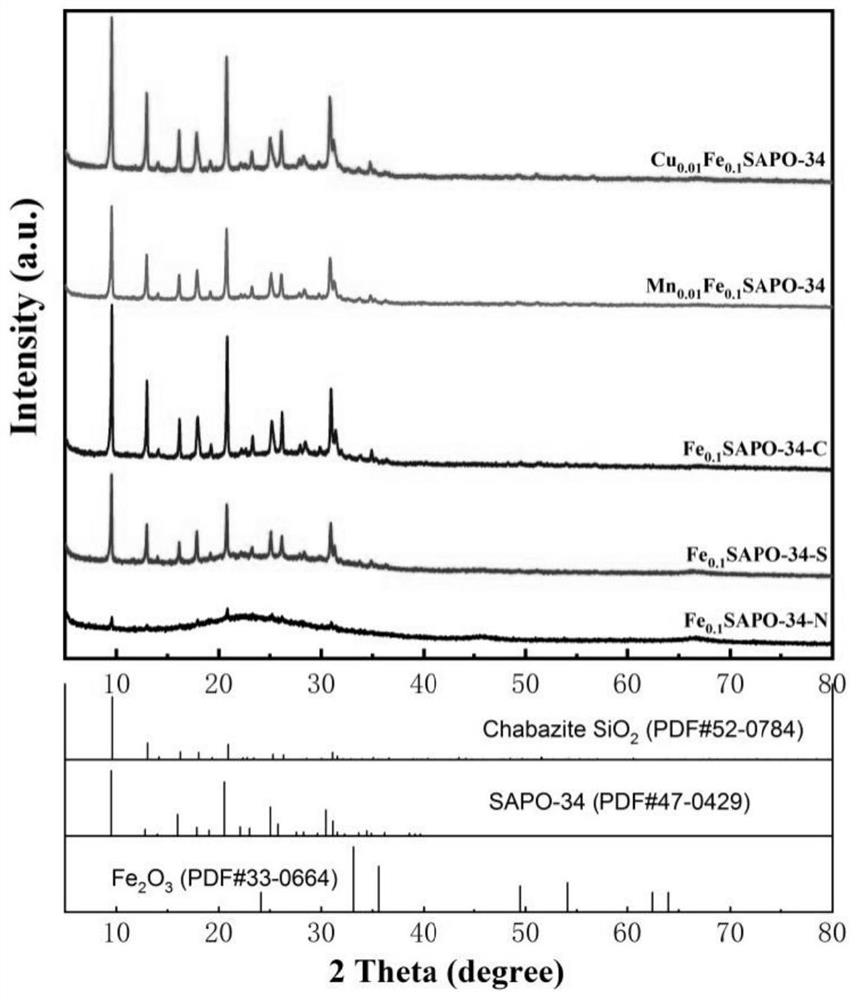

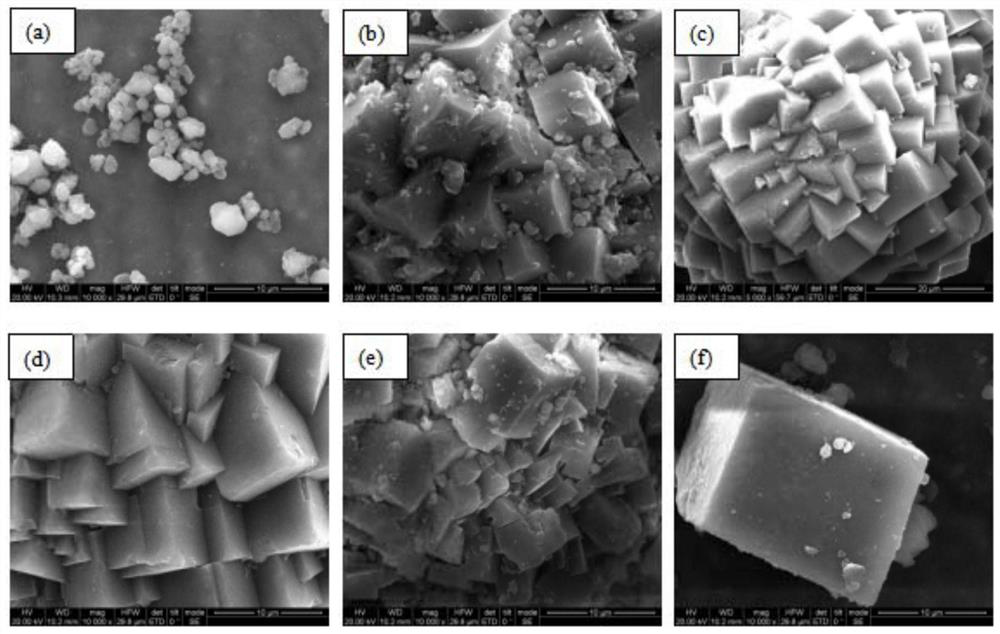

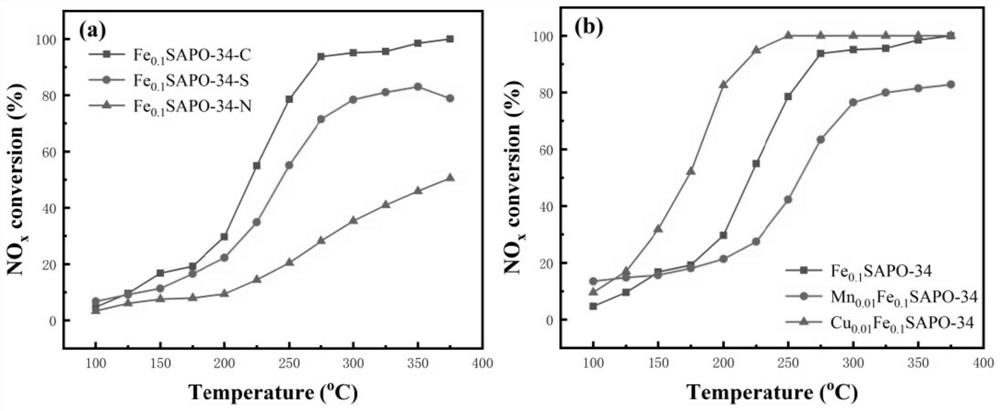

[0039] Embodiment 1: FeSAPO-34-C catalyst

[0040] The iron source SAPO-34-C catalyst with low-temperature SCR activity provided by this embodiment, its preparation raw materials include pseudoboehmite, orthophosphoric acid, water, silica sol, ferrous acetate and tetraethylenepentamine; Composition meter, AlOOH, H 3 PO 4 、H 2 O, SiO 2 , Fe and tetraethylenepentamine molar ratio is 1:0.62:40:0.25:0.1:0.27.

[0041] The specific preparation method is: fully mix and stir about 7.15g orthophosphoric acid and a certain amount of deionized water for 0.5h, then add about 7.50g of pseudo-boehmite, and fully mix and stir for 0.5h, and then add a certain amount of Silica sol, after being mixed evenly, it will be A mixed solution. Then first configure the B mixed solution, a certain amount of 20wt% ferrous acetate solution and 1.893g tetraethylenepentamine are stirred for 2 hours to form Fe-TEPA (B mixed solution), and then slowly add the B mixed solution to the A which has been in ...

Embodiment 2

[0042] Embodiment 2: FeSAPO-34-S catalyst

[0043] Adopt ferrous sulfate as iron source, prepare FeSAPO-34-S molecular sieve catalyst Fe according to the method in embodiment 1 0.1 SAPO-34-S.

Embodiment 3

[0044] Embodiment 3: FeSAPO-34-N catalyst

[0045] Adopt ferric nitrate nonahydrate as iron source, prepare Fe SAPO-34-N molecular sieve catalyst Fe according to the method in embodiment 1 0.1 SAPO-34-N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com