Polypropylene composite material with fire retardance and toughening performance

A composite material, polypropylene technology, applied in the field of polypropylene composite materials, can solve the problems of difficult large-scale application, large amount of addition, poor compatibility, etc., achieve easy industrial production, improve impact strength, material performance stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-26

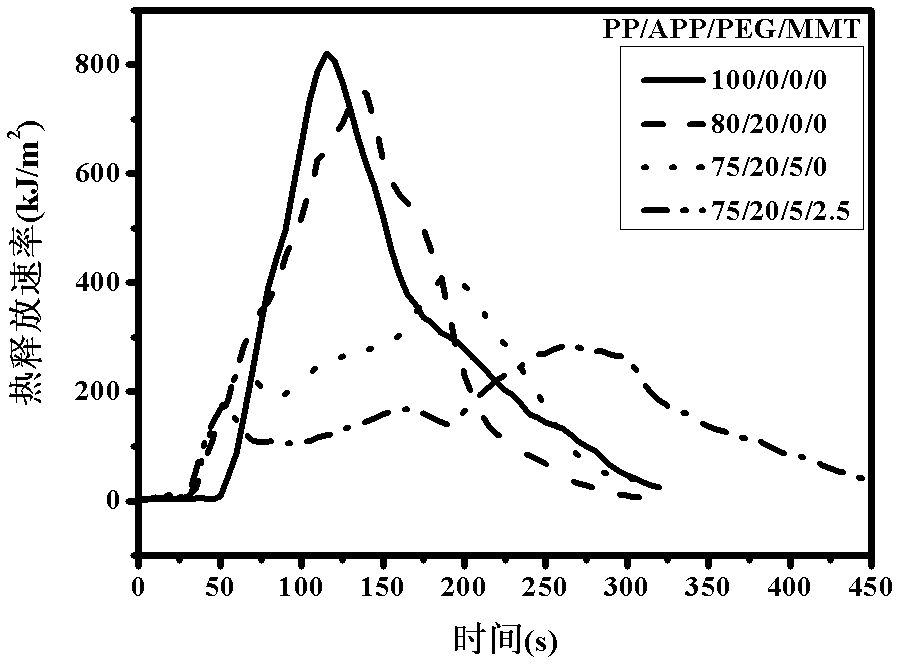

[0027] Mix iPP, APP, PEO and MMT according to the ratio of each material given in the attached table, put them into a twin-screw extruder for melt blending and extrusion, and set the temperature of each section of the extruder to 110, 160, 195, 195, 195, 195 and 190°C with a screw speed of 120rpm. The extruded strips are cooled by water and then drawn to a pelletizer for pelletizing, and the pellets are dried in a vacuum oven at 60°C for 6 hours. Wherein the number average molecular weight of the PEO that embodiment 1~11 is used is 20000; The number average molecular weight of the PEO that embodiment 12~16 is used is 100000; The number average molecular weight of the PEO that embodiment 17~21 is used is 200000; Embodiment 22~ The number average molecular weight of the PEO used in 26 is 300,000, and the test results of vertical combustion performance, limiting oxygen index (LOI), tensile strength and notched Izod impact strength of the composite materials obtained in each examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com