Potential difference circulating bioreactor

A bioreactor, circulating technology, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instruments, etc. Advanced problems, to achieve good mixed ventilation effect, enhance ventilation effect, and increase the effect of exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

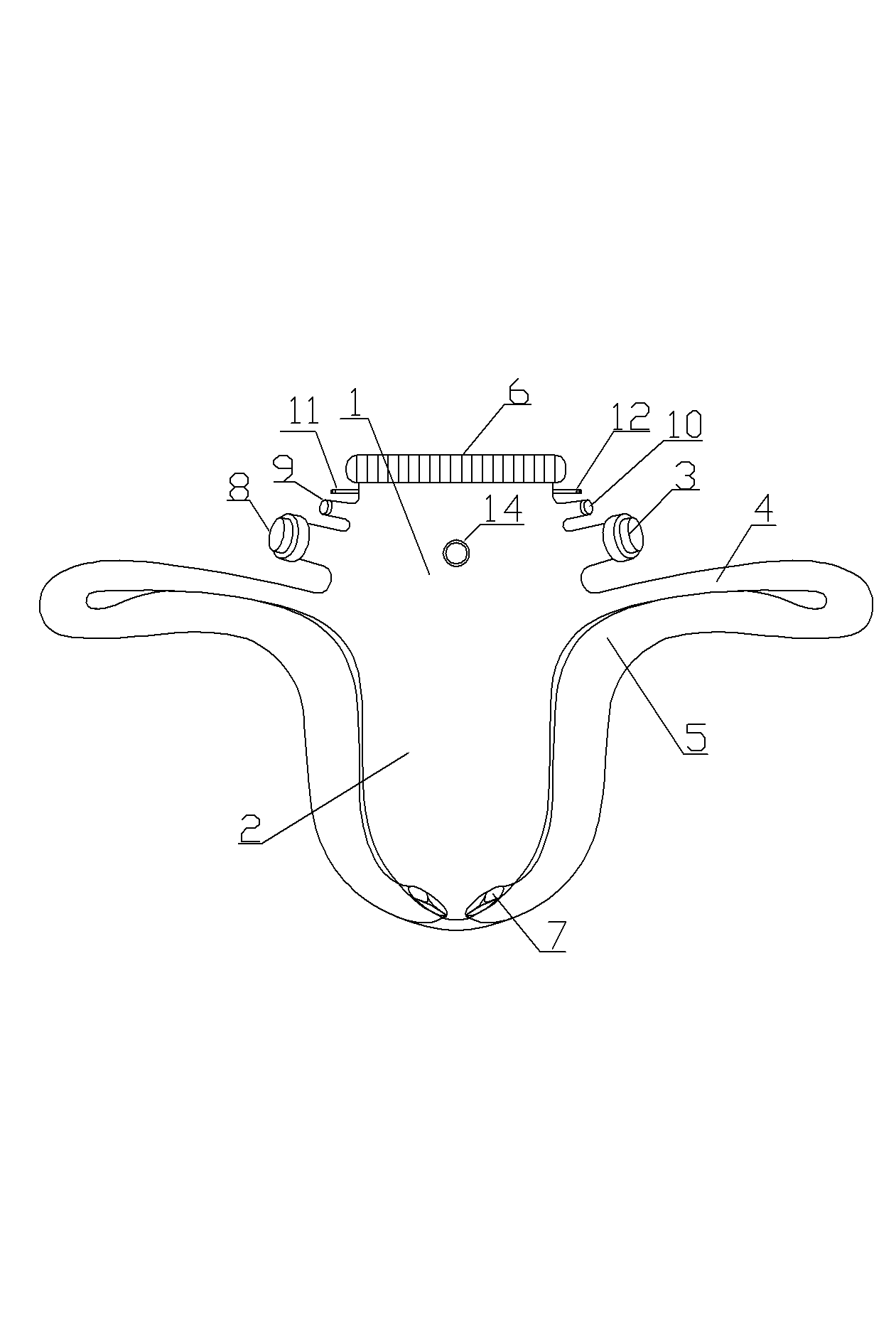

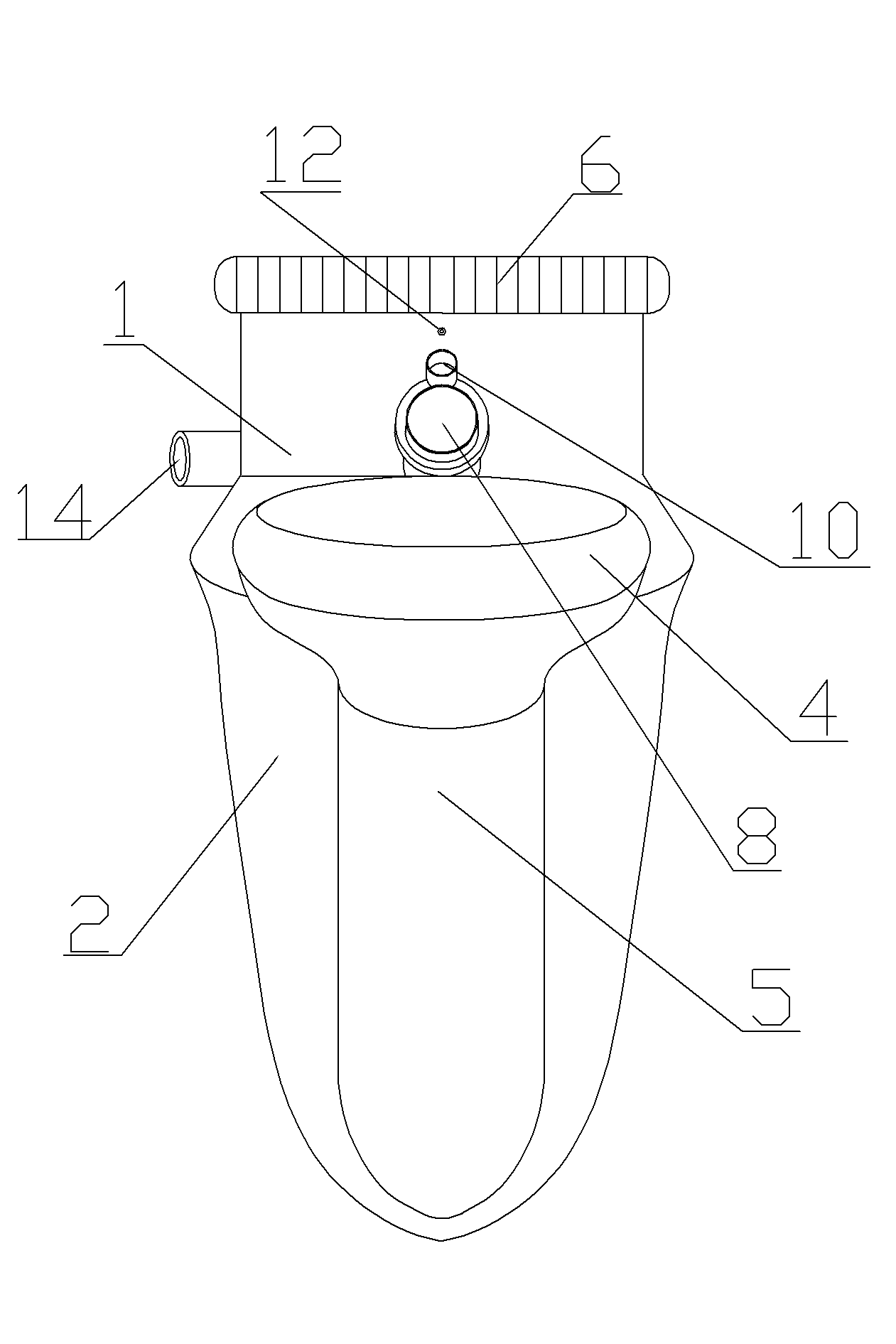

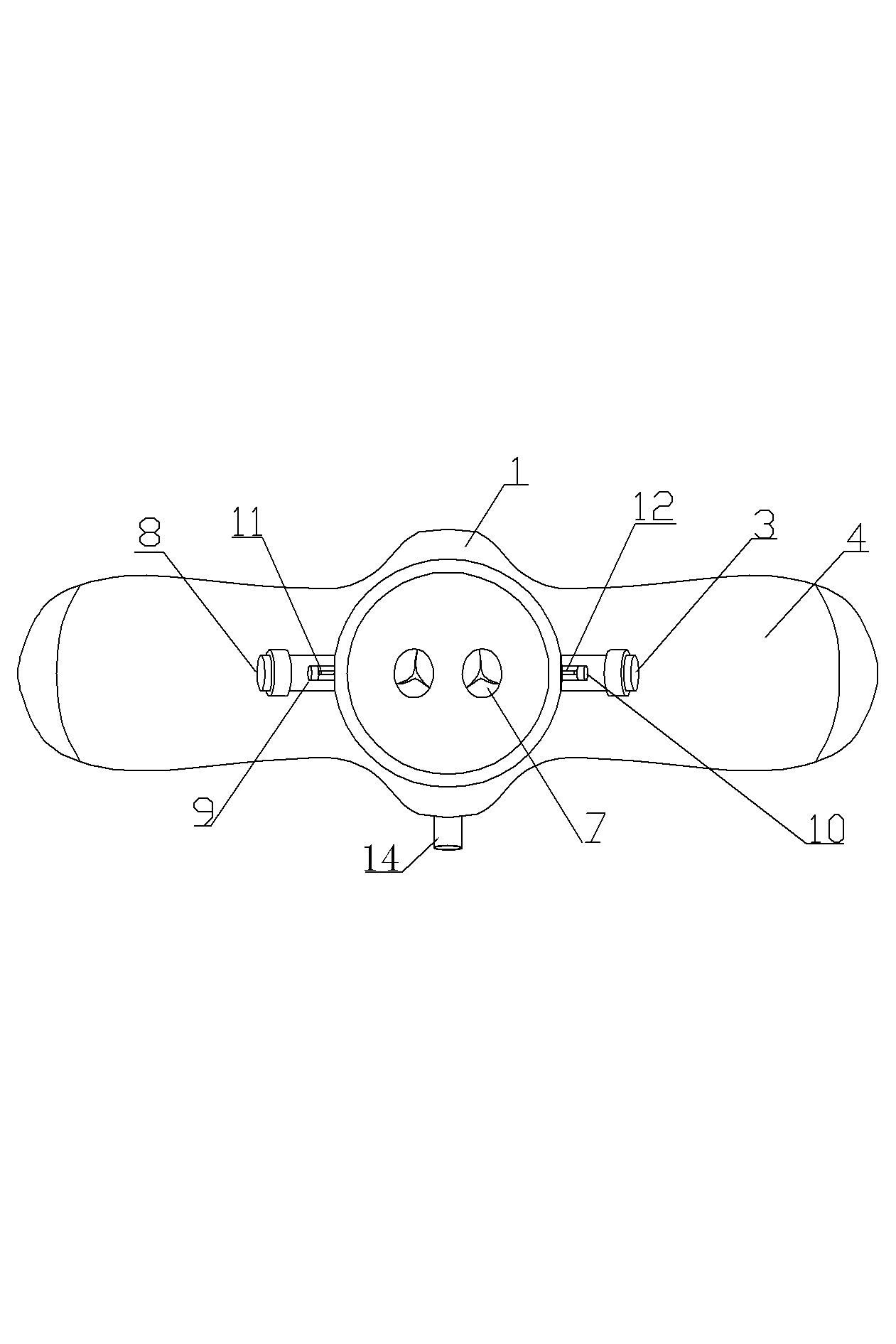

[0031] A kind of embodiment 1 of potential difference circulation type bioreactor, in Figure 1~7 Among them, the reactor includes a container body, and the inner cavity of the container body is divided into upper and lower parts, the upper part is a gas chamber 1, and the lower part is a liquid chamber 2. The side wall of the container body has two side wing channel structures 4 extending to both sides. The side wing channel structure 4 is located at the adjoining place of the air holding chamber and the liquid containing room. The side wing channel structure 4 has two ports inside and outside. The inner port of the channel structure 4 communicates with the inner cavity of the container body, the outer port of the flank channel structure 4 communicates with the upper port of the circulation pipe 5, and the upper section of the circulation pipe 5 is arranged close to the bottom of the flank channel structure 4, and the circulation pipe 5 The upper end of the upper end extends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com