Treatment method of itaconic acid waste residue

A treatment method, itaconic acid technology, is applied in the direction of waste fuel, fermentation, etc., to achieve the effects of improving utilization rate, realizing recycling, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

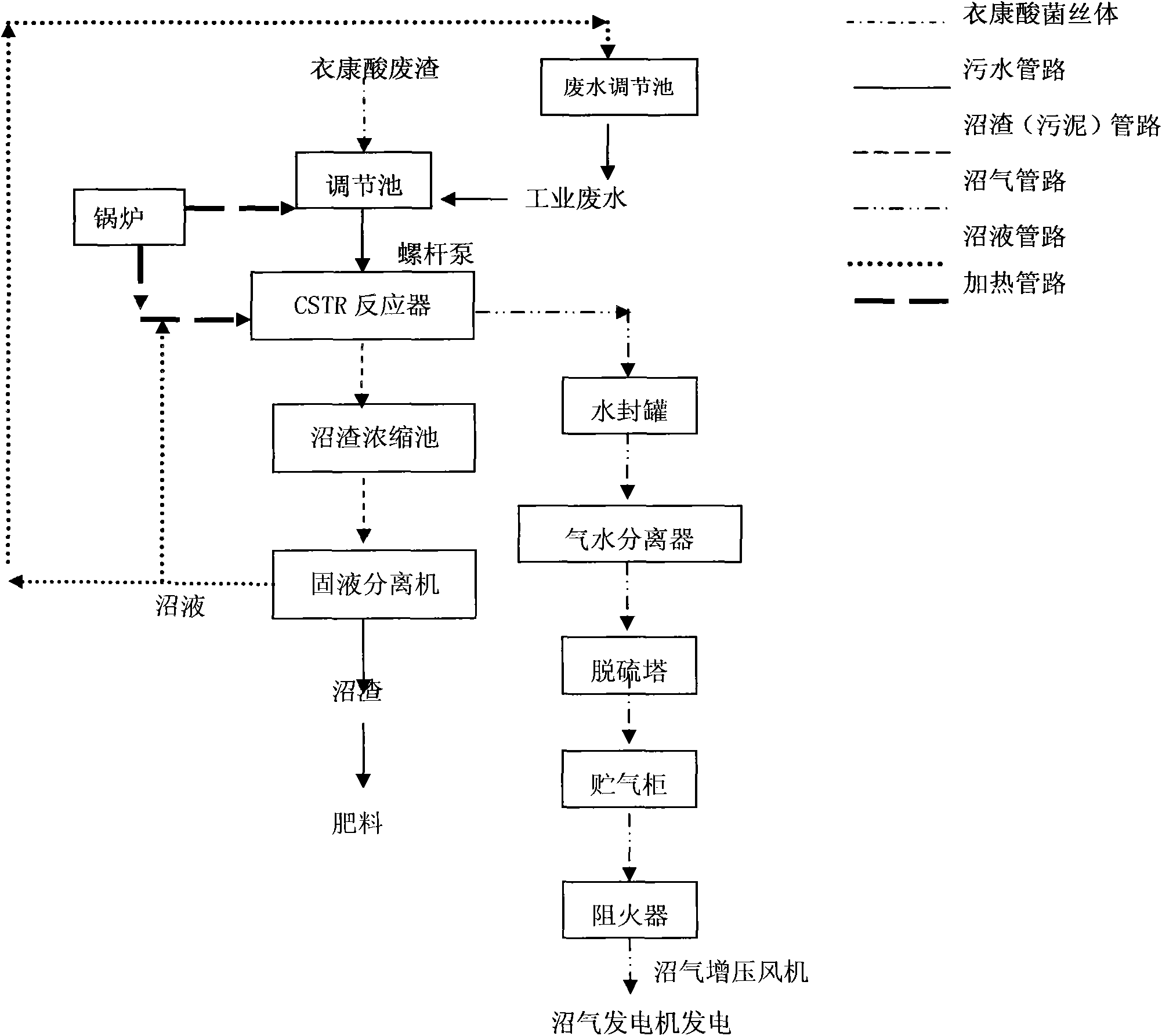

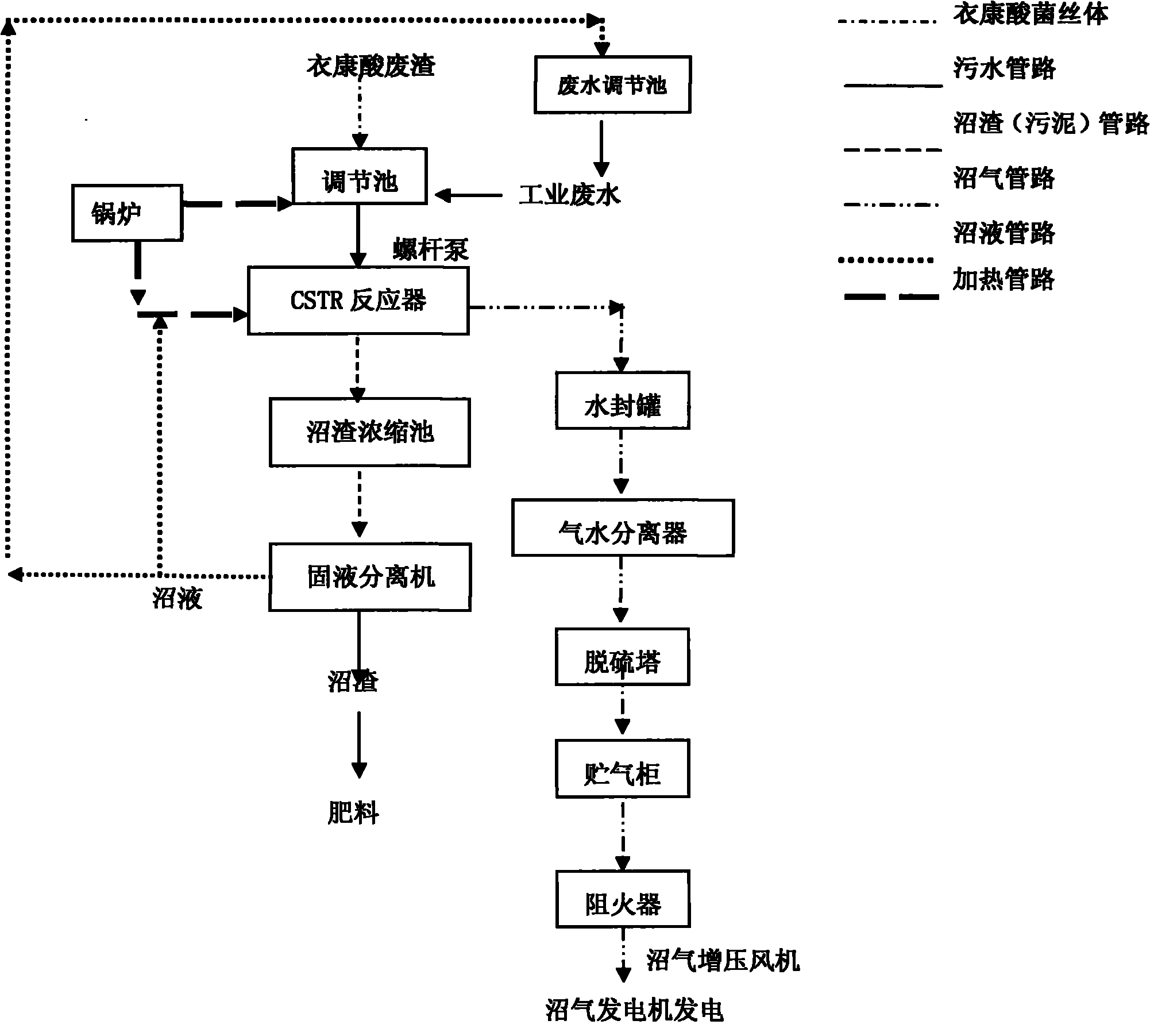

Image

Examples

Embodiment 1

[0028] Fully mix 1,000 kg of itaconic acid protein slag with 1,000 kg of industrial wastewater in the wastewater regulating tank, and stay in the wastewater regulating tank for 24 hours at a pH value of 6 and a temperature of 32°C to form a chemical oxygen demand of 160,000 mg / L Mix the solution, then inject the mixed solution into the continuous stirring anaerobic reactor, ferment at 35°C for 30 days to obtain biogas and biogas residue, pass the biogas through the water sealer and enter the steam-water separator to remove condensed water, and then enter The desulfurization tower removes hydrogen sulfide to prevent subsequent units from being corroded. The dried and desulfurized biogas enters the biogas tank and enters the biogas generator through the flame arrester to generate electricity. Biogas can also be used for boiler combustion; the biogas residue is separated by a solid-liquid separator , to obtain biogas slurry and dehydrated biogas residue, the biogas slurry is recyc...

Embodiment 2

[0030] Fully mix 3500 kg of itaconic acid mycelium with 3500 kg of industrial wastewater in the wastewater regulating tank, and stay in the wastewater regulating tank for 24 hours under the condition of Ph value of 7 and temperature of 35 °C to form a chemical oxygen demand of 80000 mg / L Then inject the mixed solution into the continuous stirring anaerobic reactor and ferment at 33°C for 30 days to obtain biogas and biogas residue. After the biogas passes through the water sealer, it enters the steam-water separator to remove condensed water, and then Enter the desulfurization tower to remove hydrogen sulfide to prevent subsequent units from being corroded. The dried and desulfurized biogas enters the biogas tank, and enters the biogas generator through the flame arrester to generate electricity. The biogas can also be used for boiler combustion; the biogas residue solid-liquid separator Separation to obtain biogas slurry and dehydrated biogas residue, the biogas slurry is recy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com