Crystalline silicon solar battery

A solar cell and crystalline silicon technology, applied in the field of solar cells, can solve problems such as reducing solar cell performance, increasing battery series resistance, and reducing device performance, so as to improve battery performance, increase short-circuit current and open-circuit voltage, and reduce recombination rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

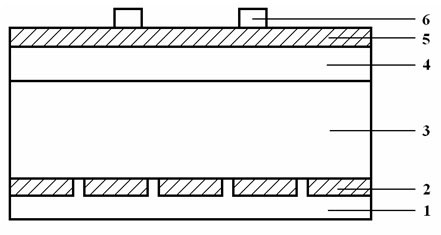

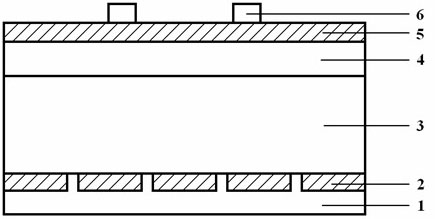

[0023] After the p-type Si base layer 3 is textured, an n-type Si diffusion layer 4 is formed on it by a diffusion method; a transparent ZnO layer co-doped with H and Nb is deposited on the n-type Si diffusion layer 4 by a magnetron sputtering method. The conductive thin film is the front ZnO-based thin film layer 5, and the ZnO transparent conductive thin film co-doped with H and Ga is deposited on the p-type Si substrate layer 3, which is the rear ZnO-based thin film layer 2; the main electrode of Ag is vacuum evaporated respectively by evaporation method Thick wire 6 and Al electrode 1, Ag main electrode thick wire 6 are deposited using mask technology, before Al electrode 1 is deposited, the ZnO-based thin film layer 2 on the back is etched and opened, and Al electrode 1 is formed into a dot electrode. The photoelectric conversion efficiency of the produced crystalline silicon solar cells is 18~21%.

Embodiment 2

[0025] After the p-type Si base layer 3 is textured, an n-type Si diffusion layer 4 is formed on it by a diffusion method; using a CVD method, on both sides of the n-type Si diffusion layer 4 and the p-type Si base layer 3, simultaneously deposit H The ZnO transparent conductive film co-doped with Al forms the front ZnO-based thin film layer 5 and the back ZnO-based thin film layer 2, and the back ZnO-based thin film layer 2 is deposited using mask technology; The main electrode thick wire 6 and the Al electrode 1 and the Ag main electrode thick wire 6 are deposited using mask technology, and the Al electrode 1 forms a linear electrode. The photoelectric conversion efficiency of the produced crystalline silicon solar cells is 18-22%.

Embodiment 3

[0027] After the p-type Si base layer 3 is textured, an n-type Si diffusion layer 4 is formed on it by a diffusion method; using a magnetron sputtering method, on the n-type Si diffusion layer 4 and the p-type Si base layer 3, double-sided Simultaneously deposit the ZnMgO transparent conductive film that H and Ga are co-doped to form the front ZnO-based thin film layer 5 and the back ZnO-based thin film layer 2. The mask plate technology is used when the back ZnO-based thin film layer 2 is deposited; The Ag main electrode thick wire 6 and the Al electrode 1 are evaporated, the Ag main electrode thick wire 6 is deposited using mask technology, and the Al electrode 1 forms a linear electrode. The photoelectric conversion efficiency of the produced crystalline silicon solar cells is 19~23%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com