Light sources for lighting organic electroluminescence (OEL) plants and manufacturing method thereof

A plant lighting and luminescence technology, which is applied in the field of plant growth regulation and optoelectronics, can solve the problems of complex blue-violet and red-orange light processes and structures, complex functional layer manufacturing processes, and the impact of light utilization efficiency, so as to improve light utilization efficiency , Improve light transmittance, ensure human health and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

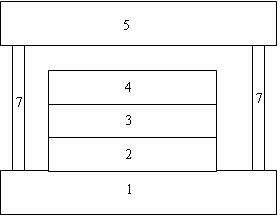

[0037] see figure 1 , a light source for organic electroluminescent plant lighting, mainly comprising an organic electroluminescent light source, the organic electroluminescent light source has a sealing cover formed by sealing and bonding a glass substrate 1 and a sealing cover 5 through an encapsulating glue 7; in the sealing cover One layer of positive electrode ITO thin film 2 is made on the inner surface of the glass substrate 1, and the glass substrate 1 and the ITO thin film 2 constitute an ITO glass substrate; On the surface of the ITO thin film of the ITO glass substrate, continue to vapor-deposit an organic electroluminescent material layer 3; On the organic electroluminescent material layer 3, the negative electrode metal electrode layer 4 is vapor-deposited; on the outer surface of the glass substrate 1 of the organic electroluminescent light source, a layer of light-to-light functional layer 6 is added to make the light-transfer functional layer 6. Part of the inc...

Embodiment 2

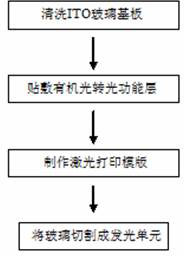

[0042] The preparation method of the light source for organic electroluminescent plant lighting according to Embodiment 1 of the present invention comprises the following steps:

[0043] a. Choose a cleaned ITO glass substrate;

[0044] b. on the ITO thin film surface of the ITO glass substrate in step a, vapor-deposit organic electroluminescence material layer;

[0045] c. Evaporating a metal electrode layer on the organic electroluminescent material layer in step b;

[0046] d. encapsulating each structural layer in steps a to c in a sealed cover formed by a glass substrate and a cover that are sealed and bonded by an encapsulant;

[0047] E. on the surface of the ITO glass substrate without the ITO thin film in step d, make a light-to-light functional layer with a hollow pattern;

[0048] f. cutting the glass in step e into light-emitting units to complete the production of light sources for organic electroluminescent plant lighting;

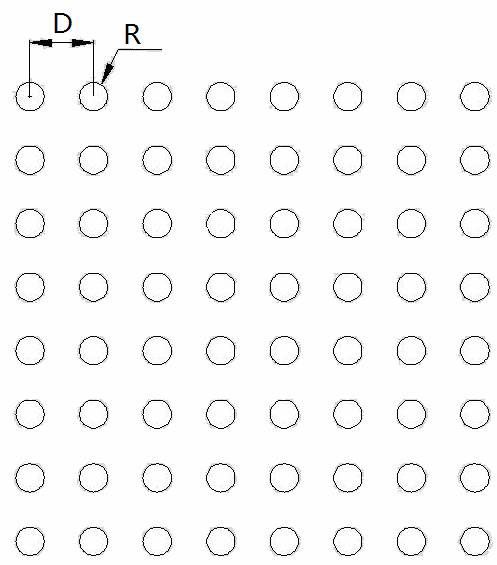

[0049] Wherein the hollow pattern o...

Embodiment 3

[0051] The manufacturing method of the light source for organic electroluminescent plant lighting in this embodiment is basically the same as that in Embodiment 2, except that:

[0052] The hollow pattern of the light-to-light functional layer in step e of the second embodiment can also be directly produced by etching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com