Method for producing polystyrene extruded sheets by using carbon dioxide foaming agent

A technology of polystyrene and carbon dioxide, which is applied in a field especially involving the use of carbon dioxide, a production of polystyrene foam extruded board, which can solve the problems of polystyrene extruded board restrictions and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

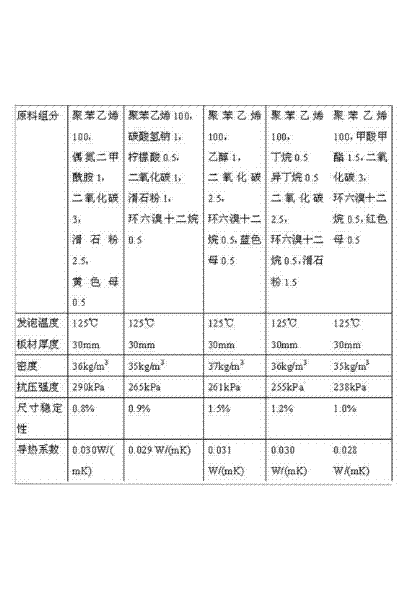

Examples

Embodiment 1

[0021] When the foaming agent other than carbon dioxide is azodicarbonamide (AC) solid chemical foaming agent, mix 100Kg of polystyrene particles with 1Kg of azodicarbonamide (AC), 2.5Kg of processing aid talcum powder, yellow 0.5 Kg of parent material is fully mixed in the mixer, directly added to the hopper of the extruder through the feeder, and heated by the No. 1 extruder to raise the temperature to above 180°C for polystyrene, so that the polystyrene material is melted and mixed , to form a polymer melt, inject 3Kg of carbon dioxide foaming agent into the polymer melt at the middle position along the direction of the screw extruder path, form a foamable gel, and increase the temperature by adjusting the No. 1 extruder High system pressure, the pressure is 8 ~ 15MPa, the blowing agent is mixed with the polystyrene melt, this pressure is enough to prevent the formed plastic gel from actually foaming or enough to prevent the blowing agent in the foamable gel from losing unif...

Embodiment 2

[0023] When the foaming agent other than carbon dioxide is sodium bicarbonate and citric acid solid chemical foaming agent, polystyrene particles 100Kg, sodium bicarbonate 1Kg, citric acid 0.5Kg, talcum powder 1Kg, cyclohexabromododecane 0.5Kg is fully mixed in the mixer, directly added to the hopper of the extruder through the feeder, and heated by the No. 1 extruder to raise the temperature to above 180°C for polystyrene, so that the polystyrene material is melted and mixed. To form a polymer melt, inject 1Kg of carbon dioxide foaming agent into the polymer melt at the middle position along the path of the screw extruder to form a foamable gel, and increase the temperature by adjusting the No. 1 extruder System pressure, the pressure is 8 ~ 15MPa, the foaming agent is mixed with the polystyrene melt, this pressure is enough to prevent the formed plastic gel from actually foaming or enough to prevent the foaming agent in the foamable gel from losing uniformity dispersion. Af...

Embodiment 3

[0025] When the foaming agent other than carbon dioxide is ethanol liquid physical foaming agent, 100Kg of polystyrene particles, 0.5Kg of cyclohexabromododecane, and 0.5Kg of blue mother are fully mixed in the mixer, and then passed through the feeding machine. Add it directly into the hopper of the extruder, heat it through the No. 1 extruder to raise the temperature to above 180°C for polystyrene, melt and mix the polystyrene material to form a polymer melt, mix 1Kg of ethanol with 2.5Kg of carbon dioxide , at the middle position along the path of the screw extruder, inject it into the polymer melt to form a foamable gel, and increase the system pressure by adjusting the No. 1 extruder, the pressure is 8-15MPa, and the The blowing agent is mixed with the polystyrene melt at a pressure sufficient to prevent the resulting plastic gel from actually foaming or to prevent loss of uniform dispersion of the blowing agent within the foamable gel. After the No. 2 extruder and static...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com