Fluorescent molecular machine based on one-dimensional silicon nanowires and using method thereof

A technology of silicon nanowires and fluorescent molecules, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc. Small, easy to make array effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

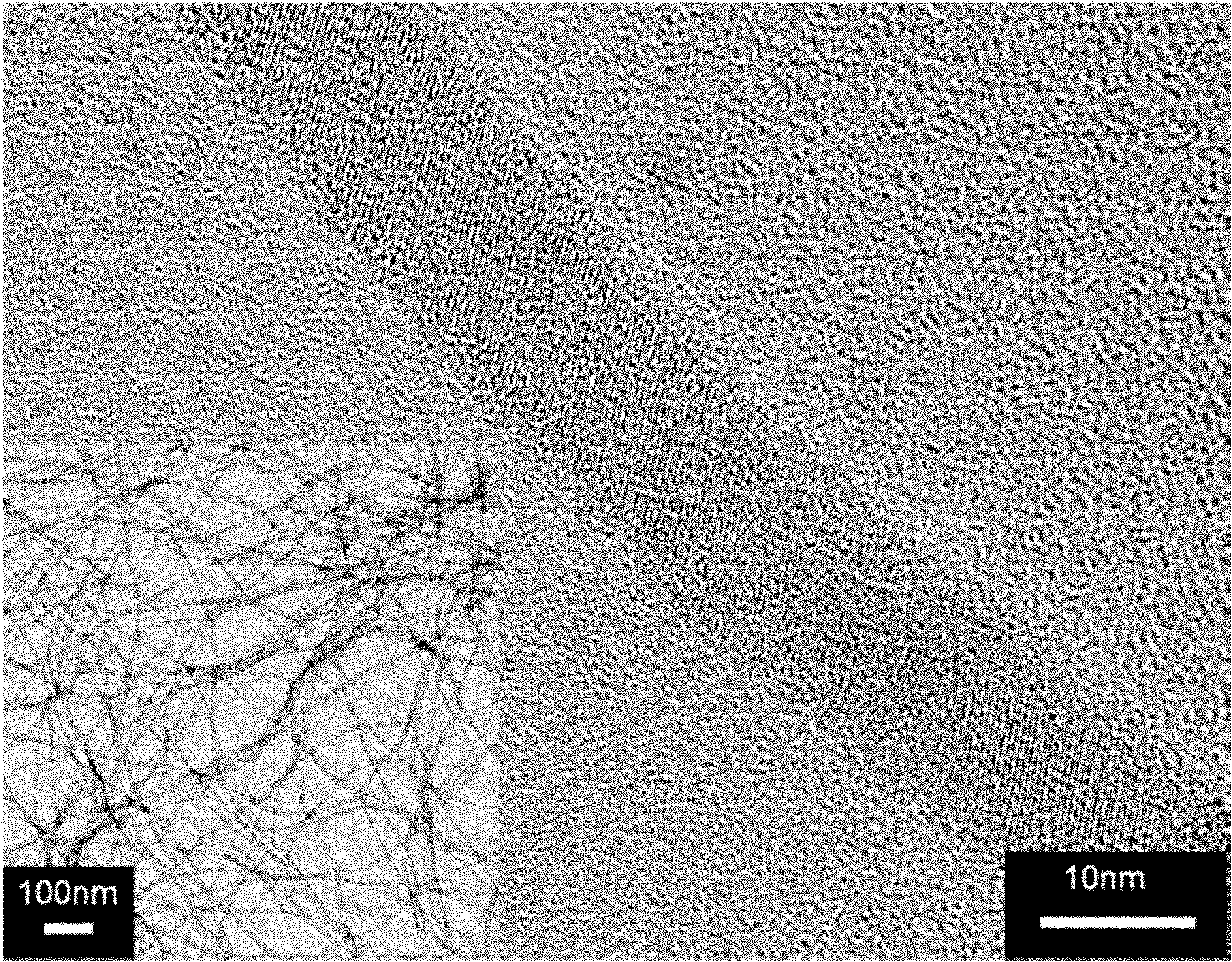

[0030] Place 1 gram of SiO in the middle of the alumina furnace tube of the horizontal tube furnace, then evacuate the alumina furnace tube to 1 Pa, and then pass a mixed gas of argon and hydrogen into the alumina furnace tube, wherein the hydrogen content accounts for 5% of the volume of the mixed gas. The air pressure of the alumina furnace tube was stabilized at 1000 Pa. Then the temperature of the tube furnace was raised to 1350° C., and after maintaining the temperature for 6 hours, the temperature of the tube furnace was naturally cooled. Finally, one-dimensional silicon nanowires are obtained in the tube furnace, and the diameter of the one-dimensional silicon nanowires is 8 nm to 10 nm, and the length is 1 μm to 10 μm. see figure 1 .

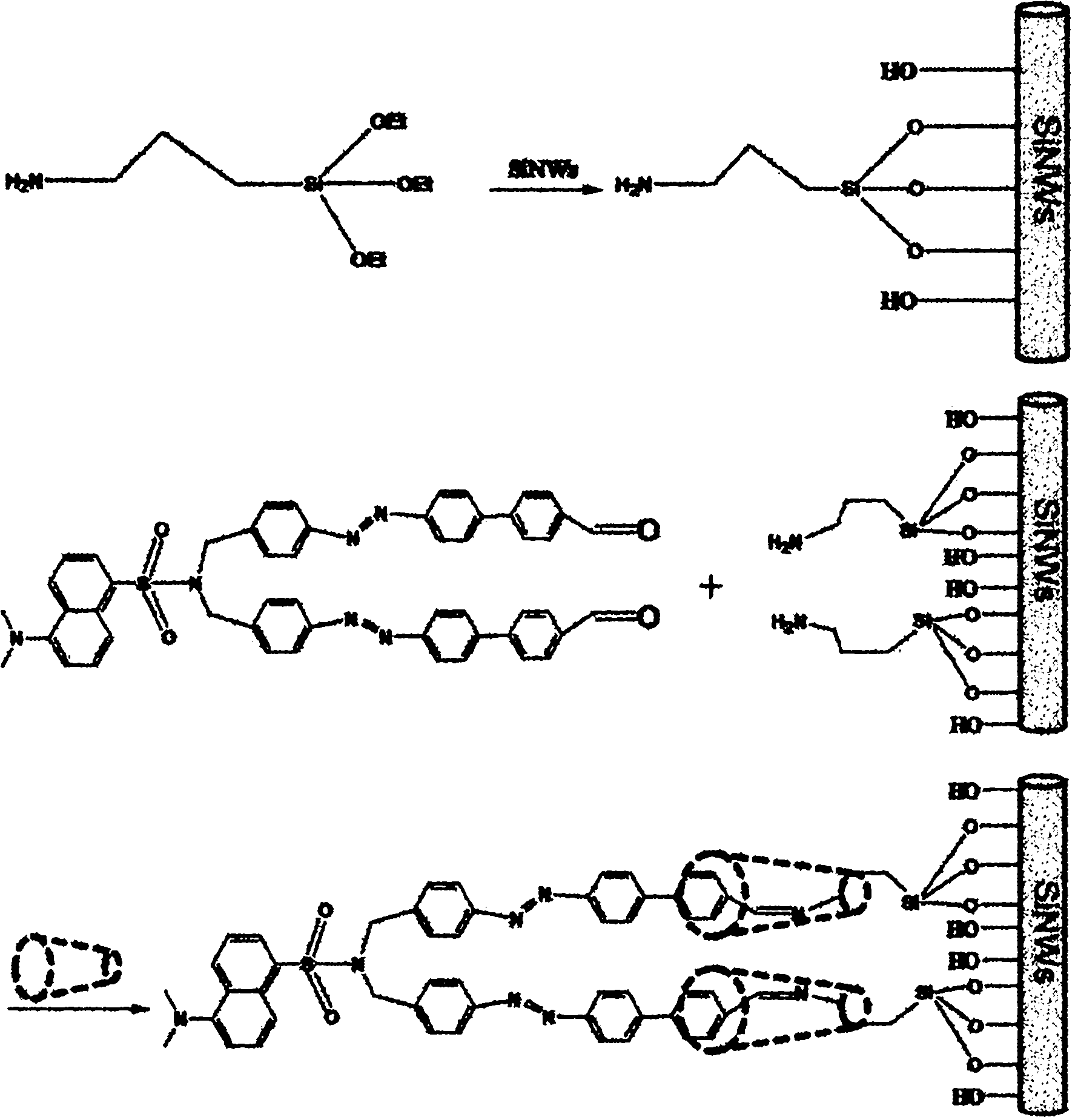

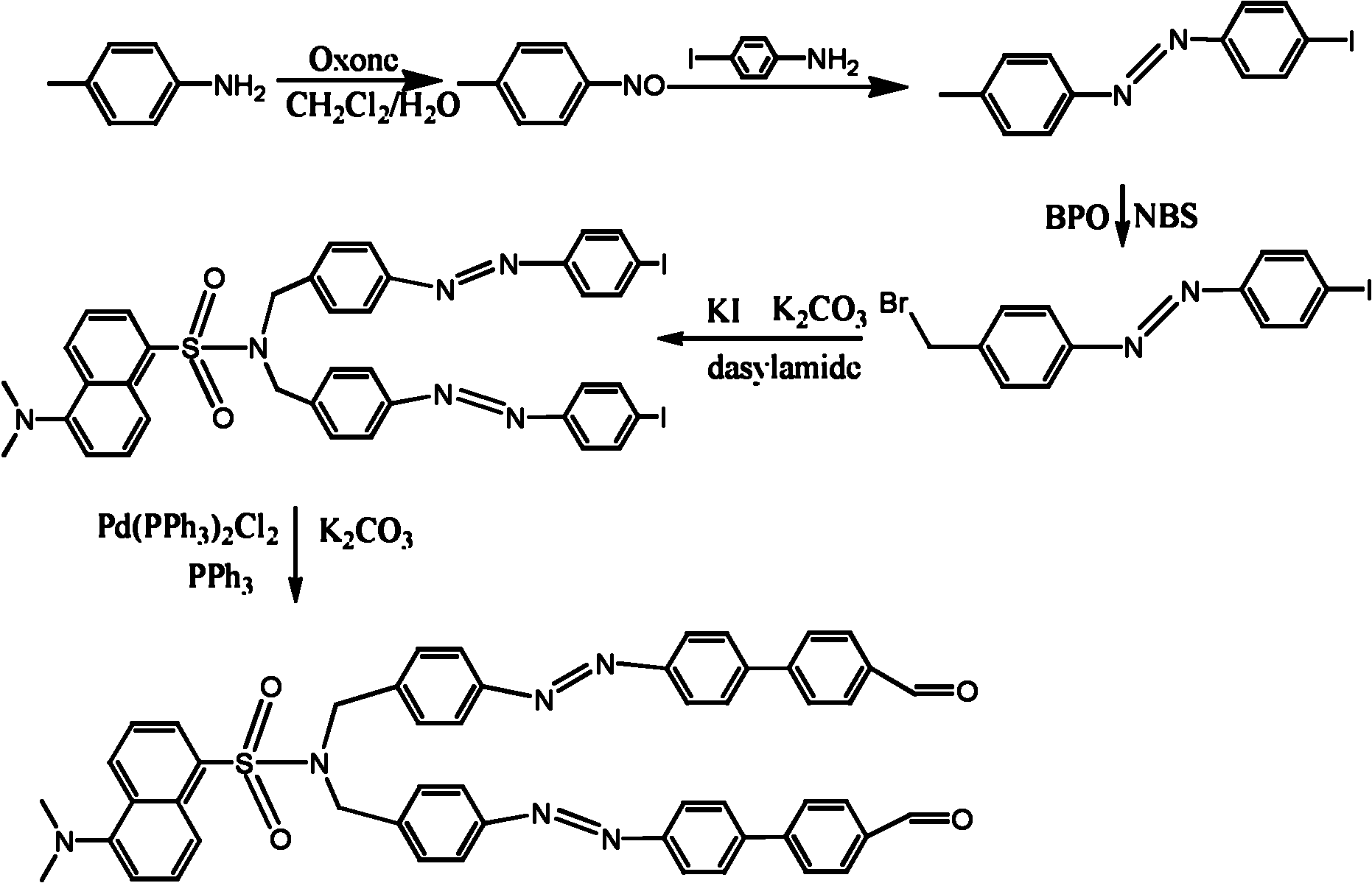

[0031] Add one-dimensional silicon nanowires treated with oxygen plasma in the round-bottomed flask connected with the water separator (it can be obtained by treating the one-dimensional silicon nanowires at a temperature of 50° C. in...

Embodiment 2

[0039] Place 1 gram of SiO in the middle of the alumina furnace tube of the horizontal tube furnace, then evacuate the alumina furnace tube to 1 Pa, and then pass a mixed gas of argon and hydrogen into the alumina furnace tube, wherein the hydrogen content accounts for 5% of the volume of the mixed gas. The air pressure of the alumina furnace tube was stabilized at 1000 Pa. Then the temperature of the tube furnace was raised to 1350° C., and after maintaining the temperature for 6 hours, the temperature of the tube furnace was naturally cooled. Finally, one-dimensional silicon nanowires are obtained in the tube furnace, and the diameter of the one-dimensional silicon nanowires is 8 nm to 10 nm, and the length is 1 μm to 10 μm. see figure 1 .

[0040] Add one-dimensional silicon nanowires treated with oxygen plasma into a round bottom flask connected with a water separator (it can be obtained by treating one-dimensional silicon nanowires in an oxygen plasma at a temperature ...

Embodiment 3

[0048] Place 1 gram of SiO in the middle of the alumina furnace tube of the horizontal tube furnace, then evacuate the alumina furnace tube to 1 Pa, and then pass a mixed gas of argon and hydrogen into the alumina furnace tube, wherein the hydrogen content accounts for 5% of the volume of the mixed gas. The air pressure of the alumina furnace tube was stabilized at 1000 Pa. Then the temperature of the tube furnace was raised to 1350° C., and after maintaining the temperature for 6 hours, the temperature of the tube furnace was naturally cooled. Finally, one-dimensional silicon nanowires are obtained in the tube furnace, and the diameter of the one-dimensional silicon nanowires is 8 nm to 10 nm, and the length is 1 μm to 10 μm. see figure 1 .

[0049] Add the one-dimensional silicon nanowires treated with oxygen plasma into the round bottom flask connected with the water separator (it can be obtained by treating the one-dimensional silicon nanowires in oxygen plasma at a tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com