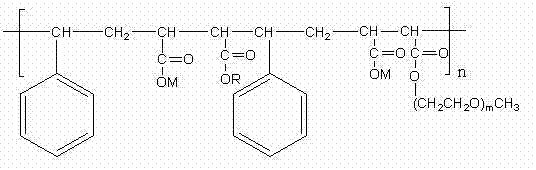

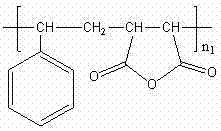

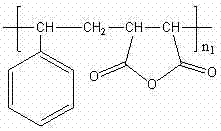

Comb-shaped amphiphilic modified styrene-maleic anhydride (SMA) tanning agent and preparation method thereof

An amphiphilic, tanning agent technology, applied in animal husbandry, small raw hide/big raw hide/leather skin/fur chemical treatment, application, etc., can solve poor emulsification and dispersion performance, affect retanning and fatliquoring effect, hydrophilic Insufficient softness, excellent retanning and fatliquoring performance, and excellent hydrophilicity can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The first step, get the catalyst of the SMA of 202 parts by mass, the fatty alcohol of 139.5 parts by mass, the polyethylene glycol monomethyl ether of 62.5 parts by mass and 2.0 parts by mass, join above-mentioned reactant in In a reactor equipped with a stirrer, a thermometer and a condensing device, add an organic solvent 2.5 times the total amount of reactants, react at 85° C. for 3 hours, and distill off the solvent under reduced pressure to obtain a reaction product. The average relative molecular mass of the SMA is 2000; the fatty alcohol is dodecyl alcohol; the polyethylene glycol monomethyl ether is MPEG-250; the organic solvent is dioxane; the catalyst For p-toluenesulfonic acid.

[0032] In the second step, neutralize with 20% alkaline aqueous solution until the pH of the reaction system is 7.0, and adjust the solid content of the product to 30%. The alkali of the alkaline aqueous solution is NaOH.

Embodiment 2

[0034] The first step, get the catalyst of the SMA of 202 parts by mass, the fatty alcohol of 140 parts by mass, the polyethylene glycol monomethyl ether of 75 parts by mass and 2.1 parts by mass, join above-mentioned reactant in In a reactor equipped with a stirrer, a thermometer and a condensing device, add an organic solvent 2.5 times the total amount of reactants, react at 80° C. for 3.5 hours, and distill off the solvent under reduced pressure to obtain a reaction product. The average relative molecular mass of the SMA is 4000; the fatty alcohol is C 12 ~C 14 Mixed alcohol; the polyethylene glycol monomethyl ether is MPEG-250; the organic solvent is butanone; the catalyst is p-toluenesulfonic acid.

[0035] In the second step, neutralize with 20% alkaline aqueous solution until the pH of the reaction system is 6.5, and adjust the solid content of the product to 25%. The base of the alkaline aqueous solution is ammonia water.

Embodiment 3

[0037] The first step, get the catalyst of the SMA of 202 parts by mass, the fatty alcohol of 107 parts by mass, the polyethylene glycol monomethyl ether of 275 parts by mass and 2.9 parts by mass, join above-mentioned reactant in In a reactor equipped with a stirrer, a thermometer and a condensing device, add an organic solvent 3 times the total amount of reactants, react at 90° C. for 3 hours, and distill off the solvent under reduced pressure to obtain a reaction product. The average relative molecular mass of the SMA is 3000; the fatty alcohol is myristyl alcohol; the polyethylene glycol monomethyl ether is MPEG-550; the organic solvent is DMSO; the catalyst is sulfuric acid .

[0038] In the second step, neutralize with 20% alkaline aqueous solution until the pH of the reaction system is 7.0, and adjust the solid content of the product to 35%. The base of the solution is KOH.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com