Charge-detecting chip and manufacturing method thereof

A charge detection and chip technology, applied in circuits, discharge tubes, measuring devices, etc., can solve problems such as non-reusability, inability to fully meet test requirements, plasma damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

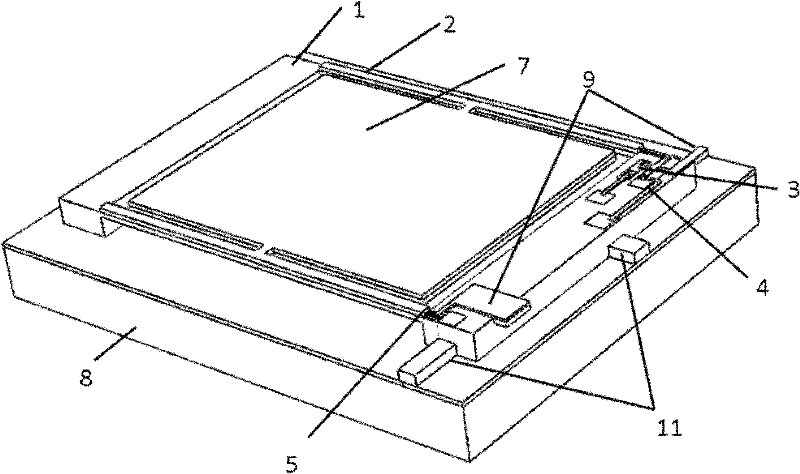

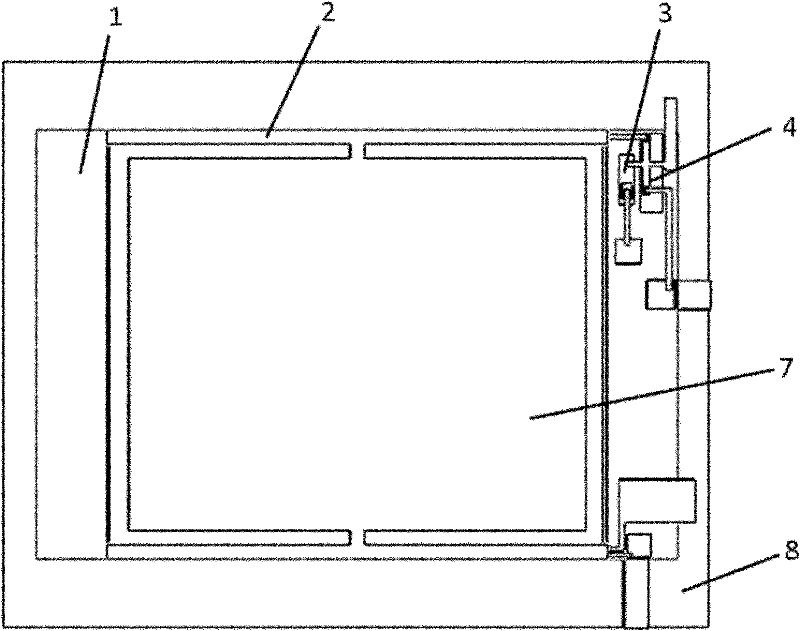

[0098] A charge detection chip that can be used to monitor plasma processing technology is prepared by adopting a monolithic integration method of microelectromechanical system (MEMS) technology and IC (CMOS) technology. Such as figure 2 As shown in Figure 3, the test unit of the chip is located on the substrate 8, and consists of five main functional components: the lower plate 6, the bi-material beam 2, the piezoresistor 5, the MOS switch 4, and the protection diode 3, among which:

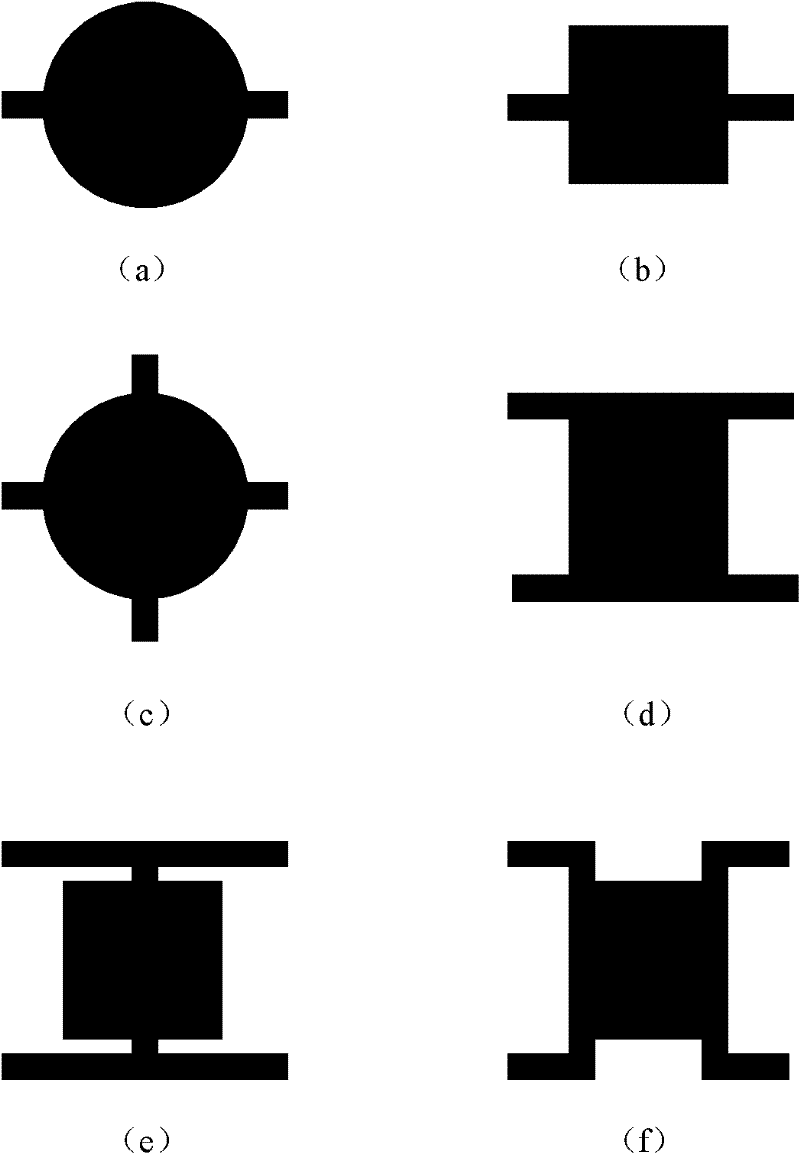

[0099] The double-material beam 2 is composed of a structural layer on the lower layer and a metal layer on the upper layer, and the shapes of the structural layer and the metal layer are completely coincident. The top view of the bimaterial beam 2 is a centrosymmetric figure, such as Figure 4 shown. In order to accumulate enough charges on a limited chip area, the middle of the bimaterial beam 2 is designed as a large-area rectangular flat plate, and its upper layer is the metal pole plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com