Absorbent polymer extinguishing agent preparation method

A technology of water-absorbing resin and fire extinguishing agent, which is applied in the direction of fire prevention equipment, etc., and can solve problems such as the timing of adding initiators and crosslinking agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

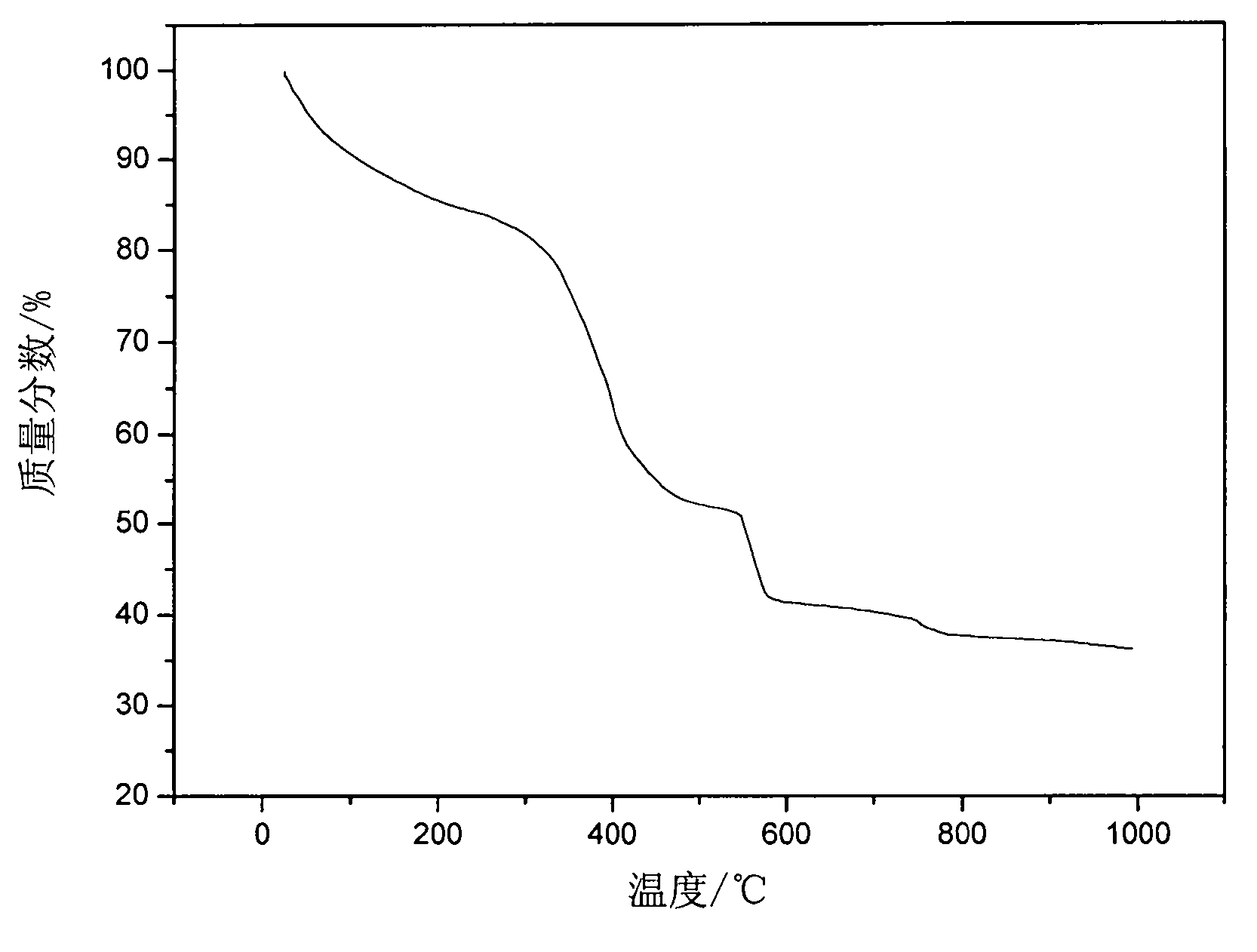

[0048] Implement the preparation method of above-mentioned a kind of water-absorbing resin fire extinguishing agent, the prepared water-absorbing resin fire extinguishing agent, carried out the test of the water absorption ratio, water absorption rate and water retention rate of resin as follows:

[0049] Determination of water absorption ratio:

[0050] Accurately weigh 0.2g dry sample of water-absorbent resin in a beaker, add a certain mass of M 0 After standing for 30 minutes, filter the water-absorbing resin with a 200-mesh sampling sieve, let the water-absorbing resin stand on the sampling sieve for a period of time, until the water-absorbing resin is anhydrous and filter out, and then weigh the filtered water quality M 1 .

[0051]

[0052] The measured water absorption rate is 1000g / g

[0053] Determination of water absorption rate:

[0054] Accurately weigh 0.2g dry sample of water-absorbent resin into a beaker, add a certain quality of distilled water, let it st...

Embodiment 1

[0063] Implement the preparation method of a kind of water-absorbing resin fire extinguishing agent of the present invention, this method is carried out according to the following steps:

[0064] (1) Place a beaker containing 8 parts of acrylic acid solution in an ice-water bath, then add 30% sodium hydroxide solution into the acrylic acid solution, stir until the precipitate disappears, and then obtain acrylic acid neutralizing solution, which is ready for use ;

[0065] (2) Put the reactor into a water bath, then add 20ml of distilled water into the reactor, heat it to about 50°C, then add 1 part of carboxymethyl cellulose (CMC) into the reactor, stir and gelatinize for about 15min Until carboxymethyl cellulose is in the form of a gel;

[0066] (3) Continuously feed nitrogen into the reactor, then add potassium persulfate with a mass of 0.05 parts as an initiator, and initiate the reaction for about 10 minutes;

[0067] (4) Add an acrylic acid solution with a neutralizatio...

Embodiment 2

[0074] Implement the preparation method of a kind of water-absorbing resin fire extinguishing agent of the present invention, this method comprises the following steps:

[0075] (1) Place a beaker containing 10 parts of acrylic acid solution in an ice-water bath, then add a 30% sodium hydroxide solution into the acrylic acid solution, stir until the precipitate disappears, and obtain acrylic acid neutralization solution, which is ready for use ;

[0076] (2) Put the reactor into a water bath, then add 20ml of distilled water into the reactor, heat it to about 60°C, then add 2 parts of carboxymethyl cellulose (CMC) into the reactor, stir and gelatinize for about 18min Until carboxymethyl cellulose is in the form of a gel;

[0077](3) Continuously feed nitrogen into the reactor, then add potassium persulfate with a mass of 0.10 parts as an initiator, and initiate the reaction for about 20 minutes;

[0078] (4) Add an acrylic acid solution with a neutralization degree of about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com