UV (ultraviolet) photo-cured acrylic resin composition

A technology of acrylic resin and composition, applied in the direction of epoxy resin coating, coating, etc., can solve the problems of unsuitable furniture processing veneer process, unsatisfactory adhesion, difficulty in achieving flexibility, etc., to achieve good protection, wide Good range of use and good clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

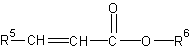

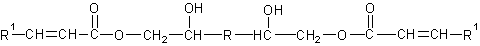

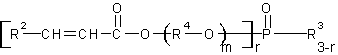

Method used

Image

Examples

Embodiment 1

[0054] The main components of the UV photocurable acrylic resin composition of the present invention include: 17wt% thermoplastic acrylic resin (molecular weight: 50,000), 48wt% polyurethane modified epoxy acrylic resin (molecular weight: 800, viscosity at 25°C: 3000MPa·s), 18wt% bisphenol A Epoxy acrylic resin (viscosity at 25°C is 20000MPa s), 10wt% reactive diluent, 0.7wt% acrylate phosphate (acid value is 300mgKOH / g), 1.3wt% auxiliary agent, 5wt% photoinitiator 。

Embodiment 2

[0056] The main components of the UV photocurable acrylic resin composition of the present invention include: 18wt% thermoplastic acrylic resin (molecular weight 70000), 48wt% polyurethane modified epoxy acrylic resin (molecular weight 1500, viscosity at 25°C is 3800MPa·s), 17wt% bisphenol A Epoxy acrylic resin (viscosity of 35000MPa s at 25°C), 12wt% reactive diluent, 1wt% acrylate phosphate (acid value 280mgKOH / g), 1.3wt% additive, 2.7wt% photoinitiator 。

Embodiment 3

[0058] The main components of the UV photocurable acrylic resin composition of the present invention include: 19wt% thermoplastic acrylic resin (molecular weight 80000), 48wt% polyurethane modified epoxy acrylic resin (molecular weight 2000, viscosity at 25°C is 5000MPa s), 18wt% bisphenol A Epoxy acrylic resin (viscosity of 40000MPa s at 25°C), 8wt% active diluent, 0.8wt% acrylate phosphate (acid value: 310mgKOH / g), 1.2wt% auxiliary agent, 5wt% photoinitiator 。

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com