Illumination apparatus and manufacture method thereof

A technology for lighting equipment and equipment, applied in lighting and heating equipment, lighting devices, components of lighting devices, etc., can solve problems such as not providing brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

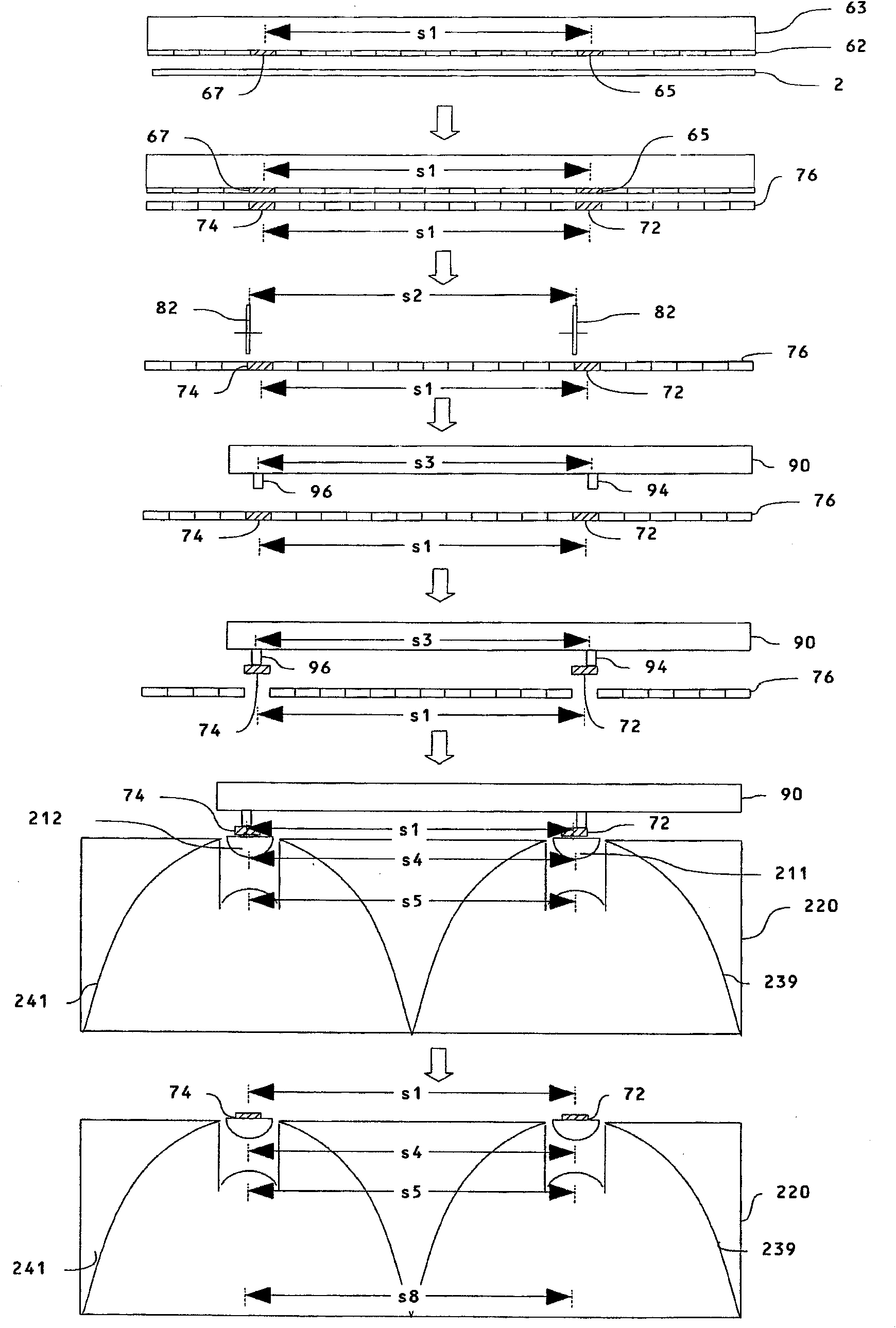

[0161] figure 1 A method of forming a microscopic illumination device is shown in the first example in . In a first step, the monolithic light-emitting element wafer 2 is irradiated using at least one mask 62 mounted on a substrate 63 . For the purposes of this specification, the term monolithic means consisting of one solid or complete component.

[0162] In a second processing step, an array 76 of light-emitting elements is formed on the monolithic wafer 2 . Each element has a position and orientation defined by mask 62 . The mask includes an array of regions, each region defining the structure of at least one layer of the LED chip. Regions 65 and 67 represent the first LED chip and the second LED chip and have a separation s1 as shown. During exposure to wafer 2 through the mask, elements 72 and 74 are formed from regions 65 and 67 of the mask. The spacing s1 of the elements 72, 74 is substantially the same as the spacing of the mask regions 65, 67, and the orientation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com