Method for controlling pH value of spray slurry in magnesium-based seawater process ship desulfurization system

A desulfurization system and control method technology, applied in the field of flue gas desulfurization, can solve problems such as increased equipment corrosion, low desulfurization efficiency, system wear and enhanced precipitation, and achieve the effect of up-to-standard operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the examples.

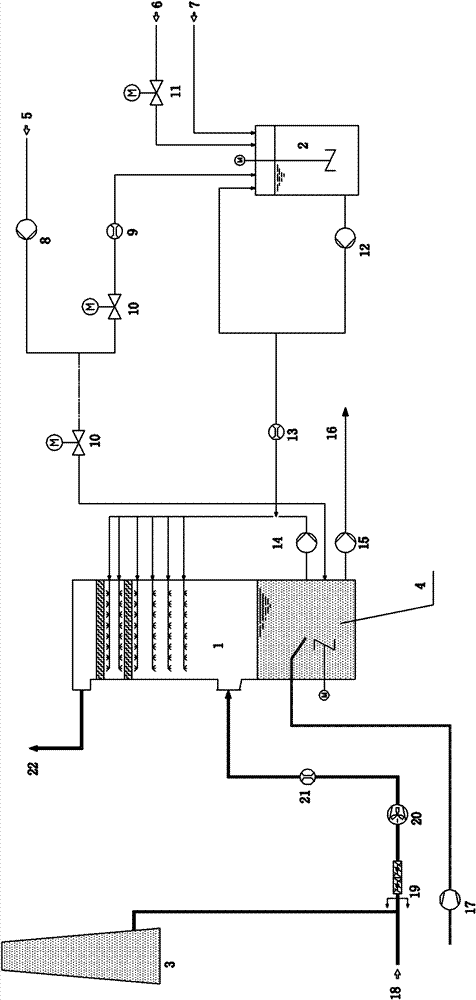

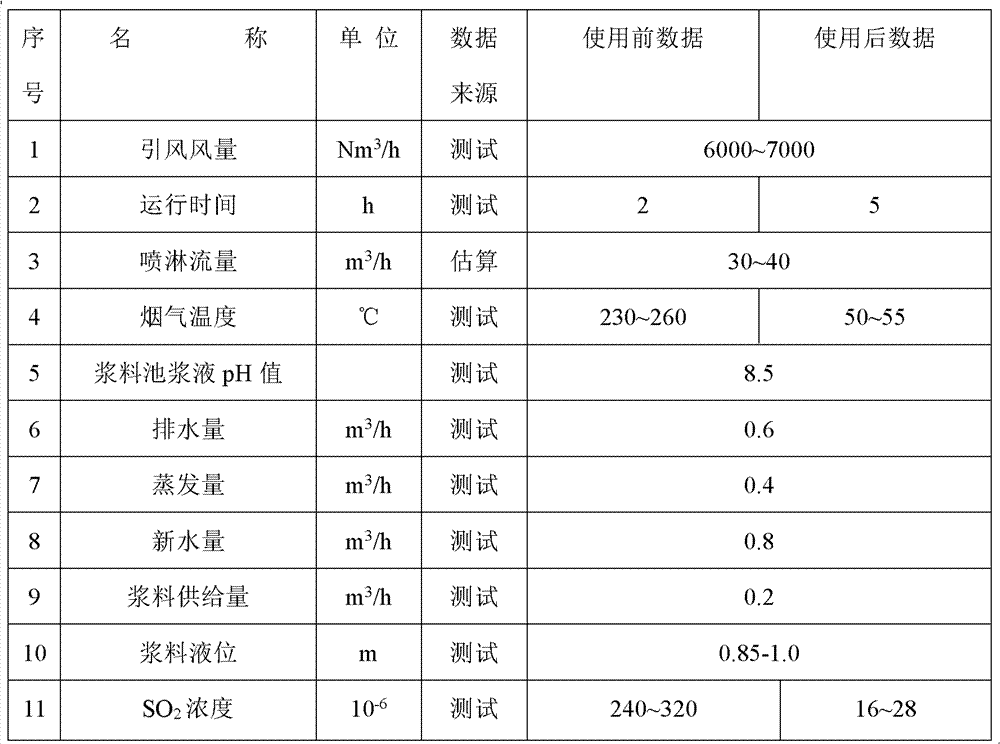

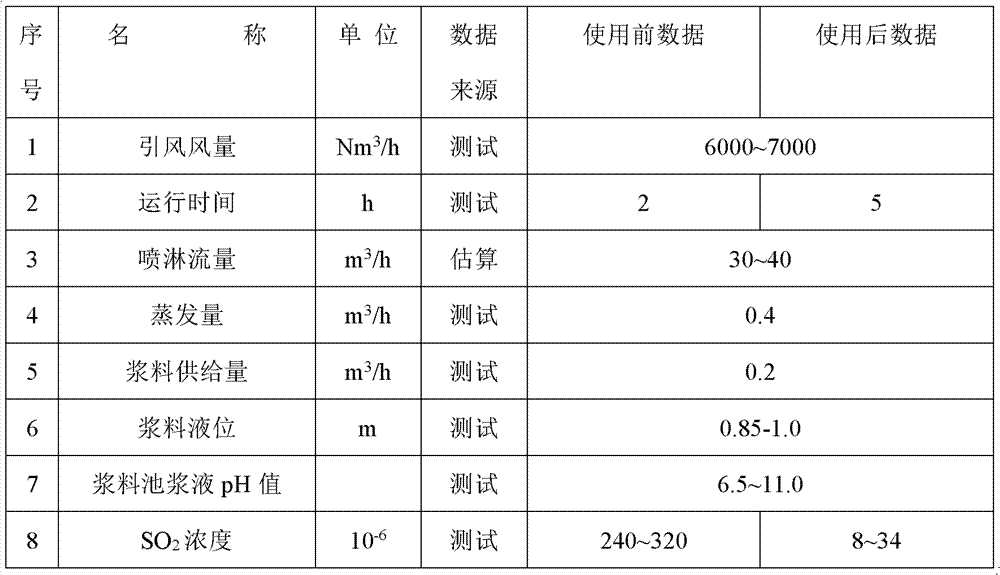

[0020] On a container ship, the pH value control system of the spray slurry is used to control SO 2 Removal effect test. Use fuel oil with a sulfur content of 0.71-0.93% m / m, normal sea navigation, the air volume of exhaust gas emitted by the main engine is about 50,000m 3 / h. The device is powered by 440V, 60Hz three-phase AC ship power, and the induced air volume is less than 10000m 3 / h, the power of the induced draft fan is adjustable from 10 to 30kW, the power of the slurry frequency conversion pipeline pump is adjustable below 3kW, the pressure is 3.5 to 4.0atm, and the slurry supply flow rate is 0.1 to 1.0m 3 / h adjustable (Mg(OH) 2 The slurry concentration is less than 25%). The power of the circulating spray pump is adjustable from 10 to 30kW, and the slurry spray is less than 100m 3 / h is adjustable. Use two different modes to run continuously for 5 hours respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com