Well killing fluid and its preparation method

A killing fluid and brine technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high cost of sodium formate, difficult to operate, difficult to control volume growth, etc., to reduce corrosion rate, not easy to precipitate, The effect of avoiding harm

Active Publication Date: 2022-06-03

PETROCHINA CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In the process of preparing the kill fluid of the sodium formate system, since sodium formate is solid, it is necessary to dissolve the solid sodium formate to prepare a sodium formate solution, but in the process of preparing the sodium formate solution, after adding the solid sodium formate to water, the volume of the water will increase. However, the volume increase is difficult to control and difficult to operate, resulting in a large difference between the final prepared killing fluid density and the required killing fluid density, affecting the well killing operation and posing safety hazards

In addition, the density of sodium formate solution is up to 1.35g / cm 3 , the highest density of the prepared sodium formate system kill fluid is 1.55g / cm 3 , it is impossible to prepare a higher density kill fluid

Moreover, the cost of sodium formate is relatively high, which increases the cost of well killing operations

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

[0066] Wherein, the stirring time can be set and changed as required. In the embodiment of the present invention, the time of stirring

Embodiment 1

[0081] The mass percentage is 87.1% and the density is 1.40 g / cm

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Login to View More

Abstract

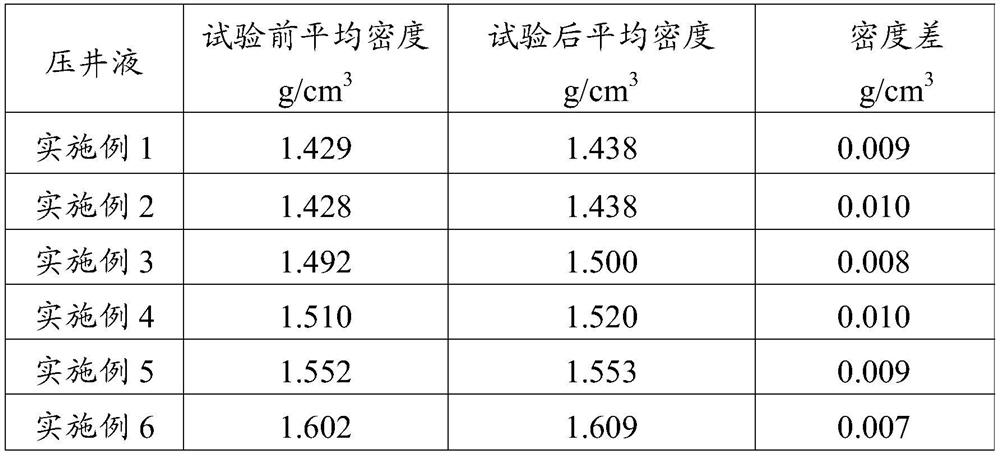

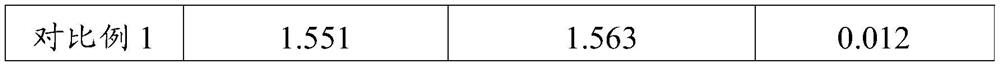

The invention discloses a killing fluid and a preparation method thereof, belonging to the technical field of oil field workover. The killing fluid includes the following components in mass percentage: brine 61.6%-87.1%, alkaline scale inhibitor 1%-2%, oil-soluble temporary plugging agent 0.5%-1.0%, modified attapulgite 4%- 7%, calcium carbonate 7%-30%, wetting agent 0.2%-0.5%, and the balance is defoamer. The density of brine is 1.35~1.43g / cm 3 , and the brine contains calcium ions with a concentration of 14-19g / L. The density of alkaline scale inhibitor is 1.40g / cm 3 , The hydrogen ion concentration index is 13-14. The modified attapulgite is attapulgite processed by ultrasonic cavitation. By adding brine, alkaline scale inhibitor, modified attapulgite and cooperating with other components, the well killing fluid has high temperature resistance, high density, low corrosion, scale dissolution and scale inhibition, temporary plugging, It is easy to prepare, easy to operate and low in cost, and improves the safety in the process of killing wells. Moreover, after the well killing fluid is used for operation, the production recovery rate of oil and gas wells is above 90%, and at the same time, the well killing fluid self-decomposes and flows back with the negative pressure of the operation.

Description

Well killing fluid and preparation method thereof technical field The present invention relates to a kind of well kill fluid and preparation method thereof, belong to the technical field of oil field workover. Background technique [0002] In the oil field production and development process, in order to ensure the normal production of oil and gas wells, it is necessary to carry out workover operations on the oil and gas wells. In the workover operation, in order to balance the fluid pressure in the formation and ensure the safety of the workover operation, the density is usually 1.5g / cm 3 above The fluid is used as the killing fluid, and the killing fluid is used for the killing operation. At present, the commonly used density is 1.4g / cm 3 The above killing fluid is a sodium formate system killing fluid, which includes the following qualities Percentage of components: sodium formate 37.40%-44.21%, attapulgite 2.56%-3.46%, conditioner 1# 0.1% ~1%, Regulator 2#...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K8/508

CPCC09K8/5045C09K8/508C09K2208/32

Inventor 尤秋彦樊松林董军尤志良王小芳张祖峰邵彦锋安封伦何晓吴国宏李影

Owner PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com