Surface infiltrated wood fiber board and production method thereof

A technology of wood fiber board and surface infiltration, applied in the field of wood fiber board, can solve the problem of no profit space, etc., and achieve the effects of reduced moisture content, complete shape, and small internal friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

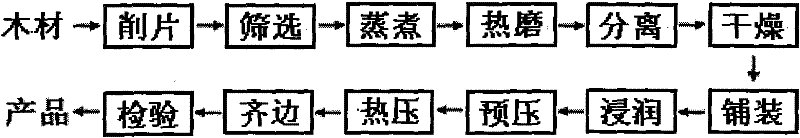

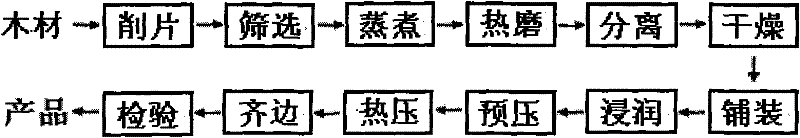

Method used

Image

Examples

Embodiment 1

[0035] 1. Feeding ingredients and parts by weight: 85 parts of wood fiber, 30 parts of water, 3 parts of phenolic resin glue and 2 parts of ferrous ammonium phosphate.

[0036] 2. Production method:

[0037] The raw wood is cut into thin slices with a length of 20 mm, a thickness of 4 mm, and a width of 20 mm with a chipper, and a 20-mesh vibrating screen is used to remove unqualified chips. Wood chips are cooked with saturated steam, the steam pressure is 0.60MPa, and the cooking time is 5 minutes. The steamed wood chips are separated into wood fibers with a heat grinder. Control the temperature at 250°C with a pipeline airflow dryer for 8 seconds, and the moisture content of the dry wood fiber is 10%. The dry wood fiber is laid on the slab conveyor by air-laying machine. Add phenolic resin glue and ferrous ammonium phosphate into the aqueous solution, atomize and spray the aqueous solution onto the surface of the wood fiber slab for infiltration. The wood fiber slab that...

Embodiment 2

[0040] 1. Feeding ingredients and parts by weight: 85 parts of wood fiber, 27 parts of water and 4 parts of phenolic resin glue.

[0041] 2. Production method:

[0042]The raw wood is cut into thin slices with a length of 15 mm, a thickness of 4 mm, and a width of 15 mm with a chipper, and a 10-mesh vibrating screen is used to remove unqualified debris. Wood chips are cooked with saturated steam, the steam pressure is 0.55MPa, and the cooking time is 5 minutes. The steamed wood chips are separated into wood fibers with a heat grinder. Control the temperature at 280°C with a pipeline airflow dryer for 6 seconds, and the moisture content of the dry wood fiber is 8%. The dry wood fiber is laid on the slab conveyor by a mechanical laying machine. The phenolic resin glue is added into the aqueous solution, and the aqueous solution is atomized and sprayed onto the surface of the wood fiber slab for infiltration. The wood fiber slab that has been soaked on the surface is pre-pres...

Embodiment 3

[0045] 1. Feeding ingredients and parts by weight: 87 parts of wood fiber, 34 parts of water and 3 parts of ferrous ammonium phosphate.

[0046] 2. Production method:

[0047] The raw wood is cut into thin slices with a length of 25 mm, a thickness of 2 mm, and a width of 20 mm with a chipper, and a 20-mesh vibrating screen is used to remove unqualified debris. Wood chips are cooked with saturated steam, the steam pressure is 0.68MPa, and the cooking time is 3 minutes. The steamed wood chips are separated into wood fibers with a heat grinder. Control the temperature at 180°C with a pipeline airflow dryer for 10 seconds, and the moisture content of the dry wood fiber is 9%. The dry wood fiber is laid on the slab conveyor by air-laying machine. Add ferrous ammonium phosphate into the aqueous solution, atomize and spray the aqueous solution onto the surface of the wood fiber slab for infiltration. The wood fiber slab that has been soaked on the surface is pre-pressed, the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com