Method for manufacturing corrugated cardboard sculpture

A corrugated cardboard and production method technology, applied in decorative arts, decorative structures and other directions, can solve the problems of unseen literature reports and practical applications, low connection strength of sculpture bodies, complicated processes, etc., and achieve low material and production costs, bright colors. , the effect of strong sense of body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below using the drawings and examples.

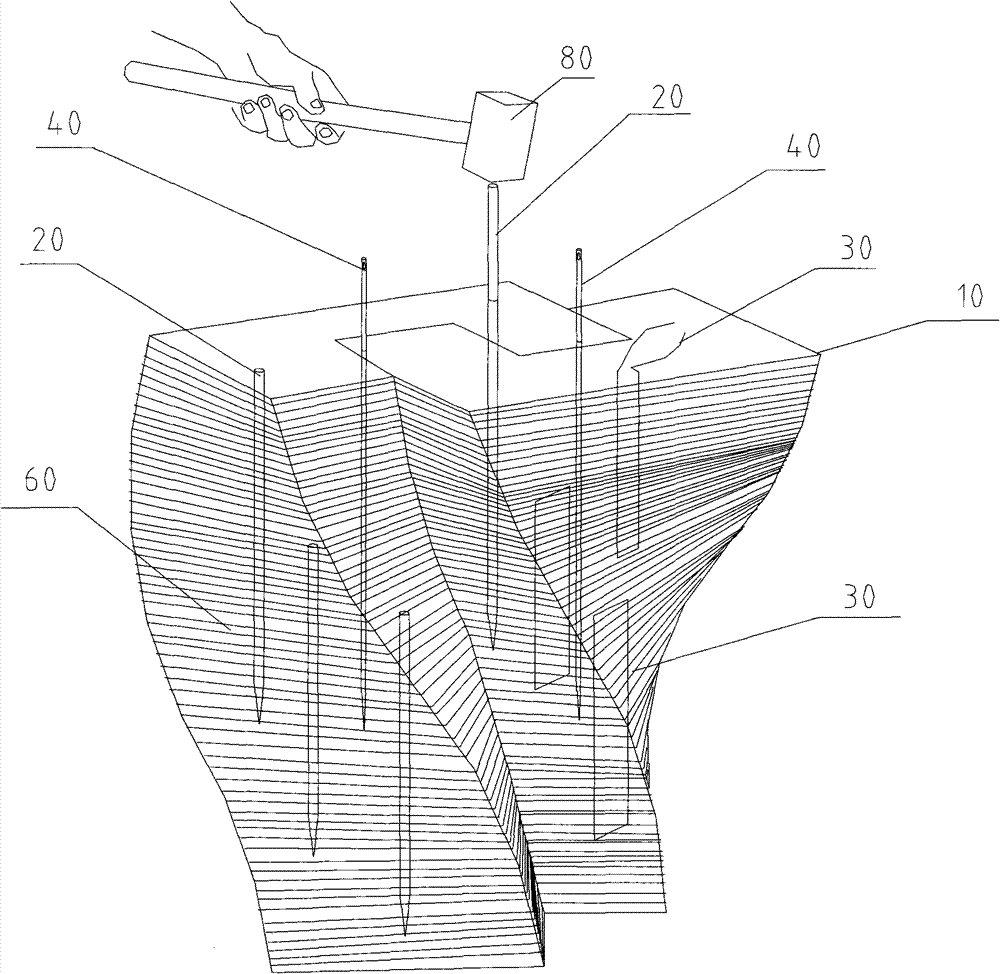

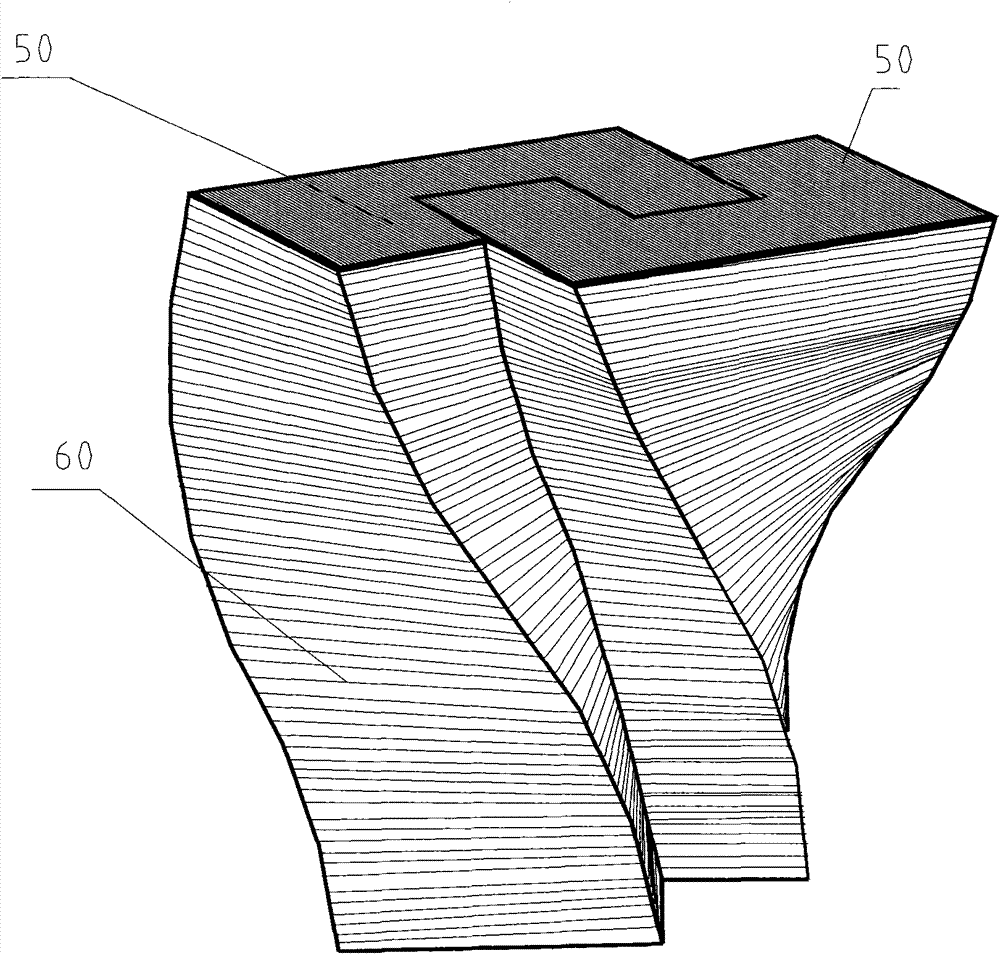

[0025] refer to figure 1 and figure 2 , the manufacture method of corrugated cardboard sculpture of the present invention comprises the following steps:

[0026] (a): Design, first of all, carry out the shape design of the sculpture, and draw the draft of the appearance effect and the schematic draft of the internal structure.

[0027] (b): material selection, the source of corrugated cardboard materials can generally have two ways: 1. waste corrugated cardboard packaging boxes; 2. finished corrugated cardboard for packaging boxes. Choose high-quality, relatively flat corrugated cardboard with consistent material and thickness, generally 3mm to 10mm, with 3, 5 or 7 layers.

[0028] (c): Cutting the material, according to the specific size and shape requirements of the sculpture design, draw the cutting boundary on the corrugated cardboard, and cut it accurately with a paper knif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com