Microwave-assisted solid-liquid reaction ball-milling device and process for preparing nano-oxide powder

A nano-oxide, microwave-assisted technology, applied in the field of stainless steel materials, to achieve the effects of reducing high preparation temperature, solving serious pollution, and uniform reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

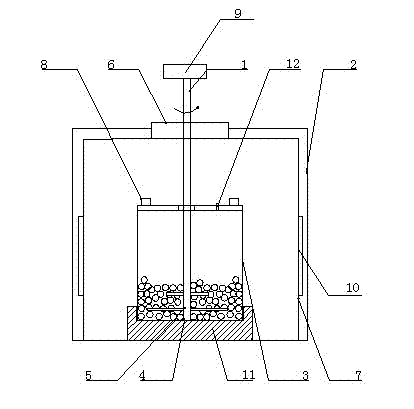

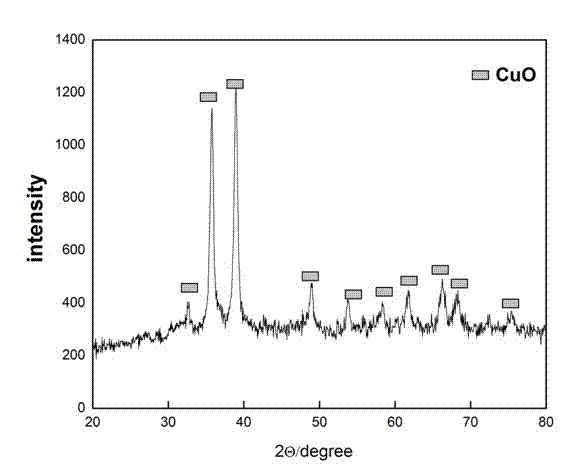

[0033] Example 1: Choose a microwave oven with a power of 1300W, first put 500 grams of ceramic grinding balls 4 and 10 grams of basic copper carbonate powder in the ceramic ball mill 3, and then add water to the container. The amount of water injected is 600 grams of the container . Then open the oven door 7 of the microwave oven, and put the ceramic ball mill pot 3 into which the basic copper carbonate has been added into the center of the microwave oven 2, and the lower part is fixed with a fixed base 11.

[0034] Rotate the sealing device 6 counterclockwise, open the top hole, insert the rotating shaft 1 into the ceramic ball mill jar 3 through the top hole, and insert the PTFE stirring rod 5 to the bottom of the ceramic ball mill jar 3, and then lock the fixing mechanism 8 , And ensure that the exhaust hole 12 of the fixing mechanism 8 is opened, and at the same time fix the ceramic ball mill jar 3, put on the sealing device 6, rotate clockwise tightly, and close the microwa...

example 2

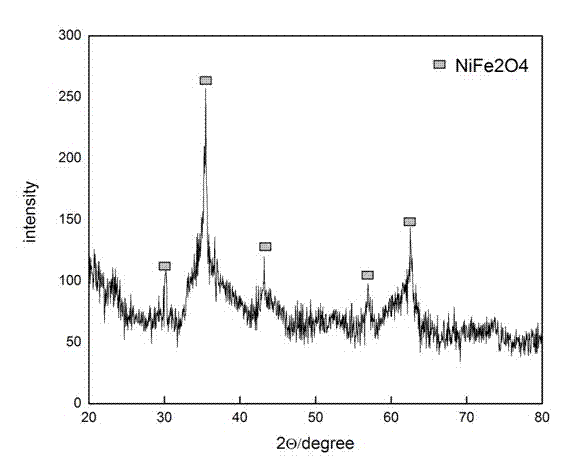

[0040] Example 2: Take 10 grams of basic nickel carbonate particles with an average particle diameter of 1 to 3 mm and put them in the ball mill 3, then add 500 grams of stainless steel mill balls 4 with a diameter of less than 1.5 mm into it, and then put them in the ball mill 3 Add 600 grams of deionized water as the ball milling medium.

[0041] Then put the ball mill jar 3 into the microwave oven 2 according to the method of Example 1, cover the fixing mechanism 8 of the ball mill jar 3 and the sealing device 6 of the microwave oven 2, connect the PTFE stirring rod 5 to the motor 9, and The other section of the PTFE stirring rod 5 is inserted into the bottom of the ball mill tank 3, and then the connection between the motor 9 and the PTFE stirring rod 5 is locked and fixed, and the furnace door is closed.

[0042] Adjust the motor speed to 235 r / min, and then turn on the microwave oven 2 to make it emit microwaves, and the microwave power is adjusted to 1024W. Time positioning...

Embodiment 3

[0044] Example 3: Take 10 grams of metal zinc particles with an average particle size of 1 to 3 mm, 400 grams of ceramic grinding balls with a diameter of 1.5 mm, and a ball-to-battery ratio of 40:1. Place them in the ball mill 3 and add about 500 g of deionized Water is used as ball milling fluid.

[0045] Control the microwave power of the microwave oven 2 to 1024 W, and the ball mill to control the speed of 235 r / min for wet ball milling; 30 hours later, sampling and testing, the powder particle size meets the process design requirements, stop the ball milling; suction filter, the filter residue at 50 ℃, vacuum degree For 10 -1 After drying under Pa, pure ZnO nano powder is obtained. After testing, the particle size of the obtained ZnO nano powder is about 50nm, and the purity is above 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com