Dephosphorization method for glyphosate wastewater

A treatment method, glyphosate technology, applied in natural water treatment, water/sewage multi-stage treatment, oxidized water/sewage treatment, etc., can solve the problem of phosphorus removal in wastewater that is rarely involved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

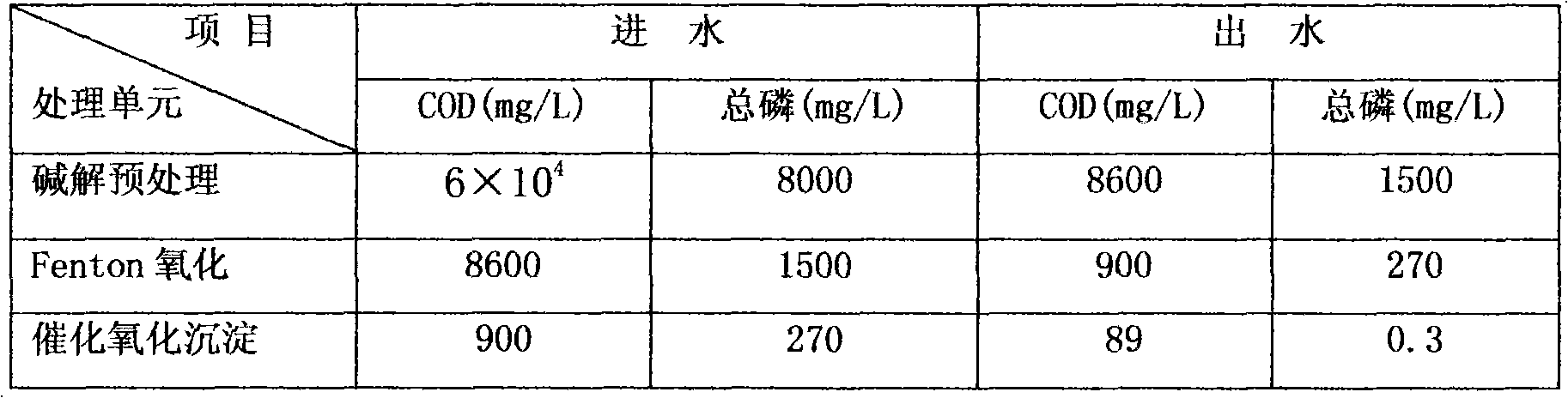

Embodiment 1

[0016] The glyphosate wastewater from a technology company in Guangxi was used as the water to be treated, and the phosphorus removal treatment was carried out by alkaline hydrolysis and precipitation reaction, Fenton oxidation reaction and catalytic reprecipitation process.

[0017] The specific process steps are as follows:

[0018] 1) Alkali hydrolysis and precipitation reaction: After the comprehensive wastewater is measured, put it into the alkali hydrolysis reaction kettle, adjust the pH to 7.0-8.0 with lime (calcium oxide or calcium hydroxide), and stir at 90°C for 2 hours under normal pressure for alkali hydrolysis and precipitation. Precipitation reaction, followed by dehydration and separation; slag is piled up for comprehensive utilization. The clear liquid is put into the reactor again for the next step.

[0019] 2) Fenton oxidation reaction: Fenton reagent is used to carry out oxidation reaction on the wastewater after alkali hydrolysis and precipitation reaction...

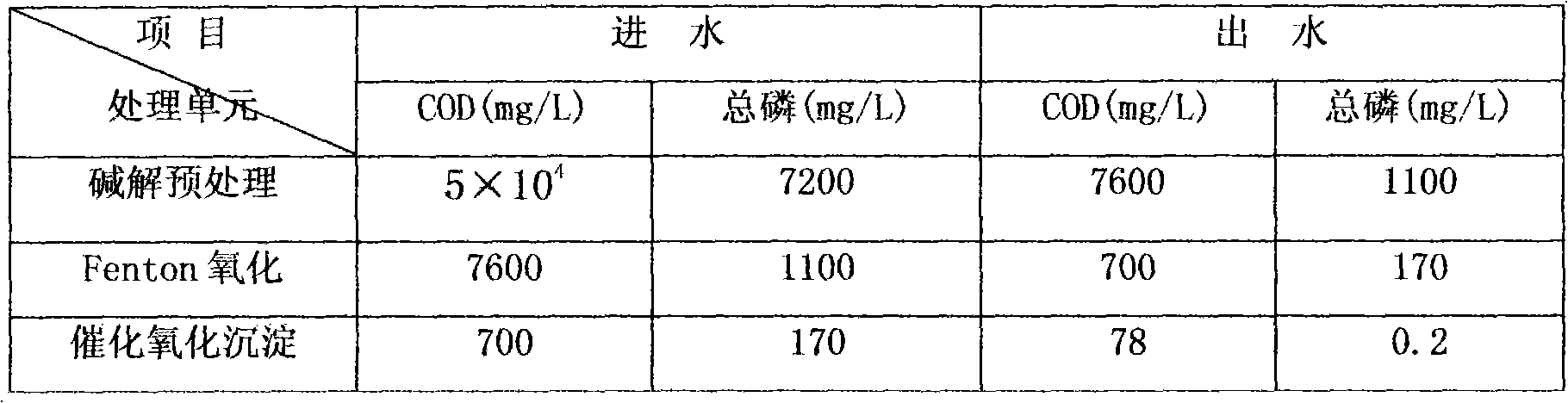

Embodiment 2

[0025] Using glyphosate wastewater from an enterprise in Guangxi as the water to be treated, the phosphorous removal treatment was carried out by using alkaline hydrolysis and precipitation reaction, Fenton oxidation reaction, and catalytic reprecipitation process.

[0026] The specific process steps are as follows:

[0027] 1) Alkali hydrolysis and precipitation reaction: After the comprehensive wastewater is measured, it is put into the alkaline hydrolysis reaction kettle, and the pH is adjusted to 7.0-8.0 with lime (calcium oxide or calcium hydroxide). Under normal pressure, stir at 70°C for 2 hours to carry out alkali hydrolysis and precipitation reaction, and then dehydrate and separate; the slag is piled up for comprehensive utilization. The clear liquid is put into the reactor again for the next step.

[0028] 2) Fenton oxidation reaction: Fenton reagent is used to carry out oxidation reaction on the wastewater after alkali hydrolysis and precipitation reaction. Throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com