Concrete pavement material with function of adsorbing and solidifying CO2 in automobile exhaust, pavement, and preparation and application methods thereof

A technology for concrete pavement and automobile exhaust, applied in the direction of chemical instruments and methods, on-site coagulation pavement, separation methods, etc., can solve the problems that have not been disclosed, achieve good water permeability, delay the trend of climate warming, The effect of excellent economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

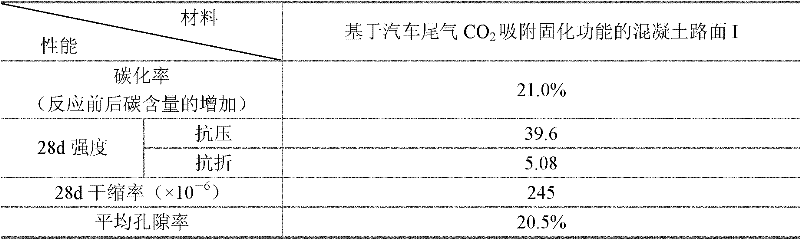

[0035] Based on vehicle exhaust CO 2 For the concrete pavement material I with adsorption and curing functions, the materials are selected according to the following mass ratios:

[0036] Cement: 60%;

[0037] Steel slag powder: 25%;

[0038] Red mud: 15%;

[0039] Basalt fiber: 1.5% by volume.

[0040] Basalt gravel: 4 times the mass of the cement-based composite cementitious material, three particle size ranges are taken respectively: 2.36-4.75mm, 4.75-9.5mm, 9.5-19.0mm.

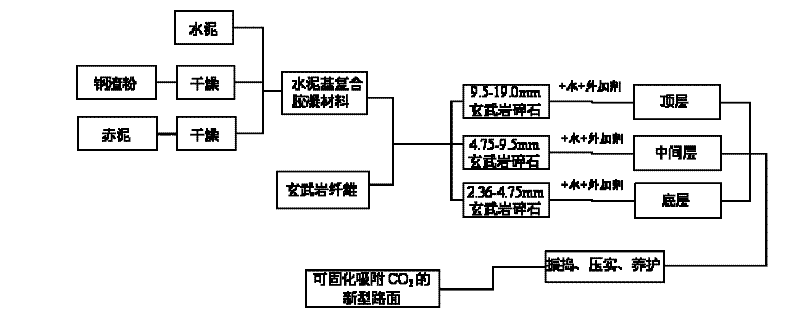

[0041] Based on vehicle exhaust CO 2 Preparation of concrete pavement I with adsorption and curing function:

[0042] (1) Mix cement, steel slag powder (dried), and red mud (dried) in proportion to obtain a cement-based composite cementitious material, and then mix and stir with basalt fiber to obtain a mixture.

[0043] (2) Mix the mixture of step (1) with basalt gravels in three particle size ranges, and add water (the amount is 0.27% of the mass of the cement-based composite cementitious material)...

Embodiment 2

[0053] Based on vehicle exhaust CO 2 For the concrete pavement material II with adsorption and curing functions, the materials are selected according to the following mass ratios:

[0054] Cement: 50%;

[0055] Steel slag powder: 30%;

[0056] Red mud: 20%;

[0057] Basalt fiber: 1.5% by volume.

[0058] Basalt gravel: 3.8 times the mass of cement-based composite cementitious materials, three particle size ranges are taken respectively: 2.36-4.75mm, 4.75-9.5mm, 9.5-19.0mm.

[0059] Based on vehicle exhaust CO 2 Preparation of concrete pavement II with adsorption and curing function:

[0060] (1) Mix cement, steel slag powder (dried), and red mud (dried) in proportion to obtain a cement-based composite cementitious material, and then mix and stir with basalt fibers to obtain a mixture.

[0061] (2) Mix the mixture of step (1) with basalt gravels in three particle size ranges respectively, and add water (the amount is 0.26 of the quality of cement-based composite cementiti...

Embodiment 3

[0071] Based on vehicle exhaust CO 2 For the concrete pavement material III with adsorption and curing functions, the materials are selected according to the following mass ratios:

[0072] Cement: 50%;

[0073] Steel slag powder: 40%;

[0074] Red mud: 10%;

[0075] Basalt fiber: 1.5% by volume.

[0076] Basalt gravel: 3.5 times the mass of cement-based composite cementitious materials, three particle size ranges are taken respectively: 2.36-4.75mm, 4.75-9.5mm, 9.5-19.0mm.

[0077] Based on vehicle exhaust CO 2 Preparation of Concrete Pavement III with Adsorption and Curing Function:

[0078] (1) Mix cement, steel slag powder (dried), and red mud (dried) in proportion to obtain a cement-based composite cementitious material, and then mix and stir with basalt fiber to obtain a mixture.

[0079] (2) Mix the mixture of step (1) with basalt gravels in three particle size ranges, and add water (the amount is 0.25 of the mass of the cement-based composite cementitious materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com