Method for promoting Eupergit C 250 to immobilize oxalate decarboxylase by using ammonium sulfate

A technology of oxalate decarboxylase and immobilized enzyme carrier, which is applied in the direction of being immobilized on/in an organic carrier, can solve the problems of increasing the cost of immobilization reaction, and achieves the benefits of recycling and reuse, improving stability, and improving immobilization. effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0020] (1) Induced expression of recombinant oxalate decarboxylase

[0021] The genetically engineered bacteria E.coli BL21(DE3) / pET32a / YvrK were inoculated in LB medium containing ampicillin (0.1mg / ml) at 37°C and cultured at 200r / min. When the bacteria grow to an OD600 of 0.4, heat shock at 42°C for 5 minutes, lower the temperature back to 37°C, and add MnCl 2 The final concentration of IPTG was 5mmol / L, and the final concentration of IPTG was 0.4mmol / L. After inducing expression for 4 hours, the bacterial pellet was collected by centrifugation, and 10mL of phosphate buffer (50mmol / L, pH8.0) was added for each gram of wet weight of the bacteria. Suspended bacteria, after the bacteria were ultrasonically disrupted, the supernatant was collected by centrifugation as a crude enzyme solution.

[0022] (2) Separation and purification of oxalate decarboxylase by affinity chromatography

[0023] Enzyme purification was performed using the AKTA-FPLC system. First, equilibrate the...

example 2

[0028] (1) Induced expression of recombinant oxalate decarboxylase is the same as example 1

[0029] (2) Affinity chromatography separation and purification of oxalate decarboxylase with example 1

[0030] (3) Immobilization of oxalate decarboxylase

[0031]EupergitC is first soaked and swollen with phosphate buffer solution, added purified oxalate decarboxylase, and ammonium sulfate to make the concentration reach 0.1-2mol / L, at pH7-10, 20-30℃, shake and immobilize at a speed of 30-200rpm 4-72h, centrifuge to discard the supernatant, add 5% mercaptoethanol to block the remaining epoxy groups, filter after 12h reaction, wash with buffer, rinse mercaptoethanol and unfixed free enzyme until there is no enzyme in the eluate Activity, that is, immobilized oxalate decarboxylase.

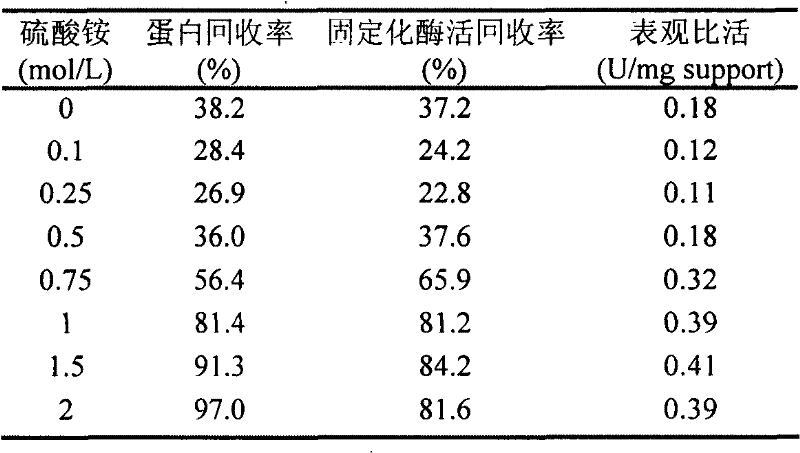

[0032] The recovery rate of protein during immobilization process, the recovery rate of immobilized enzyme activity and the apparent specific activity of immobilized enzyme are shown in Table 1.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vitality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com