Dyeing device for electrochemical reduction

A dyeing device, electrochemical technology, applied in the field of dyeing devices, can solve the problems of low current efficiency, large power consumption, long reduction time, etc., and achieve the effect of improving current efficiency and speeding up the rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

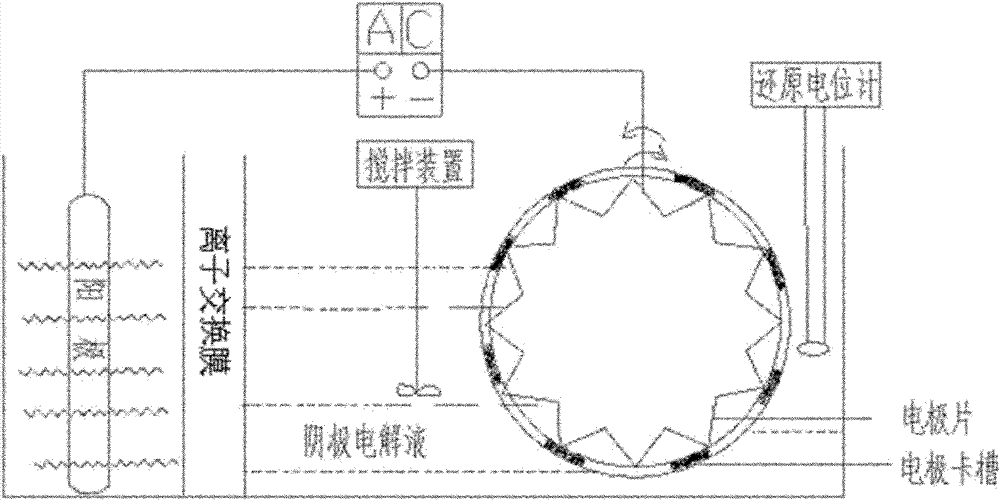

[0021] An electrochemical reduction dyeing device of the present invention comprises an anode, a centrifugal internal suction cathode and an ion exchange membrane isolating the anode from the cathode, and an anode is formed between the ion exchange membrane, the anode and the cathode area and cathode area, wherein the centrifugal internal suction cathode includes an electrode sheet and an electrode slot, the electrode sheet is a circular saw-toothed impeller, the electrode slot is circular, the electrode sheet and the electrode slot are connected to the rotating device, and Its direction of rotation is opposite. A stirring device and an electrode rod are installed in the cathode area, and the electrode rod is connected with a reduction potentiometer, which can monitor the reduction potential in the electrolyte in real time on-line to avoid excessive reduction caused by too high a reduction potential.

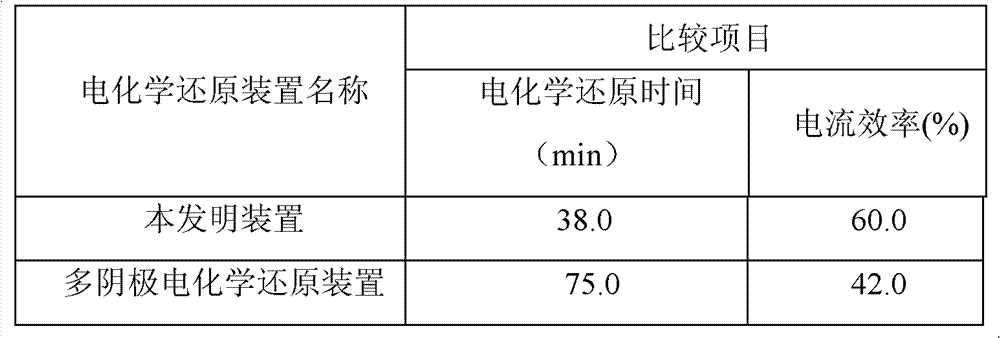

[0022] Device of the present invention and common multi-cathode electrochem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com