Separation system and separation method for oil sludge and sand

A separation system, oil sludge sand technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of different sizes of agglomerates, difficult to be washed away, noise, etc., and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

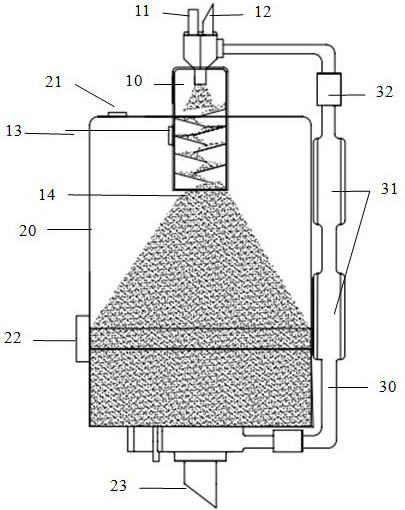

Image

Examples

Embodiment 1

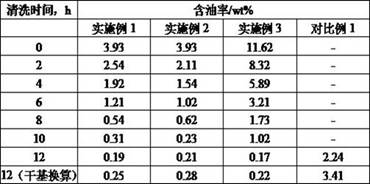

[0044] The raw materials used in this example come from the oily sludge sand separated by a three-phase separator of produced fluid in a combined station. After testing, the oily sludge sand has an oil content of 3.93wt%, a solid content of 8.21wt%, and a water content of 87.86wt% , after calculation, the oil content on dry basis is 32.37wt%.

[0045] The number of built-in interlaced sand washing plates in the gas-phase sand washing zone cylinder I is 8, the downward inclination angle is 10°, the number of mixing chambers is 2, and the number of gas-phase conveyors is 2.

[0046] According to the above process, after the smooth start-up, adjust the feed flow rate of the liquid-phase sand washing zone to 2.2m 3 / h, the outlet flow of light material is 0.8m 3 / h, the working pressure of the gas phase conveyor is 0.2MPa, and the flow rate of the compressed gas introduced is 0.6m 3 / h, start timing after stable operation for a period of time. At intervals, samples are taken fro...

Embodiment 2

[0048] The raw materials used in this example are the same as those in Example 1.

[0049] The device used in Example 2, the built-in sand washing machine sand washing plate number of the cylinder body 1 is 12, and the sand washing plate is provided with some groove V-shaped grooves, and the mixing chamber number is 3, and the gas phase conveyor number is 3.

[0050] According to the above process, after the smooth start, feed into the device, and adjust the feed flow rate in the liquid-phase sand washing area to 2.8m 3 / h, the outlet flow of light material is 0.6m 3 / h, the working pressure of the gas phase conveyor is 0.35MPa, and the flow rate of the compressed gas introduced is 0.8 m 3 / h, start timing after stable operation for a period of time. At intervals, samples are taken from the interface between the sand washing channel and the cylinder I, and from the outlet of the light material. The former is used to detect the composition of the material and compare it with t...

Embodiment 3

[0052] The raw material used in this example comes from the oily mud sand in a settling tank of a joint station. After testing, its composition is 11.62wt% oil content, 52.78wt% solid content, and 35.60wt% water content. After calculation, the oil content on a dry basis is 18.04 wt%. wt%.

[0053] The device used in Example 3, the built-in sand washing machine sand washing plate number of the cylinder body 1 is 10, the mixing chamber number is 4, and the gas phase conveyor number is 4.

[0054] According to the above process, after the smooth start-up, feed into the device, and adjust the feed flow rate in the liquid-phase sand washing area to 3.3m 3 / h, the outlet flow of light material is 0.7m 3 / h, the working pressure of the gas phase conveyor is 0.6MPa, and the flow rate of the compressed gas introduced is 0.7m 3 / h, start timing after stable operation for a period of time, at intervals, take samples from the interface between the sand washing channel and the cylinder I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com