Self-repairing antibacterial sealant and preparation method thereof

A self-healing and beautifying joint agent technology, applied in the field of coatings, can solve the problems of poor antibacterial properties and difficult repairs, and achieve the effects of keeping clean, lasting hygienic effect, good antistatic ability and bactericidal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

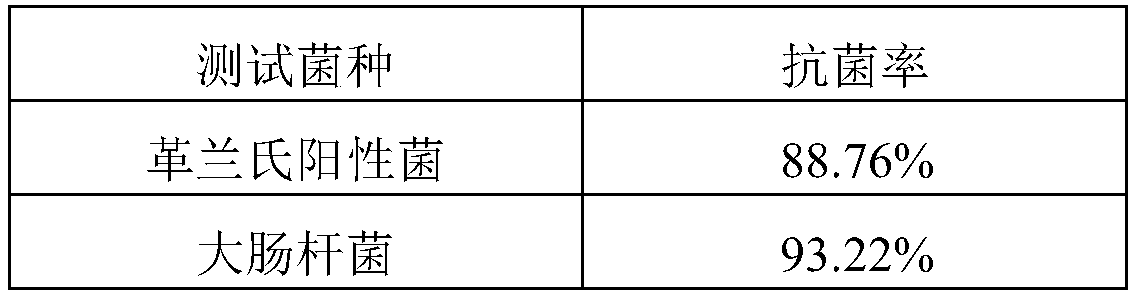

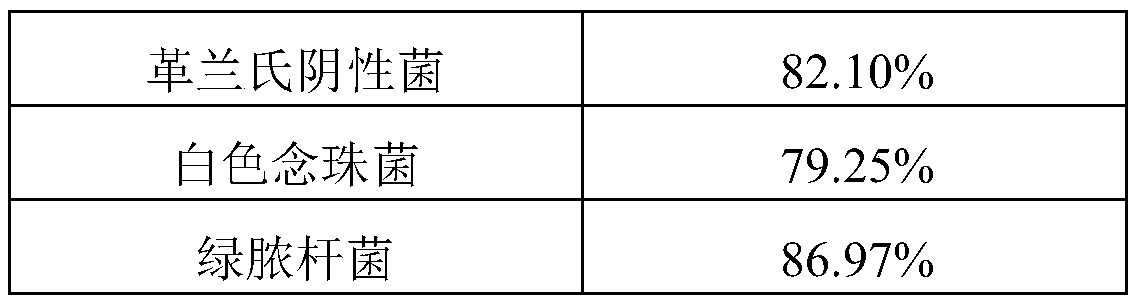

Examples

Embodiment 1

[0033] (1) A self-repairing antibacterial beautifying agent, consisting of A component and B component, said A component and B component are prepared according to the weight ratio of 1:0.8:

[0034] The A component includes the following components in parts by weight: 100 parts of epoxy resin, 2 parts of nano-titanium dioxide, 1.6 parts of silver nitrate, 0.5 parts of thixotropic agent, 0.5 parts of defoaming agent, 0.5 parts of leveling agent, and 2 parts of pigment;

[0035] The B component includes the following components in parts by weight: 60 parts of reducing agent, 0.5 part of thixotropic agent, and 1 part of curing accelerator.

[0036] The epoxy resin is epoxy resin E51.

[0037] The pigment is cadmium sulfide.

[0038] The thixotropic agent is hydroxyethyl cellulose.

[0039] The defoamer is polyoxyethylene polyoxypropylene pentaerythritol ether.

[0040] The leveling agent is 1080 of Moeneng Chemical Industry.

[0041] The reducing agent is ascorbic acid.

[0...

Embodiment 2

[0056] (1) A kind of self-repairing antibacterial beautifying seam agent, is made up of A component and B component, and described A component and B component are prepared according to weight ratio 1:1:

[0057] The A component includes the following components in parts by weight: 120 parts of epoxy resin, 6 parts of nano-titanium dioxide, 3 parts of silver nitrate, 15 parts of thixotropic agent, 1 part of defoamer, 10 parts of leveling agent, and 0.1 part of pigment;

[0058] The B component includes the following components in parts by weight: 40 parts of reducing agent, 15 parts of thixotropic agent, and 5 parts of curing accelerator.

[0059] The epoxy resin is epoxy resin E44.

[0060] The pigment is cobalt oxide.

[0061] Described thixotropic agent is polyvinyl alcohol.

[0062] The defoamer is polyoxyethylene polyoxypropanolamine ether.

[0063] The leveling agent is 1090 of Moeneng Chemical Industry.

[0064] The reducing agent hydrazine hydrate.

[0065] The cur...

Embodiment 3

[0077] (1) A kind of self-repairing antibacterial beautifying seam agent, is made up of A component and B component, and described A component and B component are prepared according to weight ratio 1:0.7:

[0078] The A component includes the following components in parts by weight: 110 parts of epoxy resin, 6 parts of nano-titanium dioxide, 3 parts of silver nitrate, 10 parts of thixotropic agent, 10 parts of defoamer, 5 parts of leveling agent, and 5 parts of pigment;

[0079] The B component includes the following components in parts by weight: 30 parts of reducing agent, 2 parts of thixotropic agent, and 10 parts of curing accelerator.

[0080] The epoxy resin is epoxy resin E51.

[0081] The pigment is carbon black.

[0082] The thixotropic agent is a mixture of hydroxyethyl cellulose and polyvinyl alcohol, wherein the mass fraction of hydroxyethyl cellulose in the mixture is 55%.

[0083] The defoamer is a mixture of polyoxyethylene polyoxypropylene pentaerythritol eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com