Electroconductive plastic master batch as well as preparation method and application thereof

A conductive plastic and masterbatch technology, applied in the field of plastic masterbatch, can solve the problems of high filter pressure, easy to pollute the production environment, and high production costs, so as to increase the probability of mutual contact, improve the weak antistatic performance, and improve the contact. The effect of chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

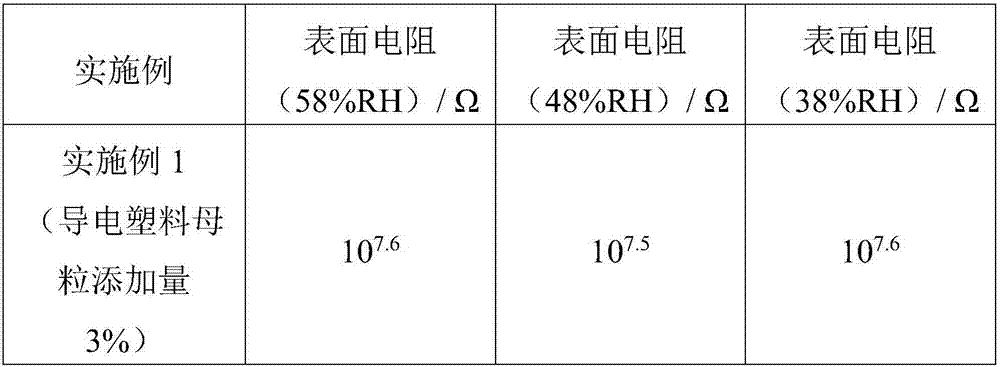

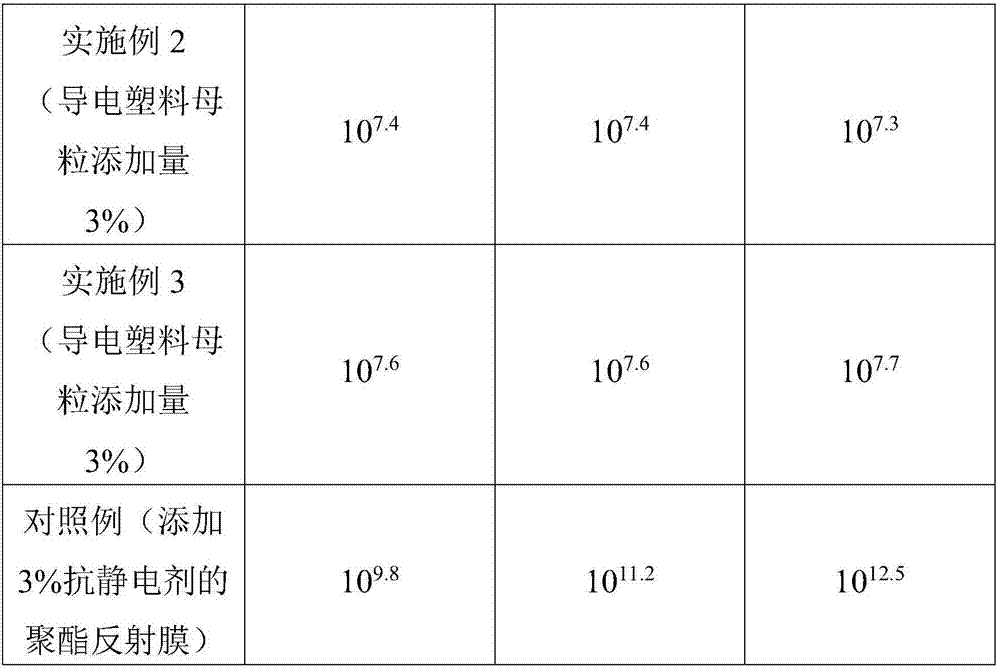

Examples

Embodiment 1

[0027] A kind of conductive plastic masterbatch, its component formula is as follows:

[0028] Polyester resin (PET film grade chips produced by China Yizheng Chemical Fiber Co., Ltd., the brand name is FG620) 45kg

[0030] Triethanolamine 0.5kg

[0032] Sorbitan Fatty Acid Ester 3kg

[0033] Diphenylamine 0.5kg

[0034] Dicumyl Hydroperoxide 0.3kg

[0035] The preparation method of this conductive plastic masterbatch comprises the following steps:

[0036] (1) Nickel sulfate, triethanolamine, sodium carbonate, sorbitan fatty acid ester, diphenylamine, and dicumyl hydrogen peroxide are weighed into a high-speed mixer and mixed evenly, and then sliced with polyester resin Add it into the twin-screw extruder for full mixing by weight loss, and homogenize to obtain a molten mixture. The processing temperature of the twin-screw extruder is 270°C, and the screw speed is 500r / min;

[0037] (2) The molten mixture in...

Embodiment 2

[0040] A kind of conductive plastic masterbatch, its component formula is as follows:

[0041] Polyester resin (PET film grade chips produced by China Yizheng Chemical Fiber Co., Ltd., the brand name is FG620) 40kg

[0043] N-Methyldiethanolamine 0.1kg

[0044] Magnesium carbonate 1kg

[0045] Polyoxyethylene fatty acid ester 2kg

[0046] p-Phenylenediamine 0.5kg

[0047] Benzoyl peroxide 0.8kg

[0048] The preparation method of this conductive plastic masterbatch comprises the following steps:

[0049] (1) Copper sulfate, N-methyldiethanolamine, magnesium carbonate, polyoxyethylene fatty acid ester, p-phenylenediamine, and benzoyl peroxide are put into a high-speed mixer and mixed evenly with poly The ester resin chips are added to the twin-screw extruder through a weight loss scale for full mixing, and homogenized to obtain a molten mixture. The processing temperature of the twin-screw extruder is 275°C, and the screw speed is 400r / min;

...

Embodiment 3

[0053] A kind of conductive plastic masterbatch, its component formula is as follows:

[0054] Polyester resin (PET film grade chips produced by China Yizheng Chemical Fiber Co., Ltd., the brand name is FG620) 50kg

[0055] Nickel sulfate 0.2kg

[0056] 1-Dimethylamino-2-propanol 1kg

[0057] Sodium bicarbonate 5kg

[0058] Polyoxyethylene amide 5kg

[0059] Dihydroquinoline 0.9kg

[0060] Dicumyl peroxide 1.0kg

[0061] The preparation method of this conductive plastic masterbatch comprises the following steps:

[0062] (1) Nickel sulfate, 1-dimethylamino-2-propanol, sodium bicarbonate, polyoxyethylene amide, dihydroquinoline, and dicumyl peroxide are weighed into a high-speed mixer and mixed homogeneous, then add polyester resin chips into a twin-screw extruder through a weight loss scale for full mixing, and homogenize to obtain a molten mixture. The processing temperature of the twin-screw extruder is 265 ° C, and the screw speed is 300r / min;

[0063] (2) The molt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com