Passive wireless surface acoustic wave stress sensor adopting three-layer stress transferring model

A stress sensor, surface acoustic wave technology, applied in the direction of force measurement by measuring the frequency change of a stressed vibrating element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention is described in detail below:

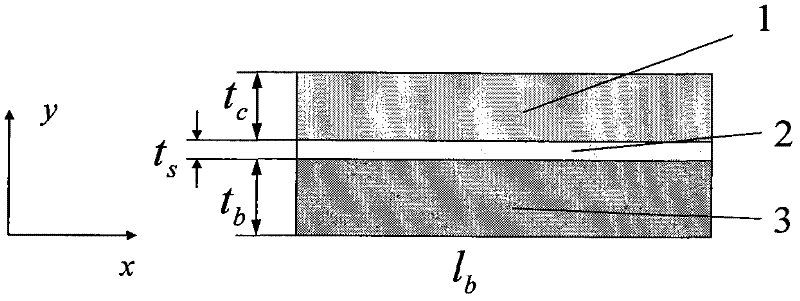

[0021] figure 1 In the present invention, the surface acoustic wave resonator 1 is pasted on the surface of the subject material 3 to be tested through an epoxy adhesive 2 . Under the action of external force, the two ends of the main structure material 3 bear the tensile force, while the two ends and the free surface of the sensor layer 1 and the adhesive layer 2 have no external stress. The two ends of the sensor layer 1 and the adhesive layer 2 are not stressed, but the shear stress at the interface between the three layers transfers the axial stress of the structural material layer 3 to the adhesive layer 2 and the sensor layer 1, so that the SAW resonator also bears Axial stress.

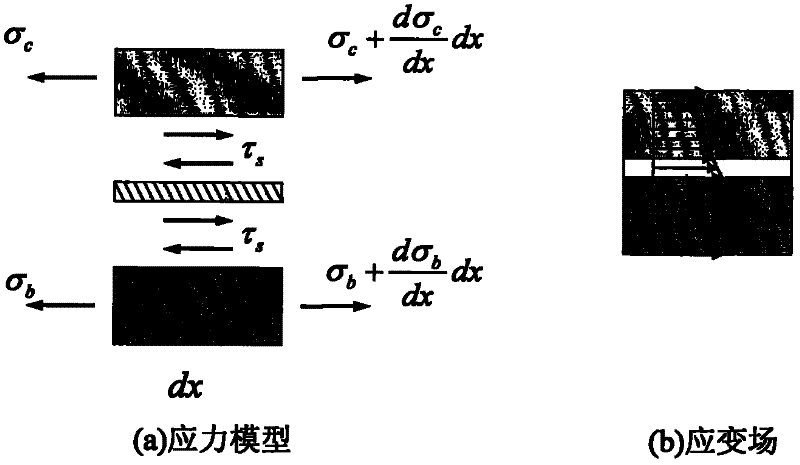

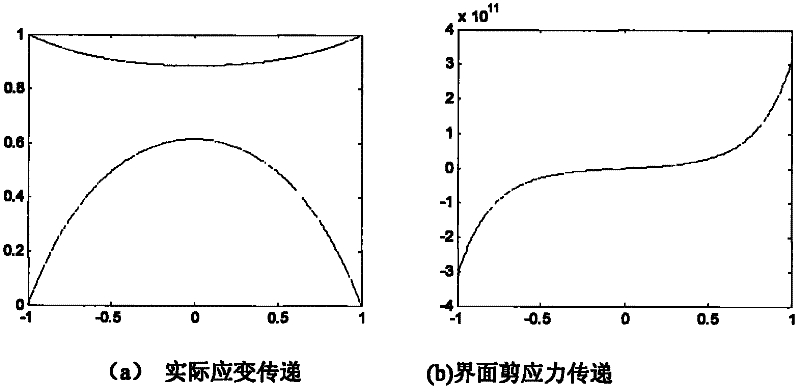

[0022] Reflecting the problem of strain transfer in the structure, a three-layer model can be established and the mechanism of strain transfer can be analyzed using the shear hysteresis theory, which are: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com