System for testing vibration attenuation of suspension of rail vehicle

A vibration attenuation and rail vehicle technology, which is applied in vibration testing, railway vehicle testing, machine/structural component testing, etc., can solve the problems of high cost and complex structure of the test bench, and achieve good safety, structural integrity, and positioning quick effect

Inactive Publication Date: 2011-09-07

JILIN UNIV

View PDF5 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Among them, the electro-hydraulic servo test bench has better performance. This kind of test bench can simulate the road spectrum of the complex vehicle operating environment through closed-loop control. The test bench continuously excites the vehicle through the hydraulic cylinder, and stops when the vibration of the vehicle reaches a certain level. Vibration, measuring the displacement or acceleration attenuation characteristics of the vehicle to evaluate the quality of the vehicle suspension, this test result is closer to the actual situation, but this kind of test bench has high cost, complex structure, and needs special manufacturing. At present, almost all of them are imported in China. Such products abroad

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

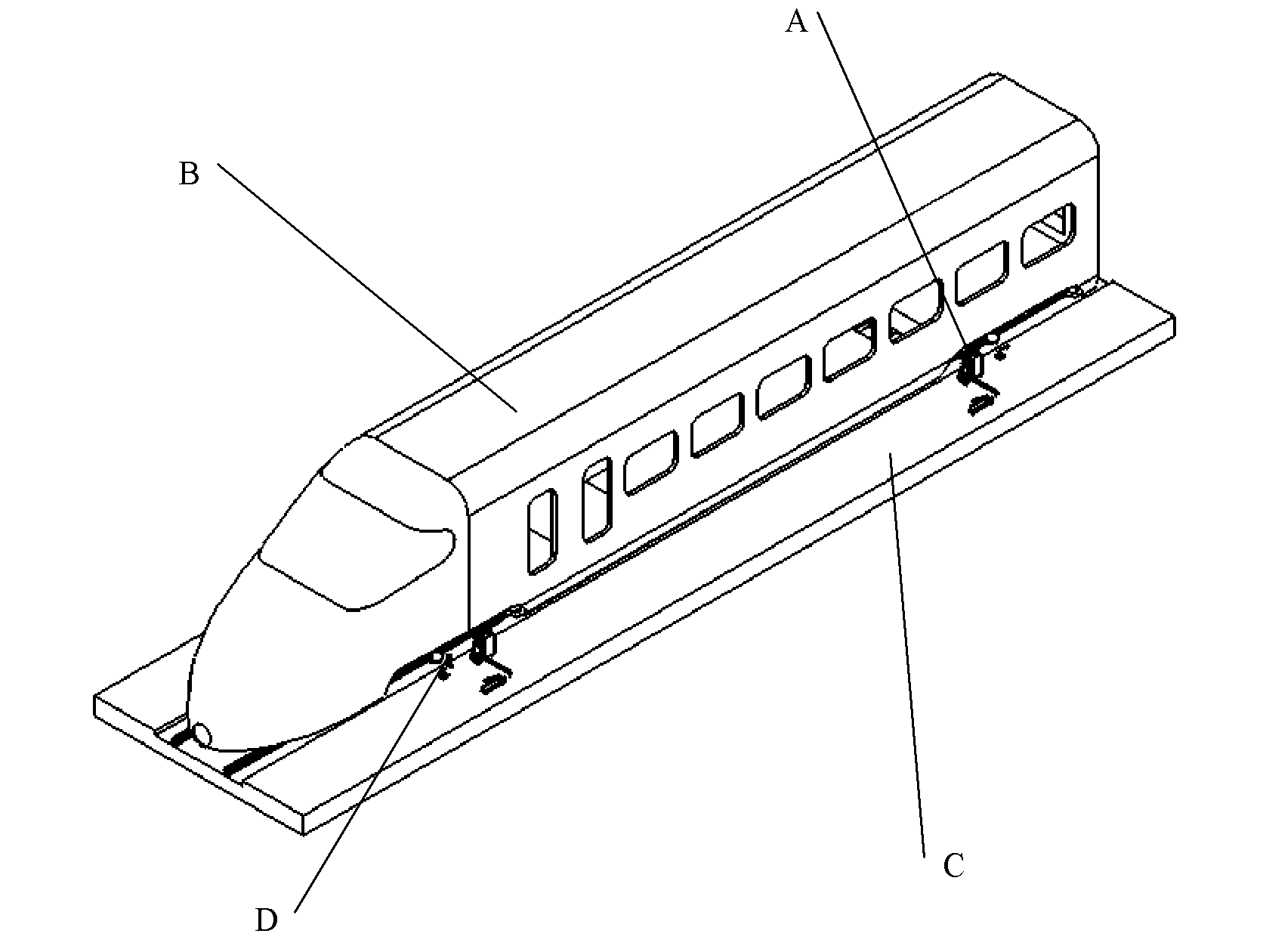

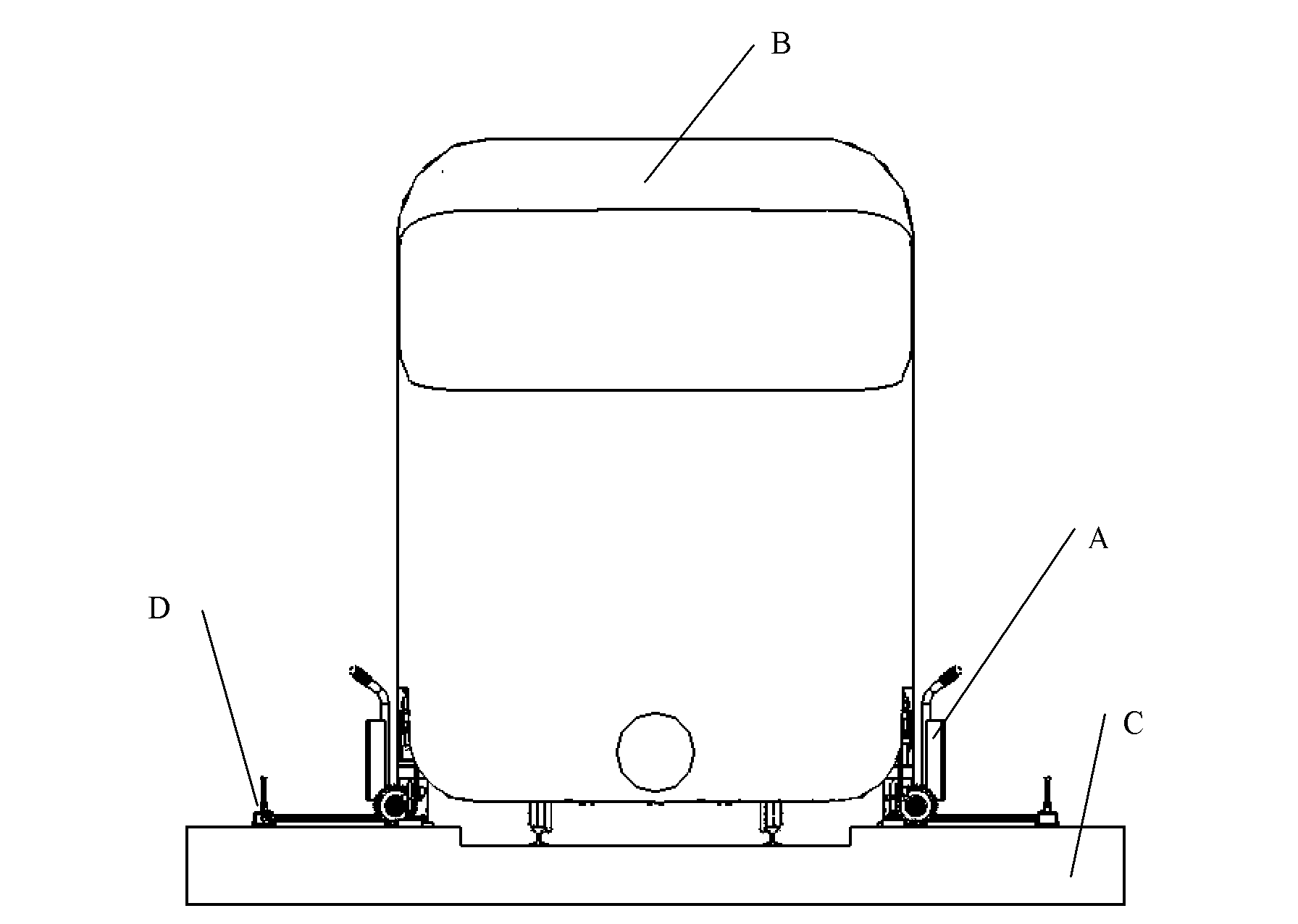

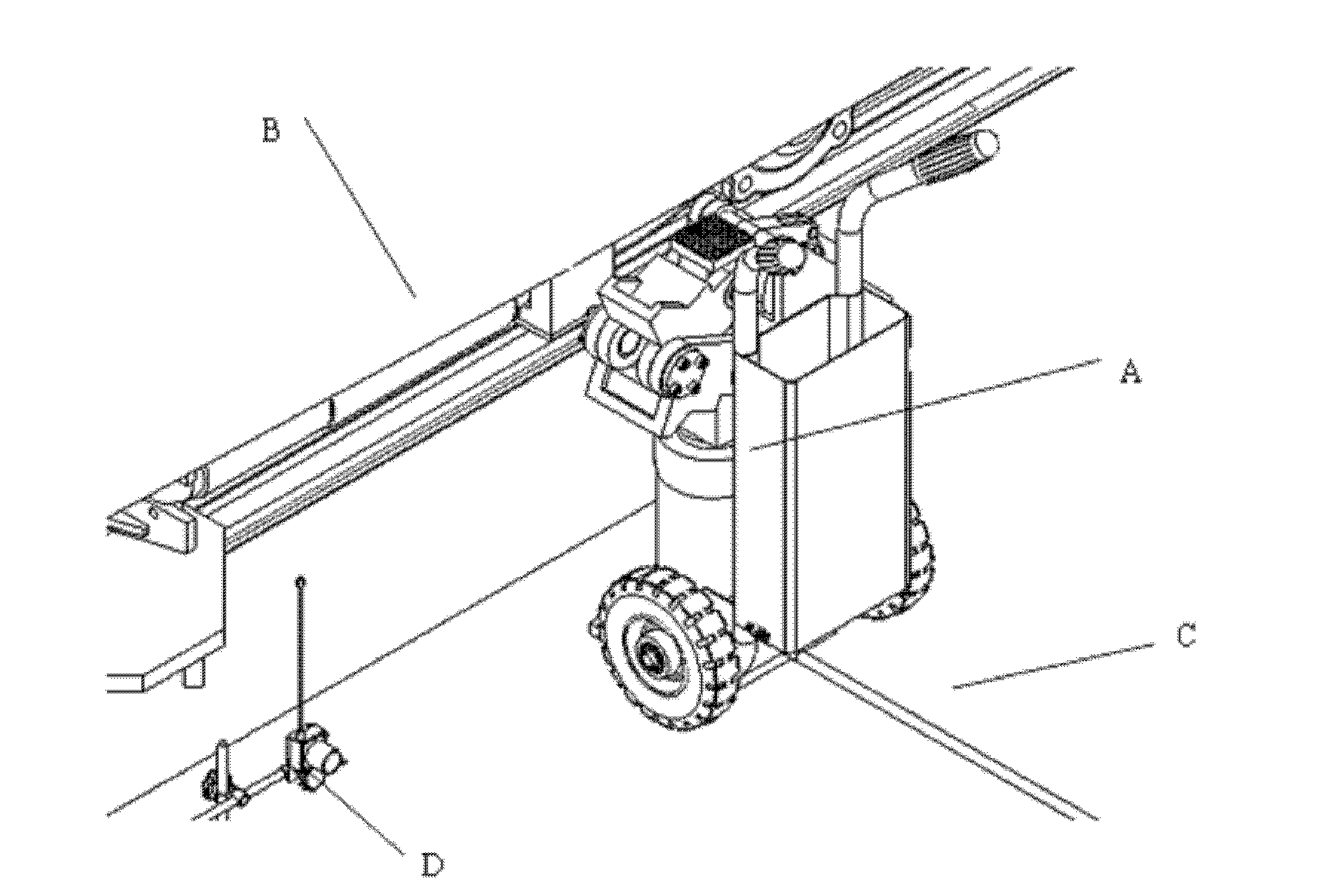

The invention relates to a system for testing vibration attenuation of a suspension of a rail vehicle, and belongs to parameter detection equipment of a rail vehicle. The system is designed to meet the requirement for detection of vibration attenuation characteristics of a rail vehicle. The system consists of mobile quick-falling release lifting devices, a China railways high-speed (CRH) bullet train, a falling test ground and rail device and a test system. The mobile quick-falling release lifting device comprises a falling arm assembly, a jack , a manual oil pump and a mobile vehicle; the CRH bullet train comprises a CRH bullet train body, a windshield and a bogie assembly; the falling test ground and rail device mainly comprises a falling test ground and a falling test rail; and the test system comprises a displacement detection system and an acceleration detection system, wherein the displacement detection system consists of a drawing wire encoder, a magnetic stand and a magnetic stand fixed steel plate, and the acceleration detection system consists of an acceleration sensor.

Description

Technical field The invention relates to a rail vehicle parameter detection device, in particular to a rail vehicle suspension vibration attenuation test system. Background technique Suspension is the general term for all power transmission coupling devices between the frame and the wheels. The function of the suspension is to transfer the various forces and moments exerted by the track on the wheels to the frame, absorbing and alleviating the impact and vibration transmitted to the frame due to wheel bounce caused by uneven road surface during driving. Suspension is one of the important components of bogies. It must have good damping characteristics to ease the interaction between the vehicle and the line, reduce vibration and impact, and improve the stability, safety and reliability of vehicle operation. The vibration attenuation characteristics of rail vehicle suspensions will also directly affect the stability of vehicle handling and ride comfort. Therefore, vehicles in us...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M17/10G01M7/02

Inventor 苏建刘洪发王金田张立斌谭富星宫海彬张栋林曹跃刘玉梅潘洪达陈熔戴建国徐观林慧英

Owner JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com