Method for preparing banana juice

A banana juice and banana technology, applied in the direction of food science, etc., can solve the problems of low juice yield, low content, unfavorable industrial production, etc., and achieve the effect of easier preservation, high stability, and improved juice yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

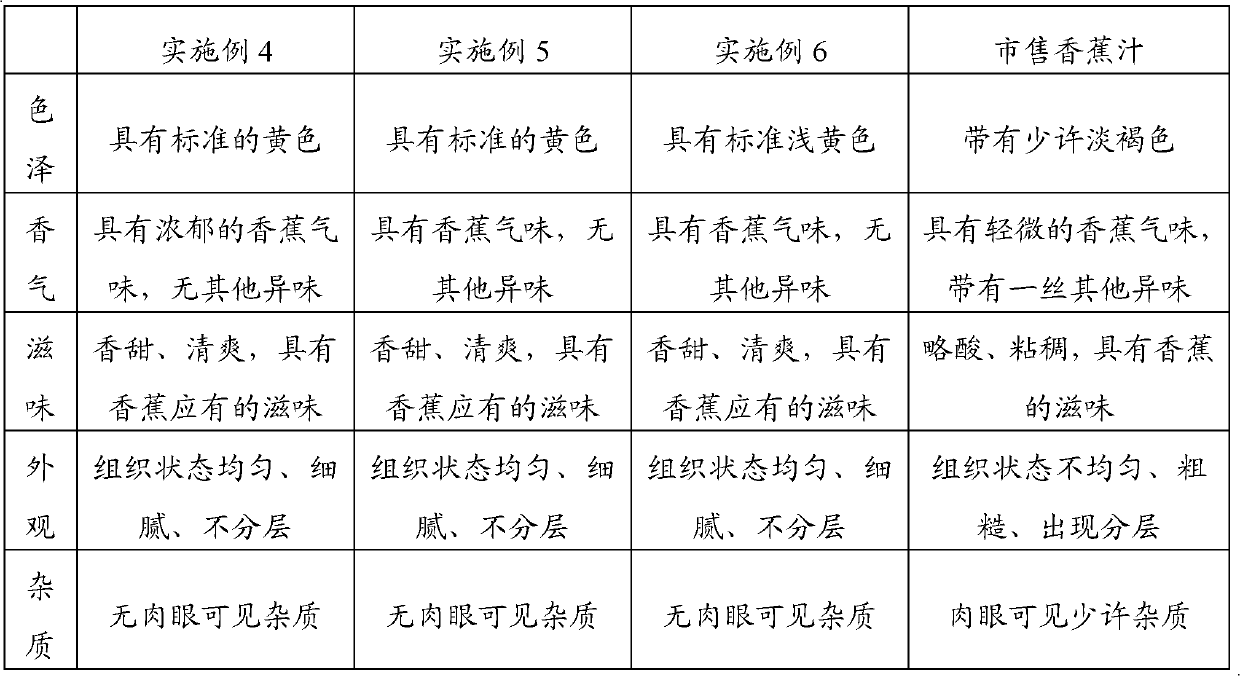

Examples

preparation example Construction

[0021] The invention discloses a method for preparing banana juice, and those skilled in the art can refer to the content of this article and appropriately improve the process parameters to realize it. In particular, it should be pointed out that all similar replacements and modifications are obvious to those skilled in the art, and they are all considered to be included in the present invention. The method of the present invention has been described through preferred embodiments, and relevant personnel can obviously make changes or appropriate changes and combinations to the methods and applications described herein without departing from the content, spirit and scope of the present invention to realize and apply The technology of the present invention.

[0022] The preparation method of a kind of banana juice provided by the present invention will be further described below.

Embodiment 1

[0023] Embodiment 1: produce banana juice with preparation method of the present invention

[0024] Take unrotten ripe bananas, clean and peel them, weigh 10kg of banana pulp, slice the banana pulp, and scald it with hot water at 100°C for 2.5 minutes; dissolve 25g of citric acid and 15g of cysteine in an appropriate amount of warm water to prepare The color-protecting solution is used for standby; the sliced pulp is crushed, and the ratio of the pulp and the color-protecting solution is 1:1, and the color-protecting solution is added while crushing, and the obtained broken pulp is used for subsequent use;

[0025] Heat the crushed pulp to about 90°C, keep the temperature for 30 seconds to inactivate the oxidase, immediately cool it with water, and beat the enzyme-inactivated pulp for 2 minutes to obtain a slurry for later use;

[0026] Keep the temperature of the slurry at about 45°C in a constant temperature water bath, adjust the pH to about 4.6 with 20% (W%) phosphoric...

Embodiment 2

[0034] Embodiment 2: produce banana juice with preparation method of the present invention

[0035] Take unrotten ripe bananas, clean and peel them, weigh 10kg of banana pulp, slice the banana pulp, and scald it with hot water at 100°C for 2.5 minutes; dissolve 25g of citric acid and 15g of cysteine in an appropriate amount of warm water to prepare The color-protecting solution is used for standby; the sliced pulp is crushed, and the ratio of the pulp and the color-protecting solution is 1:1, and the color-protecting solution is added while crushing, and the obtained broken pulp is used for subsequent use;

[0036] Heat the crushed pulp to about 90°C, keep the temperature for 30 seconds to inactivate the oxidase, immediately cool it with water, and beat the enzyme-inactivated pulp for 2 minutes to obtain a slurry for later use;

[0037]Keep the temperature of the slurry at about 45°C in a constant temperature water bath, adjust the pH to about 4.6 with 20% (W%) phosphoric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com