Nondestructive detecting and screening method based on near-infrared for crop single-grain components

A screening method and non-destructive testing technology, applied in sorting, color/spectral characteristic measurement, etc., can solve problems such as high-throughput non-destructive single-grain detection and sorting methods that have not been reported yet, achieve intuitive variety identification and improve resolution efficiency, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

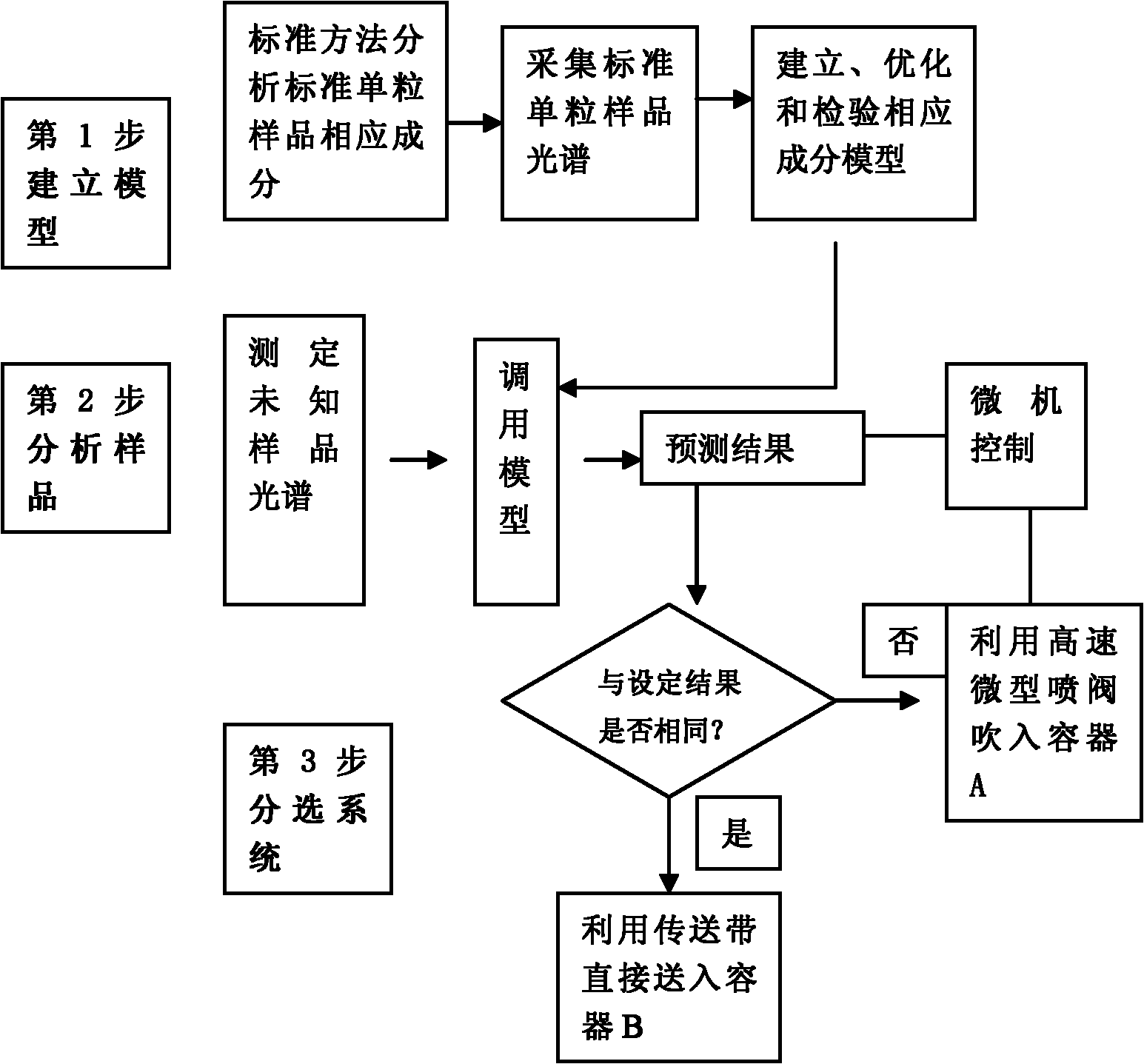

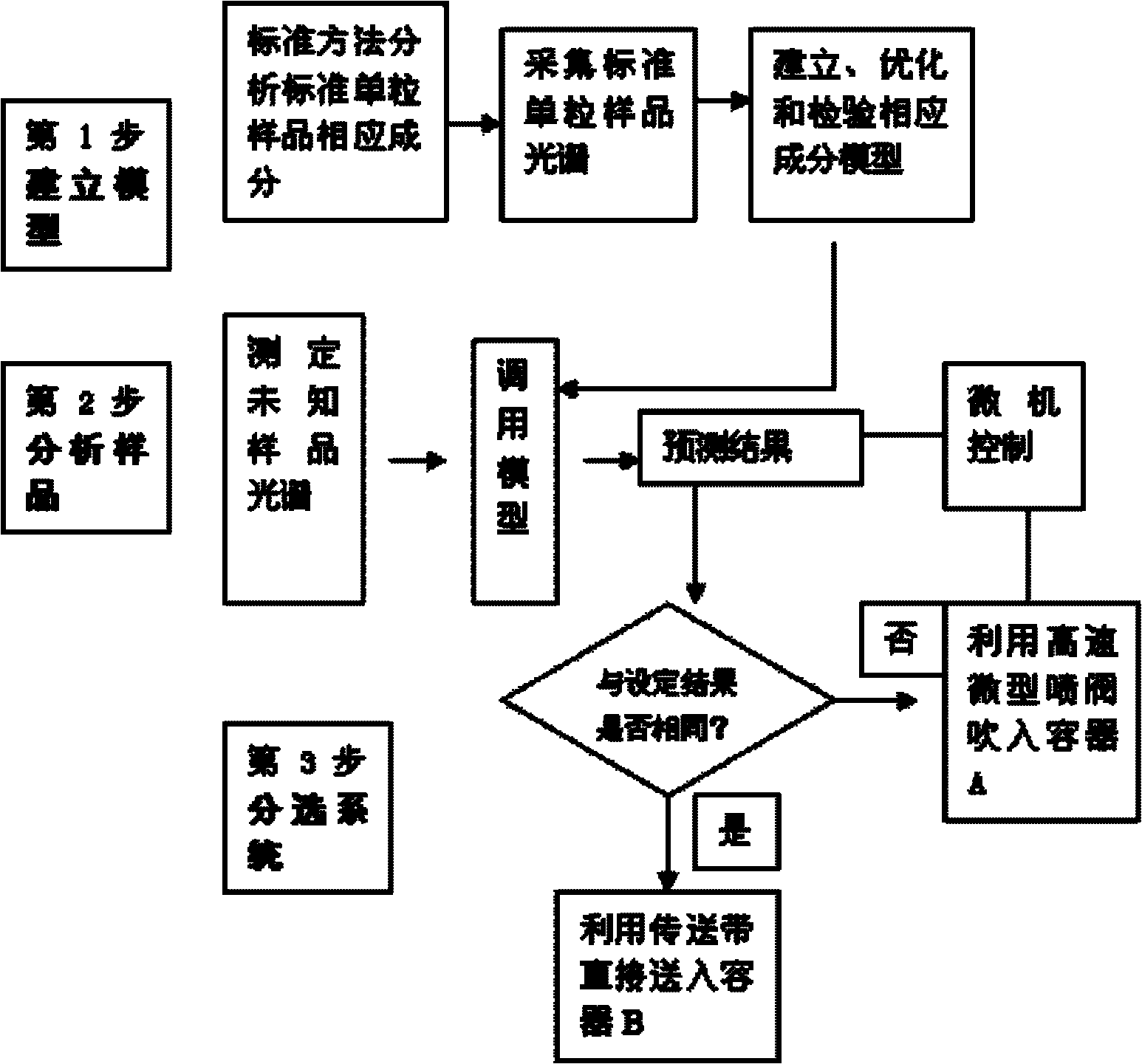

Method used

Image

Examples

Embodiment Construction

[0038] First, the peripherals are powered on, the computer is controlled to start up, the system control unit is started, and the near-infrared nondestructive testing system, the transport unit and the sorting unit are initialized. After the initialization is completed, the seed delivery unit of the system arranges the seeds to be detected on the conveyor belt neatly, and the conveyor belt moves the first seed to the near-infrared detection unit to obtain its corresponding near-infrared spectrum. Then compare the map with the standard model library established in the early stage to judge whether it meets the requirements. After that, the conveyor belt continues to move forward, passing the next seed to the near-infrared detection unit, while the already detected seeds are sent to the sorting unit. If the requirements are not met, the seeds will be blown into a receiving container A by the high-speed airflow ejected by a special high-speed micro spray valve, otherwise, the seed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com