Dry powder mortar as well as experiment and preparation methods thereof

A technology of dry powder mortar and fly ash, which is applied in the field of dry powder mortar and its experiment and preparation, can solve the problem of preparing dry powder mortar without precedent, and achieve the effect of increasing added value and huge social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

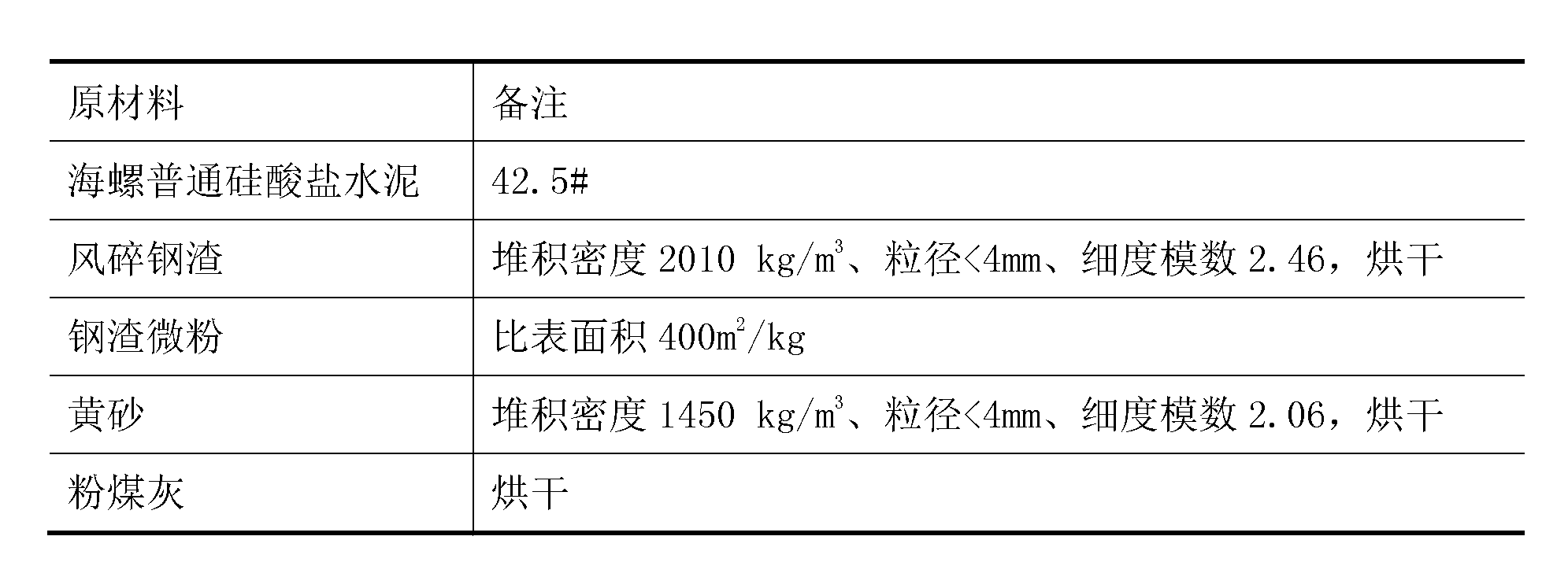

[0026] The present invention is described in detail below, which is a preferred embodiment among various implementations of the present invention.

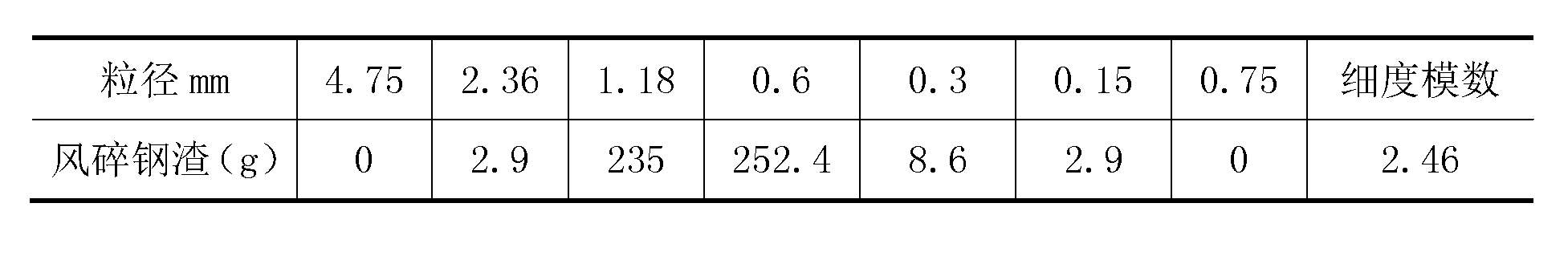

[0027] Wind-crushed steel slag has a hard appearance, dense structure and high hardness. The particle size distribution and fineness modulus of the particle size below 4mm are as follows:

[0028]

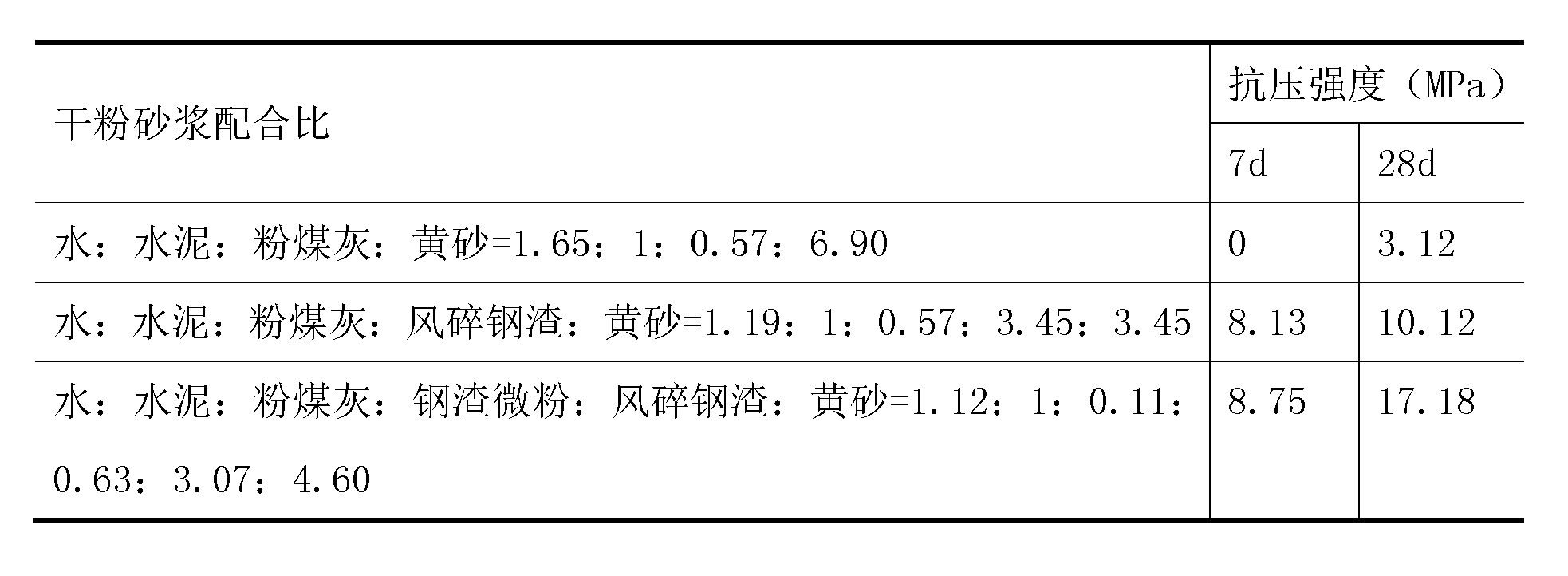

[0029] According to its own characteristic of wind crushed steel slag, it is used to replace yellow sand in a large amount, and the steel slag fine powder is partially replaced by cement to prepare dry powder mortar for masonry. The determination of the mortar mix ratio refers to JGJ98-2000 "Design Rules for Masonry Mortar Mix Ratio", and its performance test refers to JGJ70-1990 "Basic Performance Experimental Method of Building Mortar".

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com