Barium zirconate proton conductor with multi-phase structure and preparation method thereof

A proton conductor and phase structure technology is applied in the field of ceramic materials to achieve the effects of enhancing interfacial proton conduction, low cost and increasing proton migration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

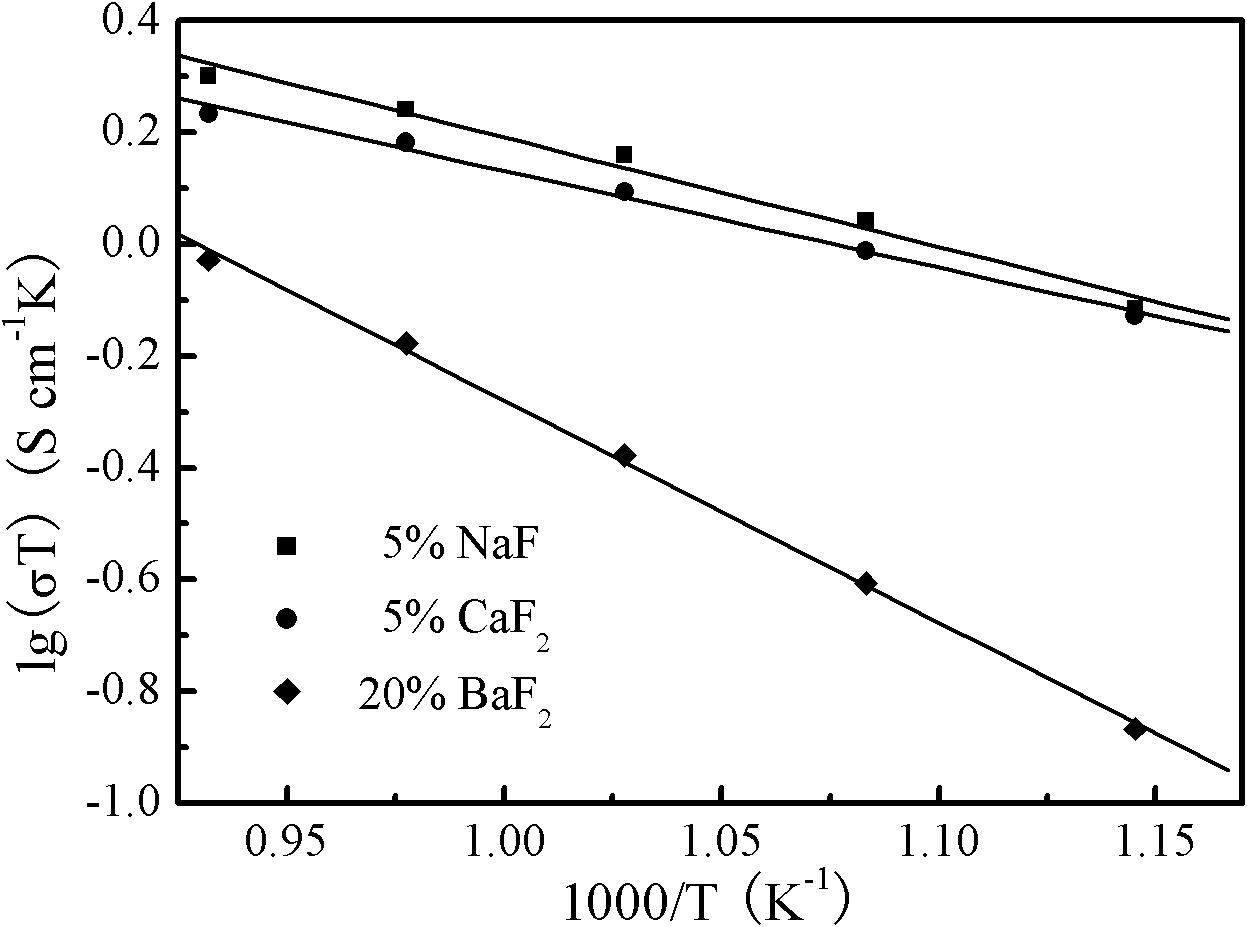

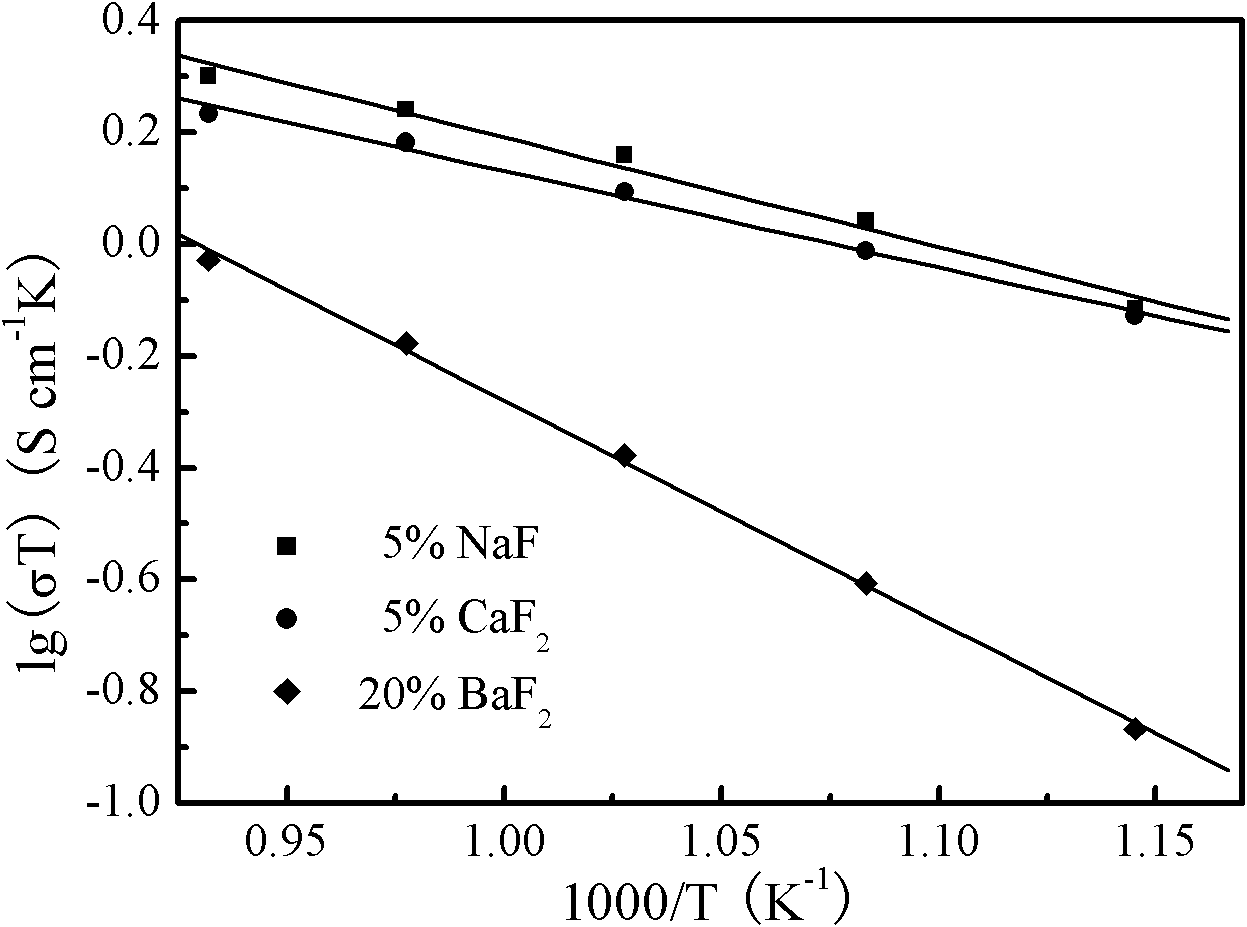

[0014] Take 1 mole of BaCO 3 , 1 mole of ZrO 2 , 0.13 mol Sc 2 o 3 , mixed with water for 4 hours by ball milling, dried, ground, sieved, and calcined at 1200 for 12 hours to obtain Sc 2 o 3 doped BaZrO 3 Matrix material. Then based on the base material, add 0.02 mole of ZnO, ball mill and mix for 4 hours, then dry, grind, and sieve, then base on the base material, add 0.05 mole of NaF, and grind for 1 hour to ensure the uniformity of the mixture. The mixture was put into a mold for dry pressing at a pressure of 50 MPa, and then subjected to isostatic pressing at 200 MPa; sintered at 1200 °C in an air atmosphere with a heating rate of 2 °C / min, kept for 10 hours, and then naturally cooled to room temperature to obtain Barium zirconate proton conductor material with good conductivity, the conductivity reaches 2.90×10 at 800°C -3 S / cm.

Embodiment 2

[0016] Take 1 mole of BaCO 3 , 1 mole of ZrO 2 , 0.30 mole Sc 2 o 3 The base material was prepared, and the base material was obtained by ball milling with water as the medium for 10 hours, drying, grinding, sieving, and calcining at 1400°C for 4 hours. Then add 0.10 mole of ZnO, ball mill and mix for 10 hours, then dry, grind and sieve, then add 0.50 mole of NaF (based on 1 mole of matrix material), and mill for 1 hour to ensure the uniformity of the mixture. The mixture was put into a mold for dry pressing at a pressure of 120 MPa, and then subjected to isostatic pressing at 350 MPa; sintered at 1500 °C in an air atmosphere, with a heating rate of 10 °C / min, kept for 2 hours, and then naturally cooled to room temperature to obtain Barium zirconate proton conductor material with good electrical conductivity.

Embodiment 3

[0018] Take 1 mole of BaCO 3 , 1 mole of ZrO 2 , 0.13 mol Sc 2 o 3 , using water as the medium for ball milling and mixing for 6 hours, drying, grinding, sieving, and calcining at 1400 for 6 hours to obtain the matrix material. Then add 0.02 moles of ZnO, ball mill and mix for 6 hours, then dry, grind and sieve, and then add 0.10 moles of CaF 2 (Based on 1 mole of base material), grind for 1 hour to ensure the homogeneity of the mixture. Put the mixture into a mold for dry pressing at a pressure of 120MPa, and then undergo isostatic pressing at 200MPa; sinter at 1350°C in an air atmosphere with a heating rate of 2°C / min, keep it warm for 4 hours, and then naturally cool to room temperature to obtain High conductivity barium zirconate proton conductor material, the conductivity reaches 1.94×10 at 800°C -3 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com