Spray drier

A technology of spray dryer and sprayer, which is applied in the field of spray dryer, and can solve the problems that the precision and dispersibility of malt paste cannot meet the new requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

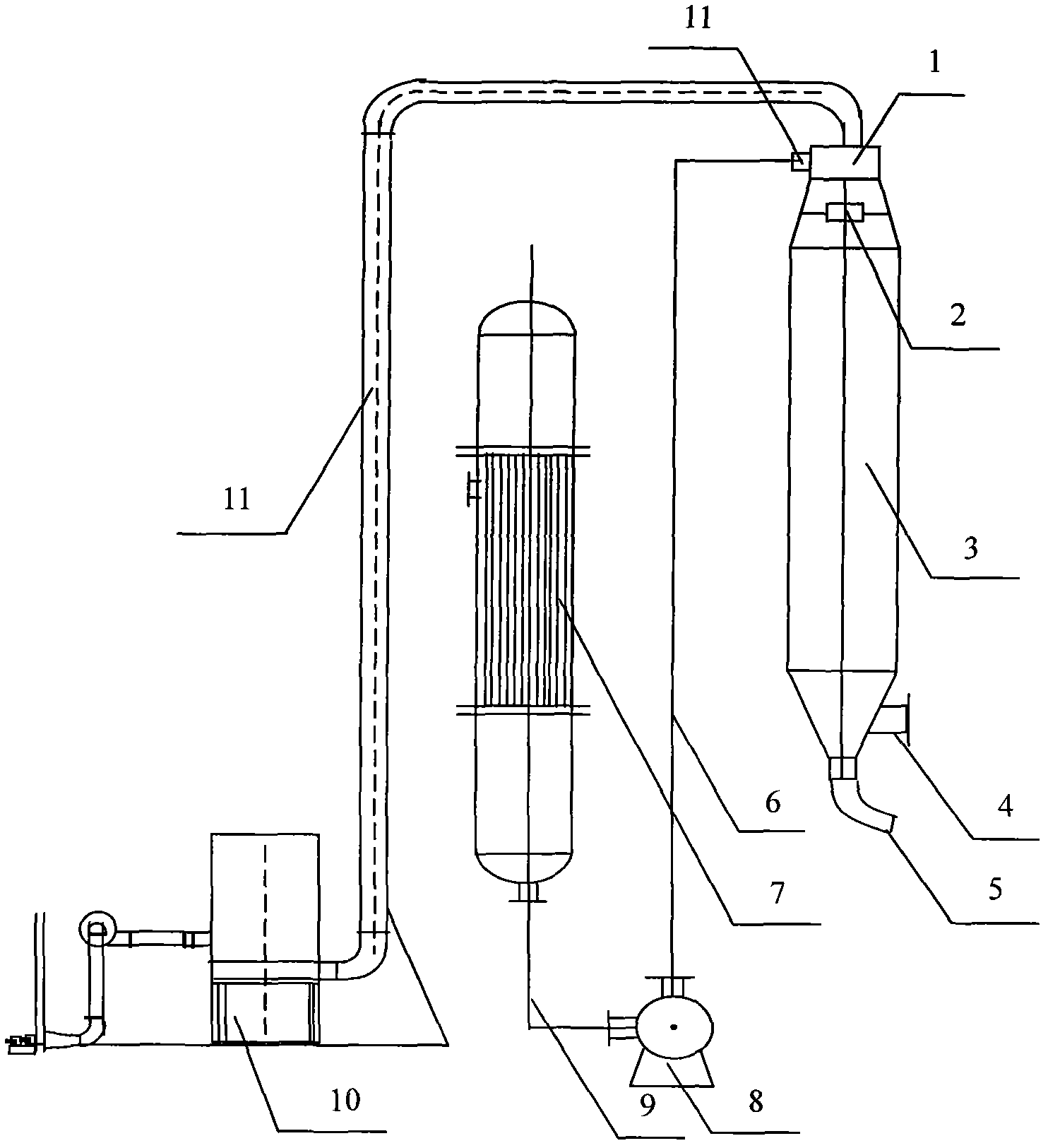

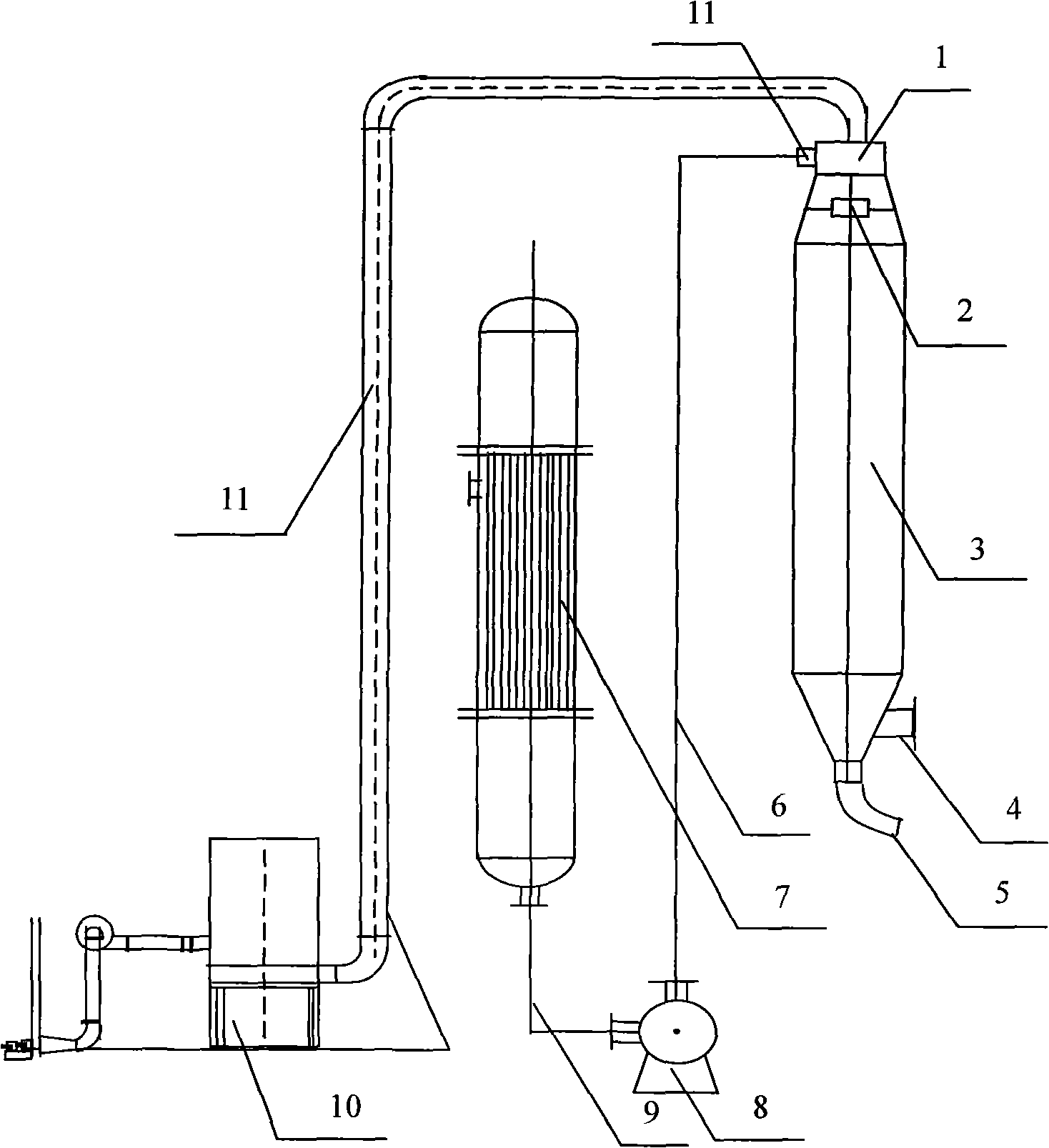

[0018] As shown in the figure, the spray dryer includes a gas heater 10, a drying tower 3, a heat distributor 1 and a sprayer 1. The gas heater 10 communicates with the heat distributor 1 at the top of the drying tower 3 through a hot air pipe 11, and the sprayer 2 is installed on The inner upper part of the drying tower 3 is dried. The spray dryer also includes a tube heater 7 , the tube heater 7 communicates with the feed pump 8 through the feed pipe 9 , and the feed pump 8 communicates with the feed port 12 of the drying tower 3 through the feed pipe 6 . The nozzle of the sprayer 3 is a spiral nozzle.

[0019] The specific process steps for preparing maltodextrin are as follows:

[0020] (1) Sizing: Use 45°C hot water to adjust starch milk with a mass percentage concentration of 25%, pH = 3, add α-high temperature amylase, and stir at 0.30Kg / t to make the slurry fluidity in good condition;

[0021] (2) Injection liquefaction: use a low-pressure injector with material and...

Embodiment 2

[0026] The spray dryer used was the same as that used in Example 1.

[0027] The specific process steps for preparing maltodextrin are as follows:

[0028] (1) Sizing: use 55°C hot water to adjust the starch milk with a mass percentage concentration of 40%, pH = 5, add α-high temperature amylase, the amount of enzyme added is 0.40Kg / t, stir to make the slurry flow sex is in good condition;

[0029] (2) Injection liquefaction: adopt a low-pressure injector with material and gas, the material pressure is 0.3mPa, the steam pressure is 0.6mPa, the first injection temperature is 110°C, and the injection time is 12min. After the first injection, maintain 95°C for 90min and control The DE value is 20%, the second injection temperature is 135°C, and the injection time is 5 minutes;

[0030] (3) Microporous refining: After the second injection, cool the liquefied liquid to below 90°C, add activated carbon with a mass percentage of 1% to stir and adsorb for 30 minutes, and filter thro...

Embodiment 3

[0034] The spray dryer used was the same as that used in Example 1.

[0035] The specific process steps for preparing maltodextrin are as follows:

[0036] (1) Sizing: Use 48°C hot water to adjust starch milk with a mass percentage concentration of 30%, pH=4, add α-high temperature amylase, and stir at 0.35Kg / t to make the slurry fluidity in good condition;

[0037] (2) Injection liquefaction: use a low-pressure injector with material and gas, the material pressure is 0.3mPa, the steam pressure is 0.6mPa, the first injection temperature is 107°C, and the injection time is 10min. After the first injection, maintain 95°C for 70min and control The DE value is 18%, the second injection temperature is 135°C, and the injection time is 5 minutes;

[0038] (3) Microporous refinement: After the second injection, cool the liquefied liquid to below 90°C, add activated carbon with a mass percentage of 1% to stir and adsorb for 30 minutes, and filter through a microporous filter to remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com