Application of carboxylic acid metal salt of tetrahydrophthalic anhydride as nucleating agent for polypropylene beta crystal form

A technology of metal carboxylate and tetrahydrophthalic anhydride is applied in the field of nucleating agents, which can solve the problems of complex components and complex preparation methods, and achieve the effects of good dispersion, wide application conditions and improved impact strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

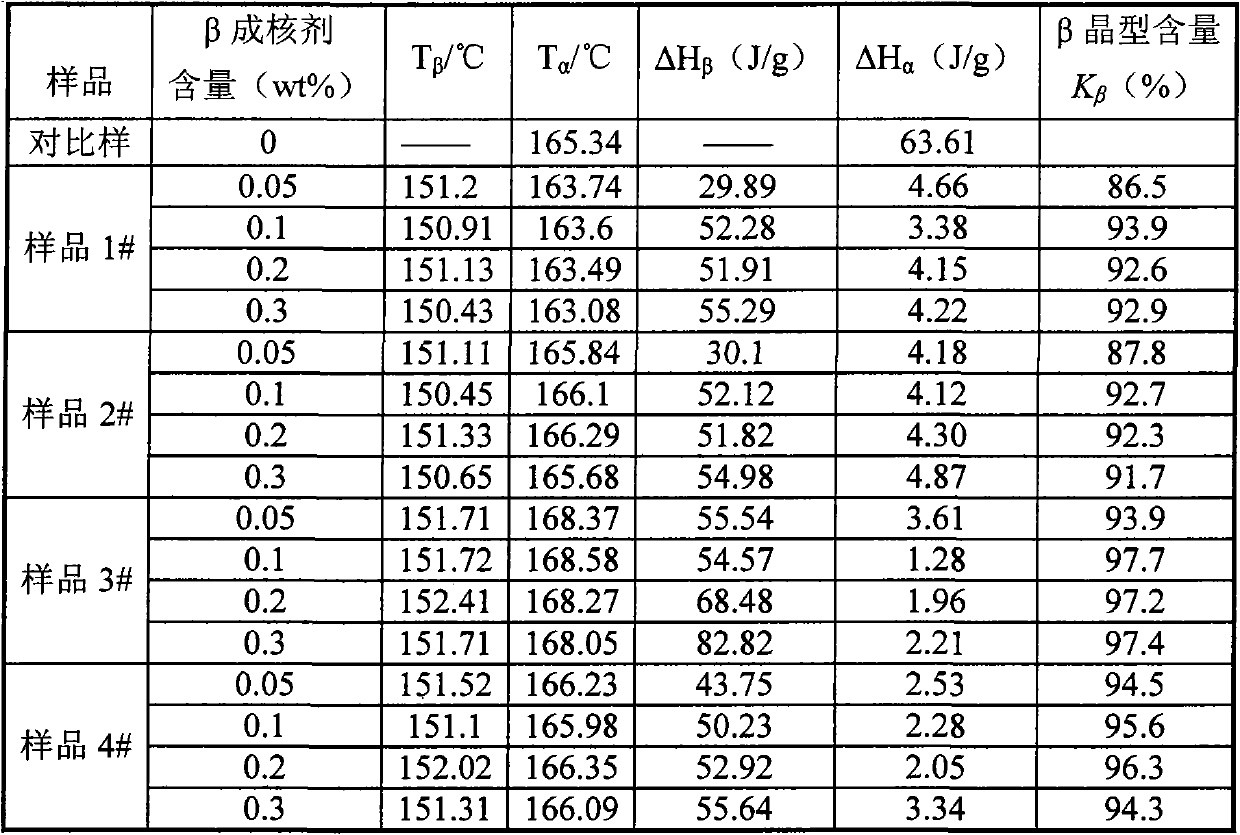

[0029] The present invention can be further illustrated by the following examples, but what is provided here are only the preferred embodiments of the present invention, and the scope of the present invention is not limited by this.

[0030] The polypropylene PP used in the following experiment is F401 produced by Sinopec Yangzi Petrochemical Co., Ltd.

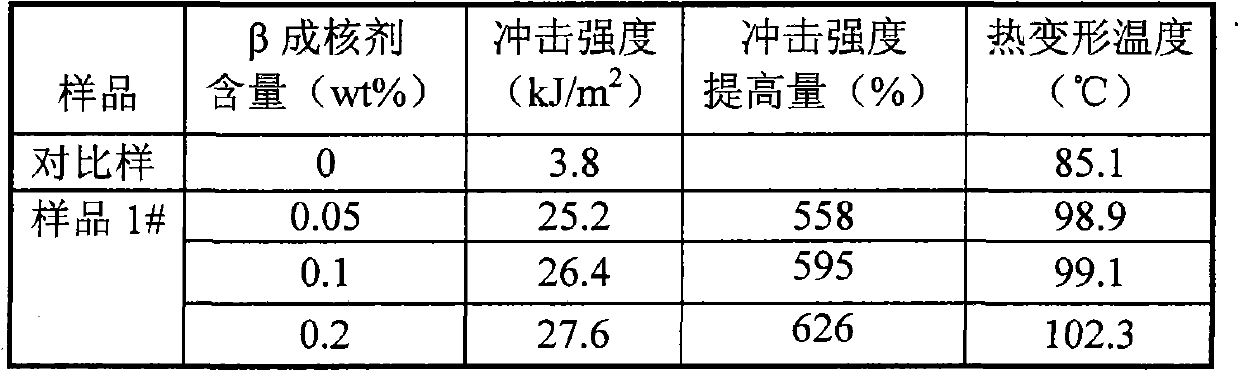

[0031] Preparation of sample 1#: Add the nucleating agent of calcium tetrahydrophthalate with a mass of 0.05%, 0.10%, 0.20% and 0.30% of the polypropylene mass to PP (F401) pellets (PP mass is 1000g as Benchmark), after mixing in a high-speed mixer for 5 minutes, twin-screw kneading and extrusion granulation, and then injection molding to make polypropylene PP (F401) standard sample strips. The extrusion temperature is 190-210℃, and the temperature of each section of the injection molding machine is 220-230℃.

[0032] Preparation of sample 2#: Add the nucleating agent of zinc tetrahydrophthalate with a mass of 0.05%, 0.10%, 0.20% an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com