Double-liquid fluorocarbon coating and preparation method and application thereof

A fluorocarbon coating and raw material technology, applied in the direction of coating, can solve the problems of poor recoatability, poor pigment dispersion, poor solvent solubility, etc., and achieve the best physical and mechanical properties, tough paint film, wear resistance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

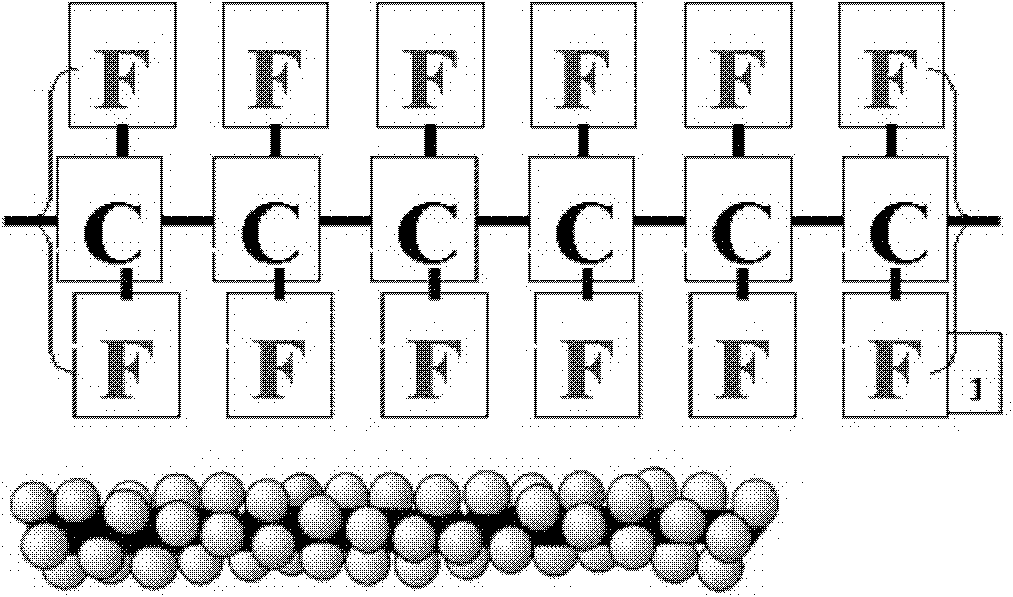

Method used

Image

Examples

Embodiment 1

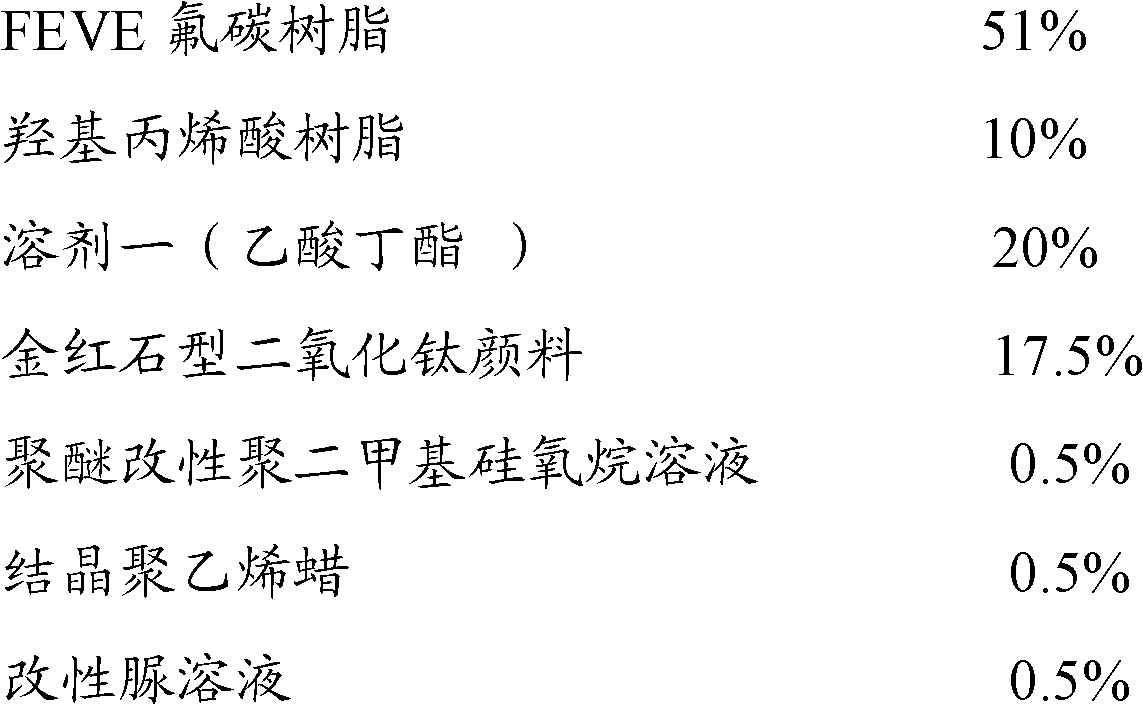

[0050] A high weather resistance two-component fluorocarbon white paint; comprising a mixture A and a mixture B, and the ratio of parts by weight of the mixture A to the mixture B is 100:10;

[0051] in,

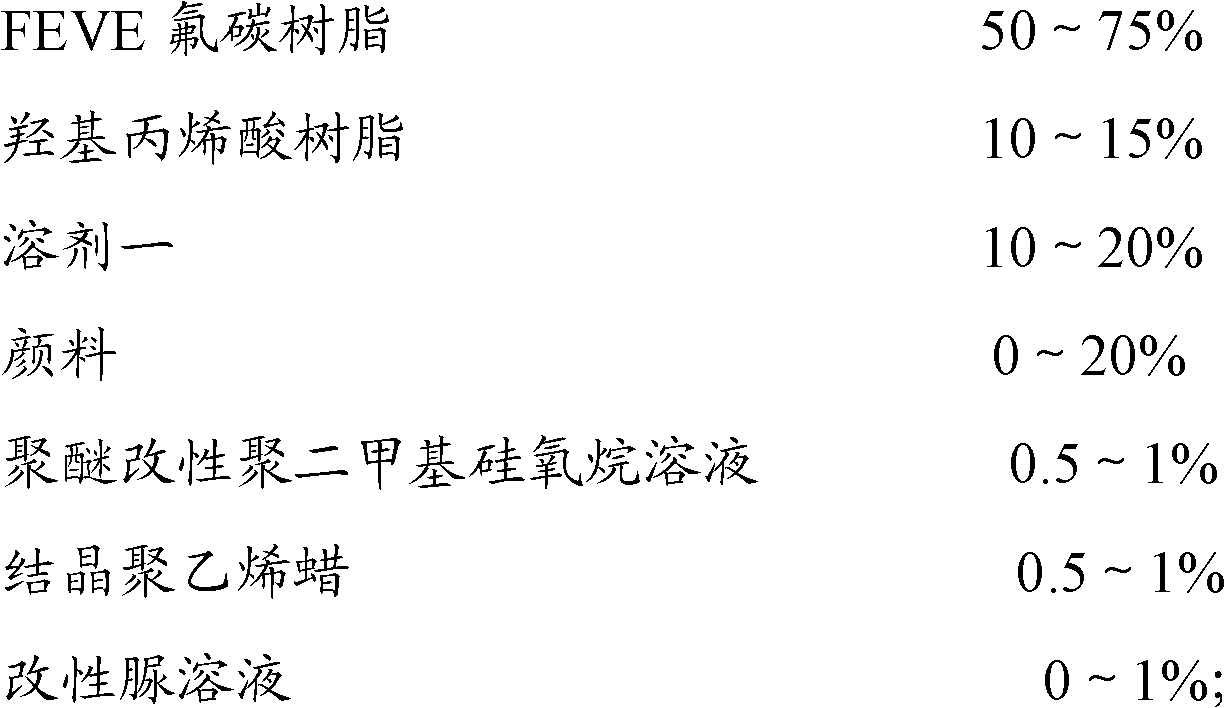

[0052] Described mixed material A comprises following raw material calculated by weight percentage:

[0053]

[0054] The mixed material B includes the following raw materials calculated by weight percentage:

[0055] Aliphatic polyisocyanate curing agent 70.8%

[0056] Solvent two (xylene, butyl acetate) 28.2%

[0057] Transparent colorless lipid denaturing aid 1.0%.

[0058] A two-component fluorocarbon coating for outdoor CCA panels; including the following preparation steps:

[0059] Step A. Put the amount of FEVE fluorocarbon resin, hydroxyacrylic resin, solvent one and rutile titanium dioxide pigment into the reaction kettle for mixing, and stir at 25±2°C for 30 minutes to prepare mixture I, wherein, The stirring speed is 1000 rpm;

[0060] Step B, transfer th...

Embodiment 2

[0064] A high weather resistance two-component fluorocarbon black paint; comprising a mixture A and a mixture B, and the ratio of parts by weight of the mixture A to the mixture B is 100:14;

[0065] in,

[0066] Described mixed material A comprises following raw material calculated by weight percentage:

[0067]

[0068] The mixed material B includes the following raw materials calculated by weight percentage:

[0069] Aliphatic polyisocyanate curing agent 70.8%

[0070] Solvent two (xylene, butyl acetate) 28.2%

[0071] Transparent colorless lipid denaturing aid 1.0%.

[0072] The preparation method is the same as in Example 1, wherein the high weather resistance carbon black powder is added in step A.

Embodiment 3

[0074] A two-component fluorocarbon black coating with high weather resistance and high scratch resistance; comprising a mixed material A and a mixed material B, and the weight and number ratio of the mixed material A to the mixed material B is 100:16;

[0075] in,

[0076] Described mixed material A comprises following raw material calculated by weight percentage:

[0077]

[0078] The mixed material B includes the following raw materials calculated by weight percentage:

[0079] Aliphatic polyisocyanate curing agent 70.8%

[0080] Solvent two (xylene, butyl acetate) 28.2%

[0081] Transparent colorless lipid denaturing aid 1.0%.

[0082] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com