One-component polyurethane skirt coating used for automotive

A one-component, polyurethane technology, used in polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor decoration, achieve high gloss retention, smooth surface, and improve light resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

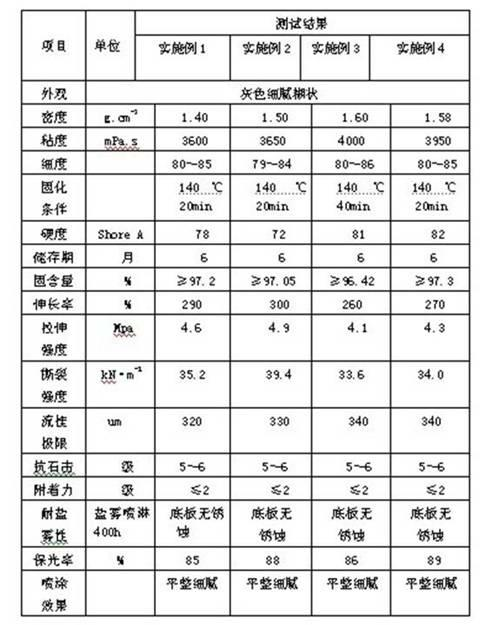

Examples

Embodiment 1

[0016] Example 1: Weigh 36 parts of polyether polyol, 38 parts of blocked isocyanate, 2 parts of dibutyltin dilaurate and stir evenly at a high speed, then add 8 parts of fumed white carbon black, 8 parts of 4A molecular sieve, nanocarbonic acid 10 parts of calcium, 10 parts of heavy calcium carbonate, 10 parts of talcum powder, and 1 part of gray paste are mixed evenly in a kneader, and then further dispersed by a three-roll mill to obtain a one-component polyurethane skirt coating.

Embodiment 2

[0017] Example 2: Weigh 36 parts of polyester polyol, 38 parts of blocked isocyanate, 2 parts of dibutyltin dilaurate and stir evenly at high speed, then add 8 parts of fumed white carbon black, 8 parts of 4A molecular sieve, nanocarbonic acid 20 parts of calcium, 20 parts of heavy calcium carbonate, 20 parts of talcum powder, and 1 part of gray paste are mixed evenly in a kneader, and then further dispersed by a three-roll mill to obtain a one-component polyurethane skirt coating.

Embodiment 3

[0018] Embodiment 3: Take by weight 36 parts of polyether polyols, 38 parts of blocked isocyanate, 2 parts of stannous octoate and stir evenly at high speed, add 8 parts of fumed white carbon black, 8 parts of calcium oxide powder, nanometer calcium carbonate 30 parts, 30 parts of light calcium carbonate, 30 parts of talcum powder, and 2 parts of gray paste are mixed evenly in a kneader, and then further dispersed by a three-roll mill to obtain a one-component polyurethane skirt coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com