Composite heat-insulating window

A technology of composite thermal insulation and thermal insulation sheet, which is applied in the direction of fire doors, etc., can solve the problems of difficult large-scale promotion and mass production, difficult manufacturing process, high cost, etc., to achieve light overall weight, low-carbon economy and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

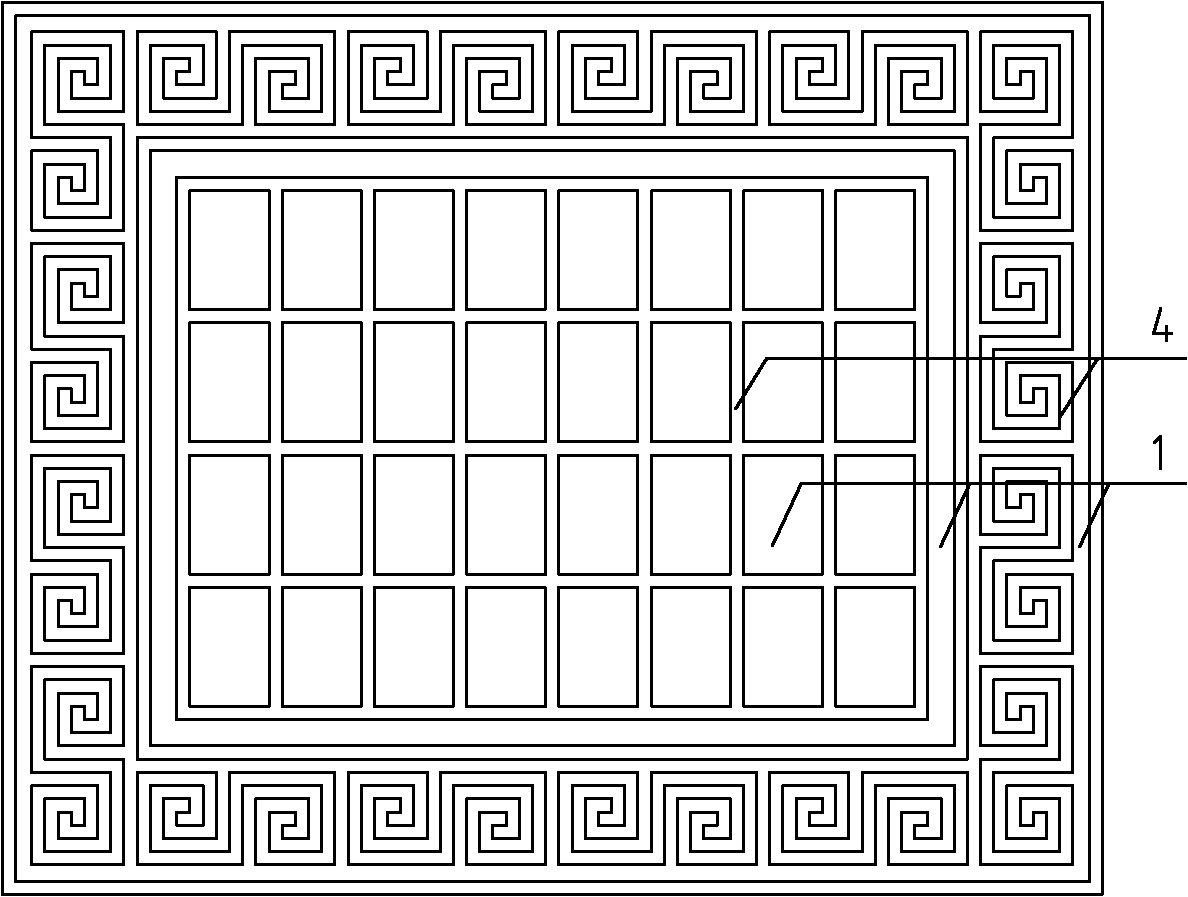

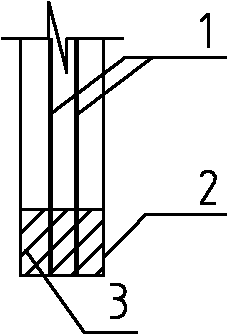

[0026] see Figure 1a ~ Figure 1c , Figure 1a ~ Figure 1c Shown is an insulating sheet fixed to the pane, covering the entire pane but not the frame. The thermal insulation sheet includes three layers of support frames 3 made of wood soaked in fireproofing liquid. Adjacent support frames 3 are bonded to each other. A light-transmitting sheet 1 is provided, and the light-transmitting sheet 1 is glued on the support frame 3 . The insulation sheet also has good air pressure regulation. The air pressure adjustment method is to have one or two small pressure-regulating holes with a diameter of 1 to 2 mm on a certain side frame of each layer of air grid, so that the internal air of the insulation sheet can pass through. The small pressure regulating hole on the support frame is connected with the outside.

[0027] In order to further improve the fireproof performance of the insulation sheet, a fireproof layer can be coated on the surface of the insulation sheet. In order to imp...

Embodiment 2

[0031] see Figure 2a ~ Figure 2c , the difference with embodiment 1 is: support frame 3 has four layers, is made of polyurethane, and the thickness of every layer of support frame is 6mm, and light-transmitting sheet has three layers, is made of PET transparent film, and thickness is 0.2mm. mm, the overall thickness of the formed thermal insulation sheet is 27mm, the shape of the pattern layer 4 glued to the light-transmitting sheet 1 is different, and the rest of the structure is the same as that of Embodiment 1.

[0032] The test results of the above-mentioned insulation window in the laboratory are: when the heat transfer coefficient is measured as 2.7 without the insulation sheet, the heat transfer coefficient is reduced to 0.9mm after the insulation sheet is added. The combustion performance of the insulation sheet is Class C.

Embodiment 3

[0034] see Figure 3a ~ Figure 3c , the difference with embodiment 1 is that: the support frame 3 has six layers, made of extruded polystyrene board, and the outside three-layer support frame 3 covers the window frame of the glass window, and the inside three-layer support frame 3 covers the The surrounding of the window glass does not cover the window frame of the glass window, so the thermal insulation effect is better; the thickness of each support frame is 8mm; the light-transmitting sheet has 5 layers, which is made of flame-retardant PC film, and the thickness is 0.1mm; The overall thickness of the formed thermal insulation sheet is 52mm; the shape of the pattern layer 4 glued on the transparent sheet 1 is different. All the other structures are identical to Embodiment 1.

[0035] The test results of the above-mentioned insulation window in the laboratory are: when the heat transfer coefficient is measured as 2.7 without the insulation sheet, the heat transfer coefficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com