Multiple fully-automatic large-horsepower high-speed integrated parallel and commercial power interconnection system and power supply method thereof

A fully automatic, high-speed technology, applied in the field of power systems, can solve the problems of exhaust emissions, waste heat utilization, difficulty in reasonable treatment, power supply process without timely and reasonable control, rough power supply functions, etc., to achieve unmanned operation, Avoid the waste of energy, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

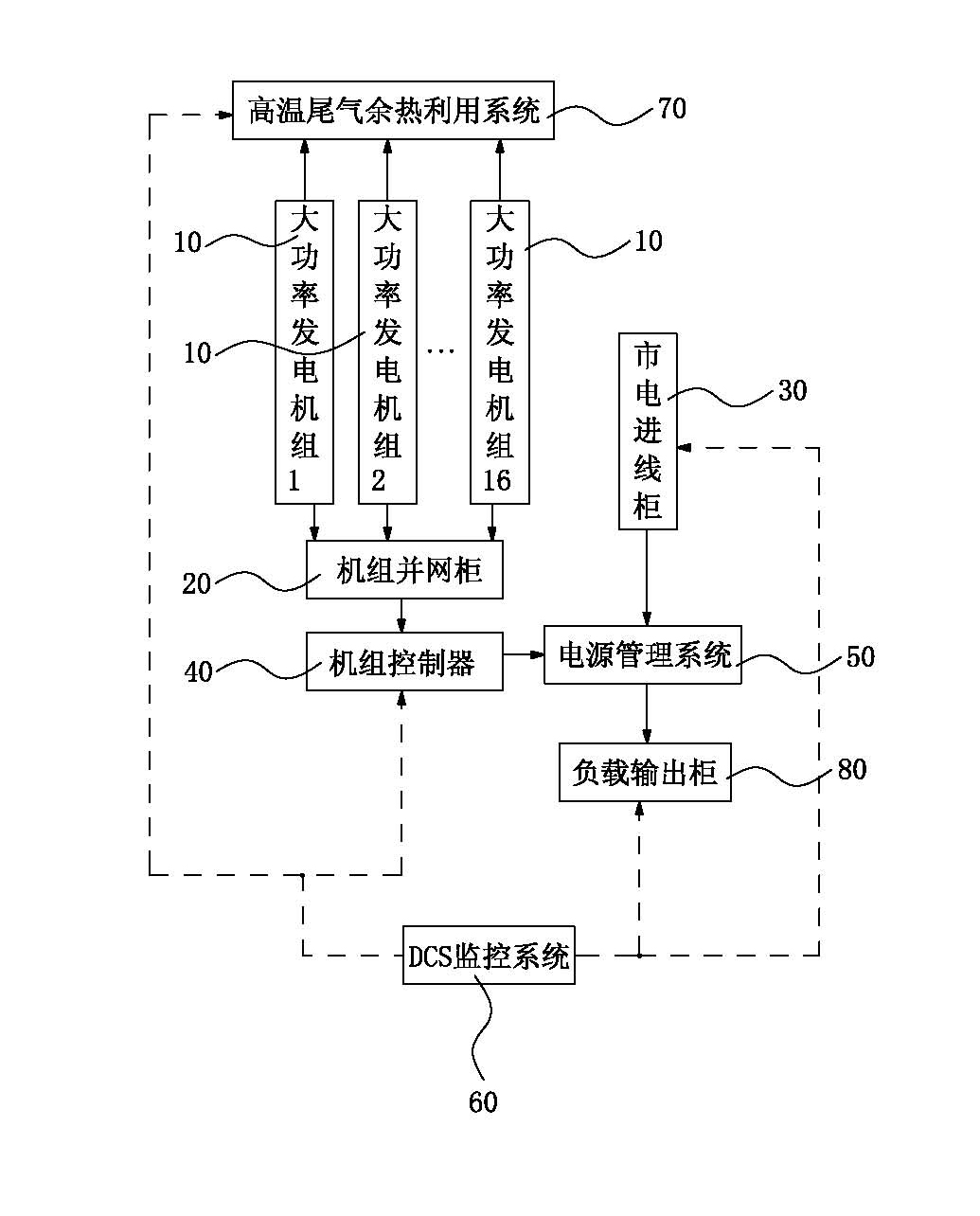

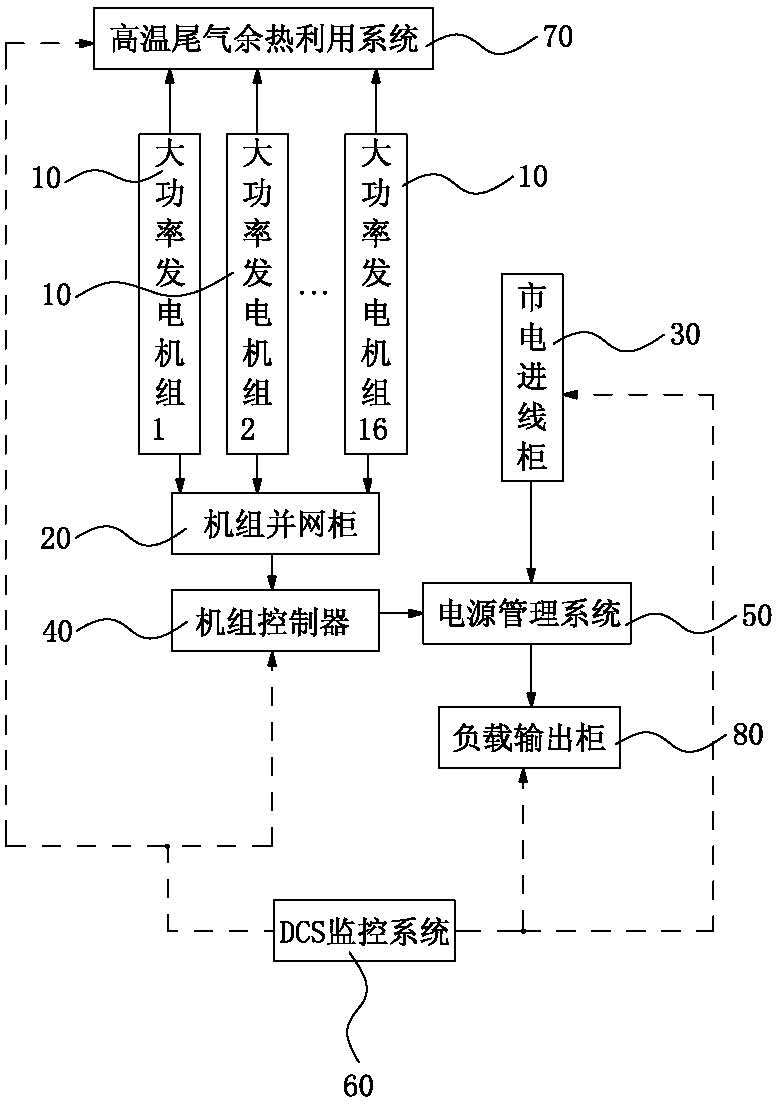

[0026] See figure 1 As shown, it shows the specific structure of the preferred embodiment of the present invention, which is mainly used in self-provided power stations in new industrial areas to realize power transmission (power sales), peak shifting, peak reduction, and utility power failure. Electricity, including high-power diesel generator set 10 (above 3000KW, its rated voltage is 400V, rated frequency is 50HZ), unit grid-connected cabinet 20, mains incoming cabinet 30, unit controller 40, power management system 50, DCS monitoring system 60, high temperature exhaust waste heat utilization system 70 and load output cabinet 80;

[0027] Wherein, the high-temperature exhaust waste heat utilization system 70 is connected to the aforementioned high-power diesel generator set 10, so that the waste heat is well utilized when generating electricity; the high-power diesel generator set 10 is two to sixteen, which are all connected to the unit and The network cabinet 20, the uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com