Three-phase bicirculating ozone catalytic fluidized bed and wastewater treatment method thereof

An ozone catalysis and fluidized bed technology, applied in the oxidation water/sewage treatment and other directions, can solve the problems of high labor intensity, high recovery rate and high operating cost, and achieve the effect of no secondary pollution, low cost and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

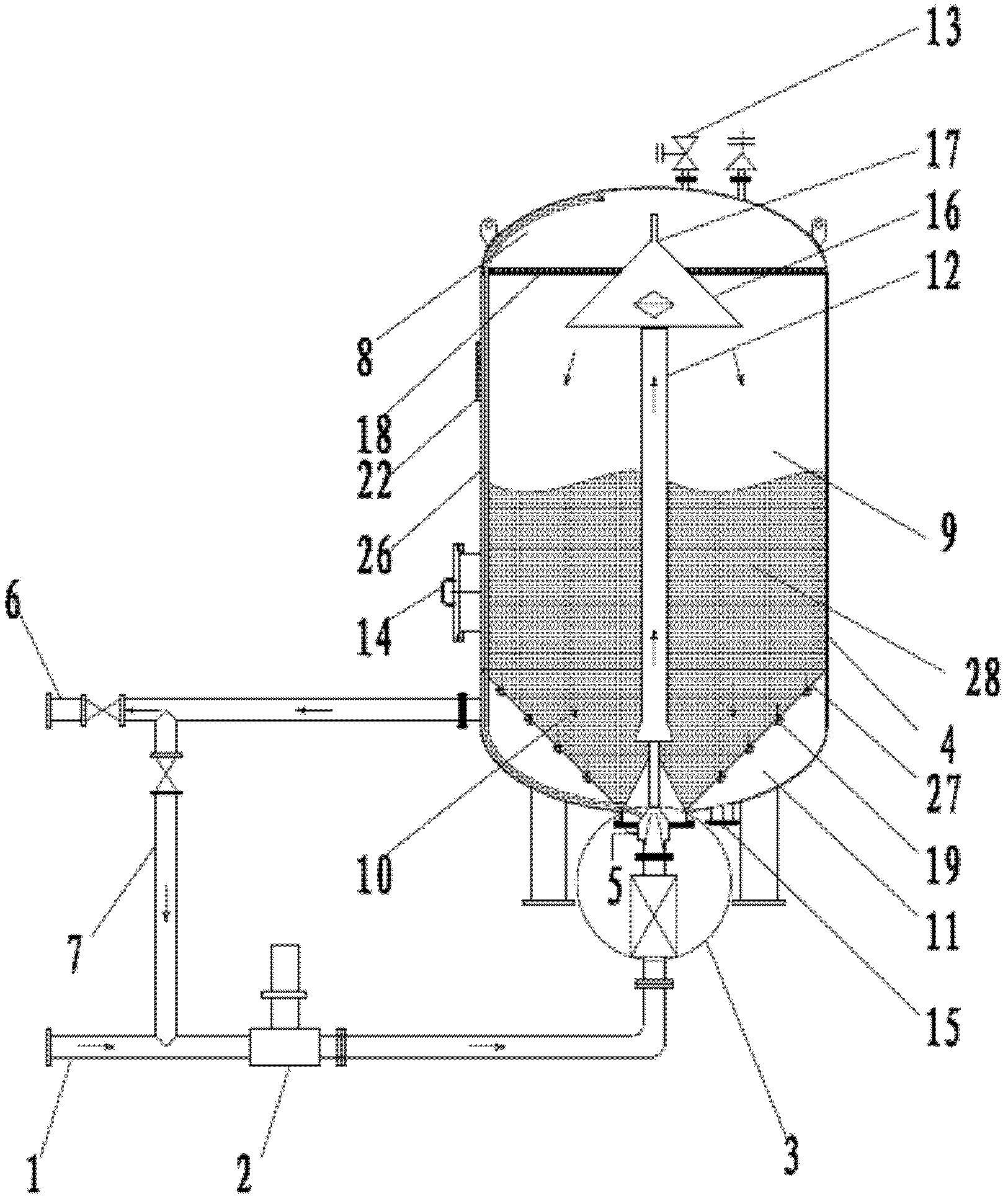

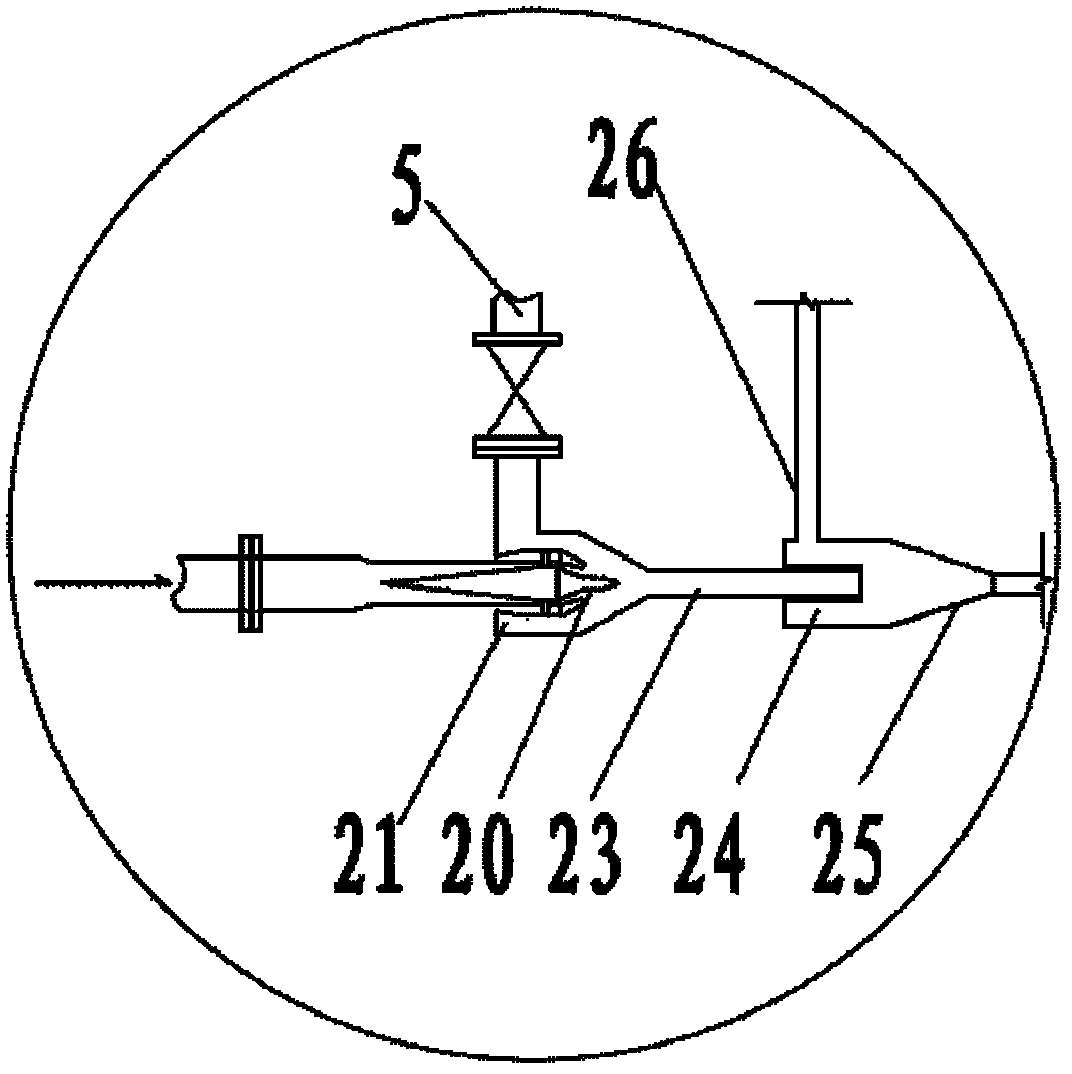

[0017] like figure 1 , figure 2 As shown, the three-phase double-circulation ozone catalytic fluidized bed provided by the present invention includes a water inlet pipe 1, a booster return pump 2, a jet aerator 3, a bed body 4, an ozone generator 5 and an outlet pipe 6, and the The water inlet pipe 1 is connected to the booster return pump 2, the booster return pump 2 is connected to the jet aerator 3, the jet aerator 3 is connected to the bed body 4, and the bed body 4 is provided with an outlet pipe 6 for jet aeration An ozone generator 5 is provided between the device 3 and the bed body 4, and a return pipe 7 is provided between the water inlet pipe 1 and the water outlet pipe 6; a gas dissipation layer 8, a circulating backflow outer cylinder 9, and a settling backflow pipe are arranged inside the bed body 4. chamber 10, filter clear liquid chamber 11 and diversion inner cylinder 12, the circulation backflow outer cylinder 9 is arranged under the gas dissipation layer 8,...

Embodiment 2

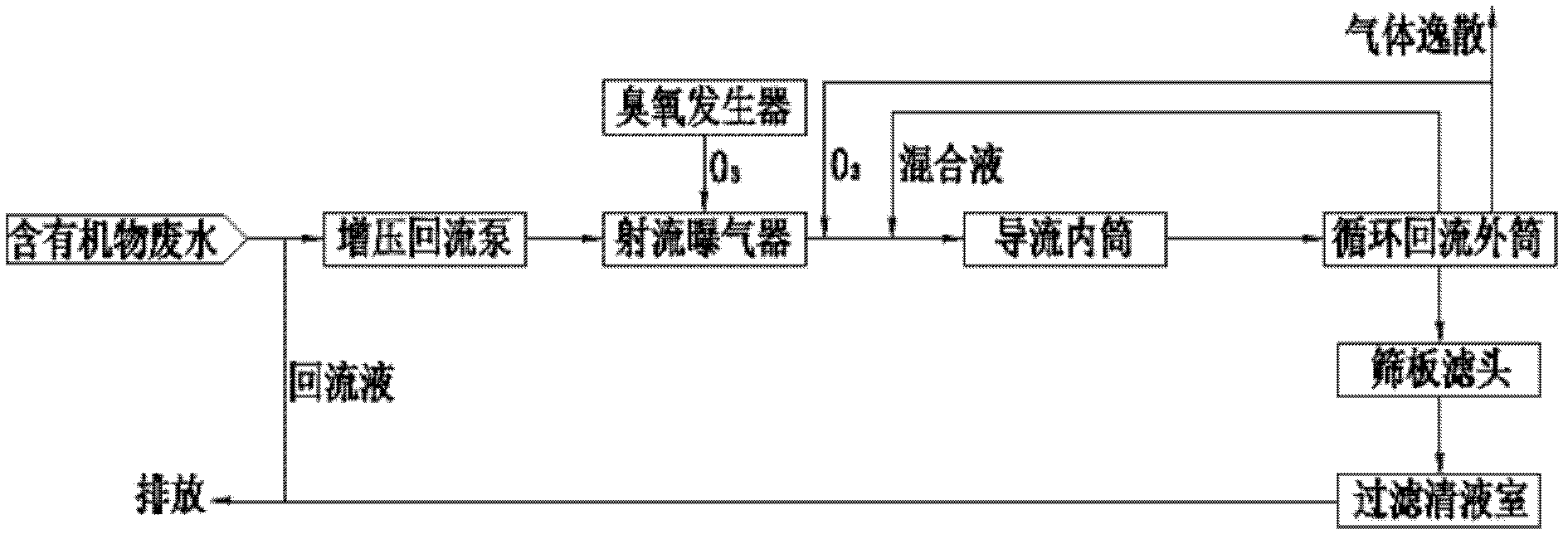

[0021] like image 3 As shown, the wastewater treatment method provided by the present invention adopts the three-phase double-circulation ozone catalytic fluidized bed, and the wastewater containing refractory organic matter enters the jet aerator 3 after being pressurized by the booster return pump 2 from the water inlet pipe 1 , through the primary nozzle 20 of the jet aerator 3, the primary mixing chamber 23 and the O 3 After the gas is fully contacted and mixed, it enters the secondary nozzle 25, and the O in the gas return pipe 26 is sucked through the secondary suction chamber 24 for the second time. 3 The remaining gas is released into the diversion inner cylinder 12 by secondary injection. Under the synergistic effect of injection kinetic energy, gas entrainment and entrainment promotion, and the density reduction caused by the increase of gas holdup, the water-gas-carrier The three-phase mixed liquid is fully mixed with the reflux liquid in the settling reflux chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com