Vanadium and titanium industrial wastewater treatment device

A technology for industrial waste water and treatment devices, applied in degassed water/sewage treatment, adsorption water/sewage treatment, neutralized water/sewage treatment, etc., capable of solving waste water discharge and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

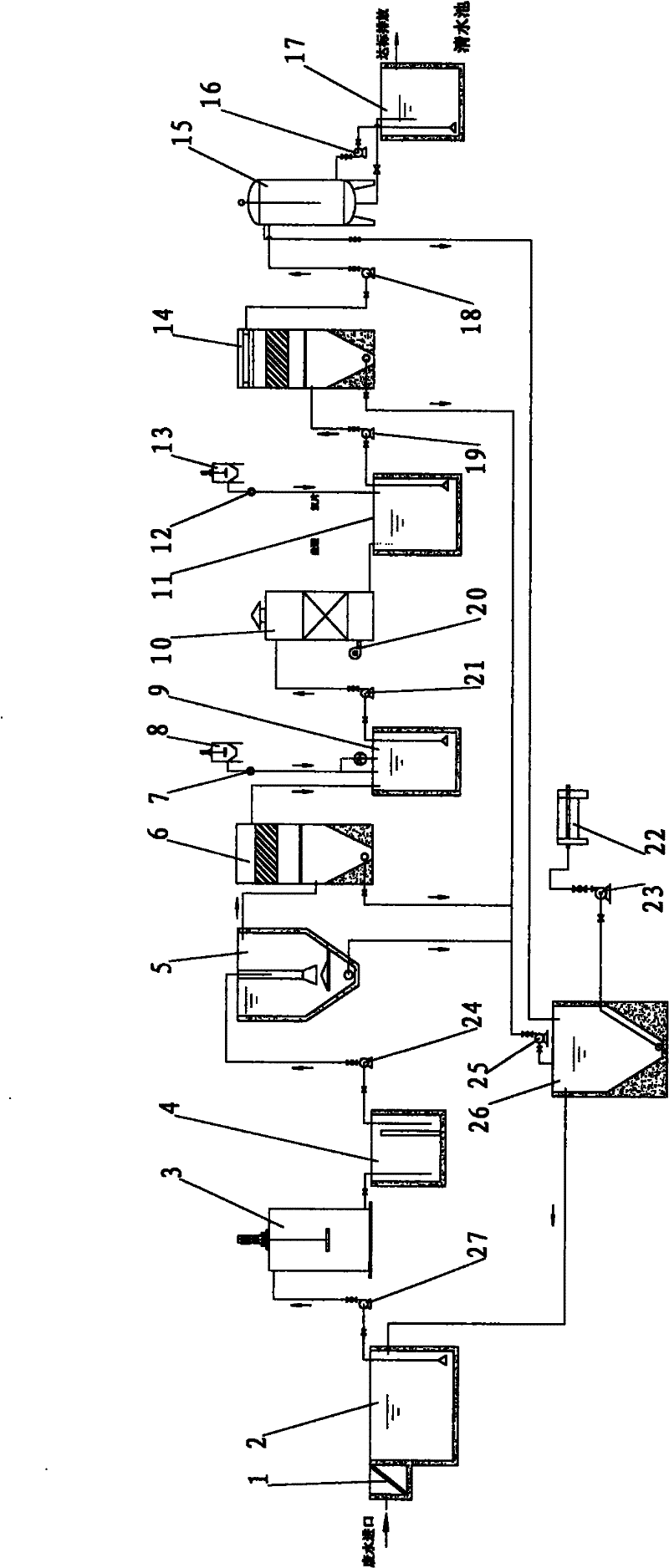

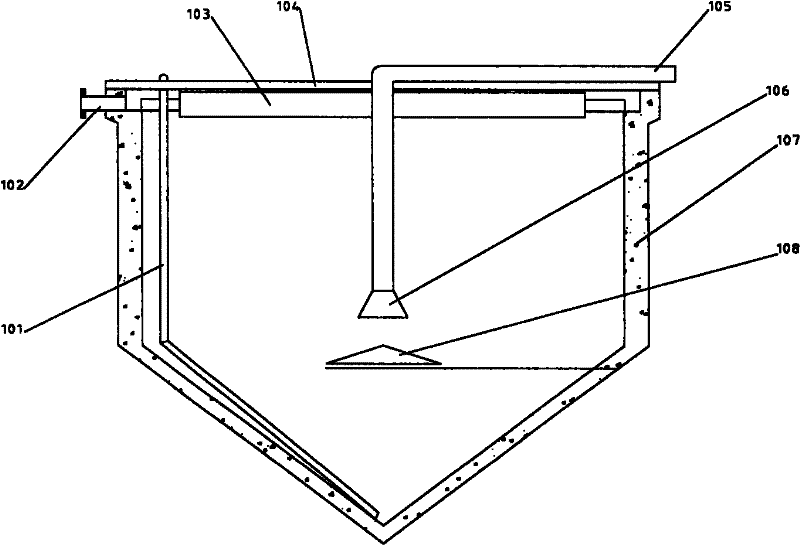

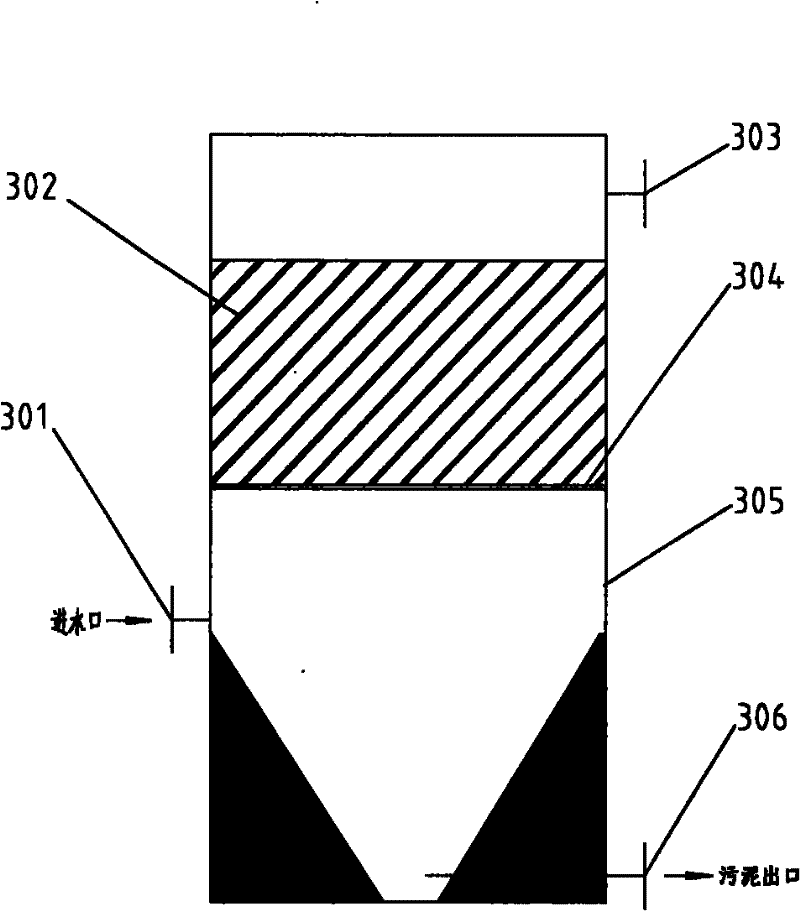

[0012] see Figure 1~5 , the present invention is provided with grille 1, adjusting pond 2, the 1st dosing box 3, the 2nd dosing box 8, the 3rd dosing box 13, sedimentation tank 4, vertical flow sedimentation tank 5, the 1st inclined tube sedimentation tank 6. The second inclined tube sedimentation tank 14, the first water pump 7, the second water pump 12, the recoil pump 16, the third water pump 18, the fourth water pump 19, the blower 20, the fifth water pump 21, the sixth water pump 24, and the mud pump 25. Intermediate pool 9, aeration tower 10, dosing pool 11, double material filter tower 15, filter press 22, screw pump 23, sludge thickening tank 26, sludge pump 27, etc. The waste water flows into the adjustment tank 2 through the grid 1, the water inlet of the sludge pump 27 is placed at the bottom of the adjustment tank 2, the outlet of the sludge pump 27 is connected to the first dosing tank 3, and the outlet of the first dosing tank 3 is connected to the sedimentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com