Epoxy resin composition

An epoxy resin and epoxy compound technology, applied in electrical components, circuits, electrical solid devices, etc., can solve the problem of high viscosity, and achieve the effects of high operability, excellent stability over time, and excellent long-term storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

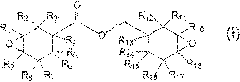

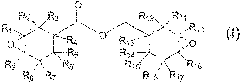

[0115] At room temperature, stir and mix the following components in a rotating and rotating mixer to prepare an adhesive composition: 3,4-epoxycyclohexylmethyl-3 as an alicyclic diepoxide compound, 4-epoxycyclohexane carboxylate (manufactured by Daicel Chemical Industry Co., Ltd., CELLOXIDE 2021P, R in general formula (I) 1 ~R 18 =H) 10.0 parts by weight; bisphenol F type epoxy resin (manufactured by Nippon Kayaku Co., Ltd., RE-303L) 10.0 parts by weight; methyl hexahydrophthalic anhydride (manufactured by New Japan Rika Co., Ltd., MH700, Acid anhydride equivalent: about 168) 23.3 parts by weight; imidazole epoxy resin addition curing agent (manufactured by Asahi Kasei E-materials, Novacure HX-3088) as a curing accelerator 1.2 parts by weight; γ-ring as a silane coupling agent 0.4 parts by weight of oxypropoxypropyltrimethoxysilane (manufactured by Tokyo Kasei Co., Ltd.); and silica SC4500-SQ (manufactured by Admatechs Co., Ltd.) as a filler, with an average particle size of 1....

Embodiment 2

[0117] Except for replacing the silica SC4500-SQ as a filler with silica SC4500-SEJ (manufactured by Admatechs Co., Ltd., average particle size 1.0μm, specific surface area 4.0m 2 / g, an adhesive composition was obtained in the same manner as in Example 1 except that the spherical fused silica surface-treated with γ-glycidoxypropyltrimethoxysilane) was 67.4 parts by weight.

Embodiment 3

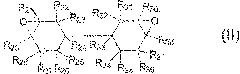

[0119] In addition to 3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexane carboxylate (manufactured by Daicel Chemical Industry Co., Ltd., CELLOXIDE 2021P, general formula (I) R in 1 ~R 18 =H) 10.0 parts by weight is replaced with bicyclohexyl-3,3'-diepoxide (R in general formula (II) 21 ~R 38 =H) An adhesive composition was obtained in the same manner as in Example 2 except for 10.0 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com