Process for preparing bio-diesel through fatty acid two-step esterifying method

A biodiesel and fatty acid technology, applied in fatty acid esterification, carboxylic acid ester preparation, organic compound preparation, etc., can solve the problems of high biodiesel, affecting the preparation of biodiesel, production of glycerol and saponification, etc., and achieve the speed of acid reduction Fast, short time, good acid-lowering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

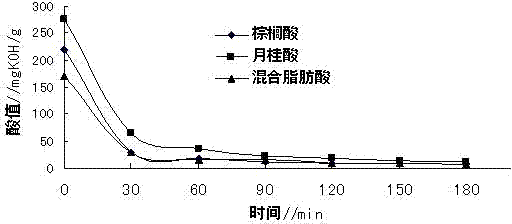

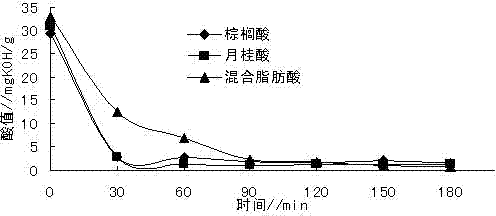

[0022] Step (1): Use a three-necked flask as an esterification reactor, add palmitic acid (analytical pure) with an initial acid value of 220 mgKOH / g, methanol, and sulfuric acid. The amount of methanol used is 80% of the weight of the fatty acid; the concentration of sulfuric acid is 98% and the amount used is 0.5% of the weight of the fatty acid. Stir continuously and heat to a temperature of 65±5°C. The raw materials are refluxed in the reaction device until the reaction reaches equilibrium or tends to Equilibrium, enter step (2) when the acid value is 29.5mgKOH / g.

[0023] Step (2): Continuously feed methanol liquid into the three-necked flask at a temperature of 100±5°C. The flow rate of methanol is 1.0mL / min. The condensation device recovers the water generated by esterification and excess methanol, and measures the acid value. When the acid value Stop the reaction when it is lower than 1.0mgKOH / g.

Embodiment 2

[0025] Taking the initial acid value of 275 mgKOH / g lauric acid (analytical pure) as the fatty acid, other parameters are shown in Table 1, and the steps are the same as in Example 1.

Embodiment 3

[0027] The waste oil was hydrolyzed with an initial acid value of 170 mgKOH / g (the waste oil was hydrolyzed by conventional methods to form fatty acids) into fatty acids, and the remaining parameters were shown in Table 1, and the steps were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com