Process for extracting vanadium from stone coal through two-section curing with concentrated acid

A fossil and concentrated acid technology, applied in the direction of improving process efficiency, etc., can solve problems such as waste of resources, low recovery rate, environmental pollution, etc., and achieve the effects of increasing conversion rate, improving leaching effect, and reducing leaching conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

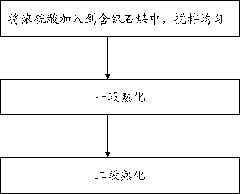

Method used

Image

Examples

Embodiment 1

[0049] Conventional experimental methods, such as X-fluorescence measurement, measure the grade of vanadium in the stone coal used in this embodiment to be 0.89%.

[0050] Grinding the above-mentioned stone coal 100g to be larger than 60 meshes, and mixing in 23% sulfuric acid with a concentration of 98%. Add water, control the liquid-solid ratio to 0.5, and stir evenly. One-stage aging at 50°C for 1 hour; second-stage aging at 120°C for 1.5 hours. Add water with a solid-to-liquid ratio of 2:1 to the solid obtained after the second-stage aging, then soak at 70° C. for 1 hour, filter, and wash with acidic warm water to obtain vanadium-containing leaching solution and leaching residue.

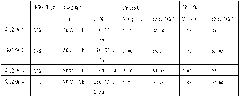

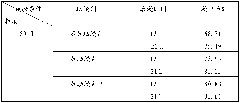

[0051] The ferrous ammonium sulfate solution with a concentration of 4 g / L was titrated in the vanadium-containing leaching solution, and the vanadium leaching rate was measured according to the conventional analytical chemical calculation method. The results are shown in Table 1.

Embodiment 2

[0053] The stone coal 100g identical with embodiment 1 is pulverized to more than 60 orders, and the sulfuric acid that the concentration that stirs in consumption is 17% is 98%. Add water, control the liquid-solid ratio to 0.5, and stir evenly. One-stage aging at 50°C for 1 hour; second-stage aging at 120°C for 1.5 hours. Add water with a solid-to-liquid ratio of 2:1 to the solid obtained after the second-stage aging, then soak at 70° C. for 1 hour, filter, and wash with acidic warm water to obtain vanadium-containing leaching solution and leaching residue.

[0054] Using the ferrous ammonium sulfate titration method as in Example 1, the vanadium leaching rate was measured, and the obtained results are shown in Table 1.

Embodiment 3

[0056] The stone coal 100g identical with embodiment 1 is pulverized to more than 60 orders, and the concentration that mixes in consumption is 23% is the sulfuric acid of 98%. Add water, control the liquid-solid ratio to 0.5, and stir evenly. One-stage aging at 70°C for 1 hour; second-stage aging at 100°C for 3 hours. Add water with a solid-to-liquid ratio of 2:1 to the solid obtained after the second-stage aging, then soak at 70° C. for 1 hour, filter, and wash with acidic warm water to obtain vanadium-containing leaching solution and leaching residue.

[0057] Using the ferrous ammonium sulfate titration method as in Example 1, the vanadium leaching rate was measured, and the obtained results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com